Field low-temperature-resistant composite cable insulation material and preparation method of same

A technology of composite cables and insulating materials, applied in the directions of insulators, insulated conductors, insulated cables, etc., can solve the problems of hindering the loss of heat of the cable, reducing the wear resistance of the surface, and accelerating the aging speed of the sheath, so as to achieve accelerated heat dissipation, Excellent thermal conductivity, heat dissipation capacity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of cable insulating material, the preparation method comprising:

[0034] 1) Preparation of insulating sleeve: mix alkyd resin, epoxy resin, cresol, butanol etherified amino resin, acrylic resin and ethyl acetate for the first mixing, the temperature of the first mixing is 50 -70°C, the first mixing time is 20-40min;

[0035] After the first mixing, add diatomaceous earth, polyethylene fiber, curing agent and plasticizer in sequence for the second mixing, the temperature of the second mixing is 100-110°C, the time of the second mixing 15-25min, the first insulating sleeve 1 and the second insulating sleeve 2 are obtained after compression molding;

[0036] 2) Preparation of heat pipe: mix polyvinylidene, paraffin, aluminum oxide and coupling agent KH550, then extrude to obtain heat pipe 3;

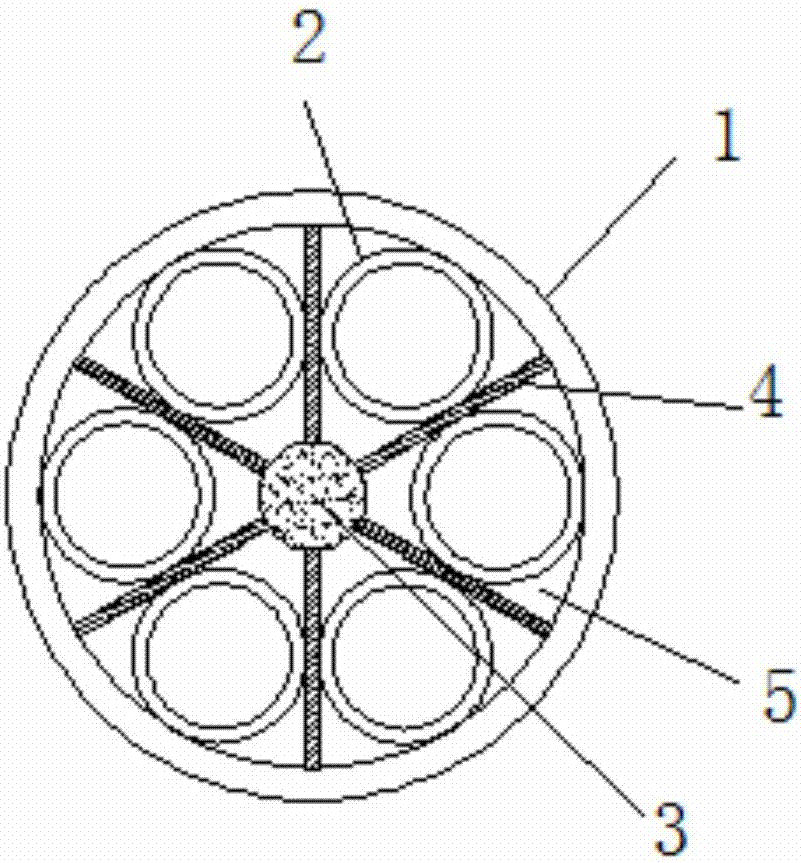

[0037] 3) Place the prepared heat pipe 3 in the first insulating sleeve 1, glue one end of the heat conducting sheet 4 to ...

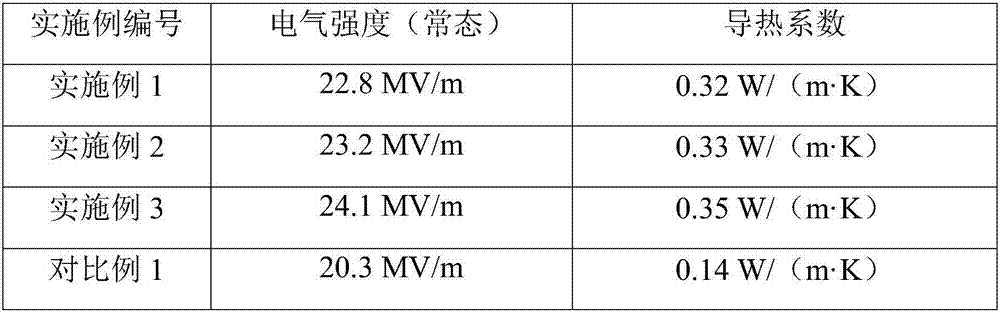

Embodiment 1

[0042]1) Preparation of insulating sleeve: Mix 100g alkyd resin, 20g epoxy resin, 5g cresol, 25g butanol etherified amino resin, 5g acrylic resin and 30g ethyl acetate, then mix for the first time. The mixing temperature is 50°C, and the first mixing time is 20 minutes; after the first mixing, add 2g of diatomaceous earth, 2g of polyethylene fiber, 2g of diethylenetriamine and 2g of dioctyl phthalate The ester is kneaded for the second time, the temperature of the second kneading is 100°C, and the time of the second kneading is 15 minutes, and the first insulating sheath 1 and the second insulating sheath 2 are obtained after compression molding;

[0043] 2) Preparation of heat pipe: mix 100g of polyvinylidene, 15g of paraffin, 5g of aluminum oxide and 2g of coupling agent KH550, then extrude to obtain heat pipe 3;

[0044] 3) Place the prepared heat pipe 3 in the first insulating sleeve 1, glue one end of the heat conducting sheet 4 to the outer wall of the heat pipe 3, and g...

Embodiment 2

[0047] 1) Preparation of insulating sleeve: Mix 100g alkyd resin, 40g epoxy resin, 12g cresol, 45g butanol etherified amino resin, 20g acrylic resin and 60g ethyl acetate, then mix for the first time. The mixing temperature is 70°C, and the first mixing time is 40 minutes; after the first mixing, add 10g of diatomaceous earth, 10g of polyethylene fiber, 5g of m-xylylenediamine and 5g of trimellitic acid tris The octyl ester is kneaded for the second time, the temperature of the second kneading is 110°C, and the time of the second kneading is 25 minutes, and the first insulating sheath 1 and the second insulating sheath 2 are obtained after compression molding;

[0048] 2) Preparation of heat pipe: mix 100g of polyvinylidene, 25g of paraffin, 12g of aluminum oxide and 8g of coupling agent KH550, and then extrude to obtain heat pipe 3;

[0049] 3) Place the prepared heat pipe 3 in the first insulating sleeve 1, glue one end of the heat conducting sheet 4 to the outer wall of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com