Seamless splicing production technology of leather

A production process and seamless splicing technology, which is applied in special leather manufacturing, composite leather, small raw leather/big raw leather/leather/fur treatment, etc. It can solve the problem of untrue printed patterns of luggage leather, easy peeling of the spliced layer, unattractive and durable And other problems, to achieve the effect of ensuring splicing fastness, strong three-dimensional sense, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 The following steps are adopted to realize the present invention:

[0026] (1) Use a shoveling machine to cut the leather in layers to obtain a surface with a thickness of 0.6mm;

[0027] (2) Cover the cut surface of the dough with a layer of hot melt adhesive TPU film, and use a hot press for the first hot pressing. The pressure of the hot press is 0.3par, the temperature is 120℃, and the first hot pressing time is 15s. After cooling for 5 minutes;

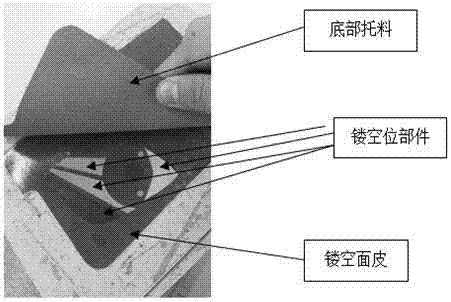

[0028] (3) Use the shape mold to cut the dough after the first heat pressing and cooling to obtain the hollow dough and hollow parts, and cut the distance between the outer contour line and the inner contour line of the figure using the shape mold, that is, the graphic The line thickness is 0.1mm, so that when the obtained hollow part is filled in the corresponding hollow part on the hollow surface, the gap between the figure of the hollow part and the corresponding hollow part is 0.1mm;

[0029] (4) Fill the hollow par...

Embodiment 2

[0030] Embodiment 2 The following steps are adopted to realize the present invention:

[0031] (1) Use a shoveling machine to cut the leather in layers to obtain a dough with a thickness of 0.5mm;

[0032] (2) Cover the cut surface of the dough with a layer of hot melt adhesive TPU film, and use a hot press for the first hot pressing. The pressure of the hot press is 0.2par, the temperature is 110°C, and the first hot pressing time is 10s. After cooling for 3 minutes;

[0033] (3) Use the shape mold to cut the dough after the first hot pressing and cooling to obtain the hollow dough and hollow parts, and cut the distance between the outer contour line and the inner contour line of the figure using the shape mold, that is, the graphic The line thickness is 0.05mm, so that when the obtained hollow part is filled in the corresponding hollow part on the hollow surface, the gap between the figure of the hollow part and the corresponding hollow part is 0.05mm;

[0034] (4) Fill the hollow ...

Embodiment 3

[0035] Embodiment 3 The following steps are adopted to realize the present invention:

[0036] (1) Use a shoveling machine to cut the leather in layers to obtain a dough with a thickness of 0.7mm;

[0037] (2) Cover the cutting surface of the dough with a layer of hot melt adhesive TPU film, and use a hot press for the first hot pressing. The pressure of the hot press is 0.4par, the temperature is 125°C, and the first hot pressing time is 20s. After cooling for 6 minutes;

[0038] (3) Use the shape mold to cut the dough after the first heat pressing and cooling to obtain the hollow dough and hollow parts, and cut the distance between the outer contour line and the inner contour line of the figure using the shape mold, that is, the graphic The line thickness is 0.2mm, so that when the obtained hollow part is filled in the corresponding hollow part on the hollow surface, the gap between the figure of the hollow part and the corresponding hollow part is 0.2mm;

[0039] (4) Fill the holl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com