Waste hydrothermal recycler with anti-blocking function and using method thereof

A technology of heat recovery and heat recovery, applied in heat exchanger types, indirect heat exchangers, damage protection, etc., can solve problems affecting heat exchange efficiency, poor heat exchange effect, pipeline blockage, etc., and achieve enhanced heat exchange efficiency , production difficulty is small, the effect of strengthening heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

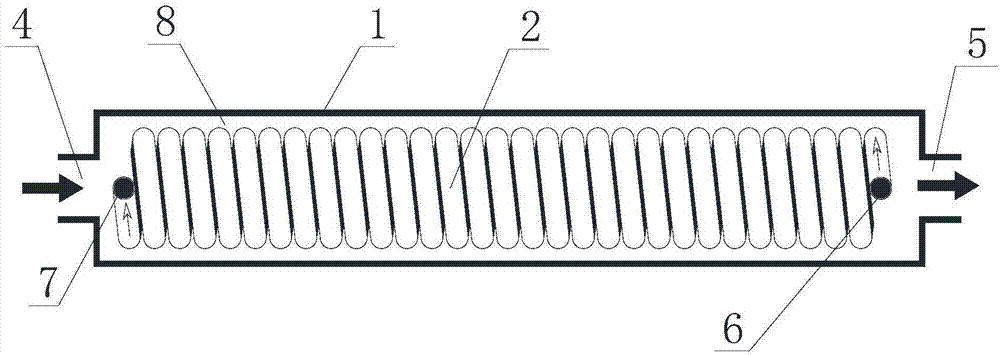

[0025] Such as figure 1 As shown, the wastewater heat recovery device with anti-blocking function includes the heat recovery bellows 2 installed in the sewage pipe 1, which adopts the countercurrent method to improve the heat exchange efficiency, so the water flow direction in the heat recovery bellows 2 and The direction of water flow in the sewage pipe 1 is opposite, and at the same time, the two ends of the heat recovery bellows 2 are respectively close to the two ends of the sewage pipe 1, which not only realizes maximum contact, but also reduces heat waste. The two ends of the sewage pipe 1 are respectively named as the waste water inlet 4 and the waste water outlet 5 according to the direction in which the waste water 8 enters and exits, and the two ends of the heat recovery bellows 2 are respectively named as the cold water inlet 6 and Warm water outlet 7, according to the pipe layout method of heat recovery cold water and waste hot water, the cold water inlet 6 is at t...

Embodiment 2

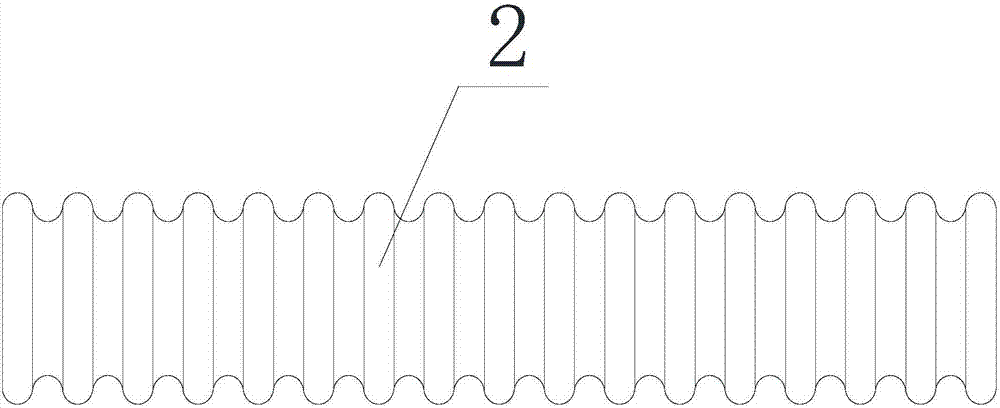

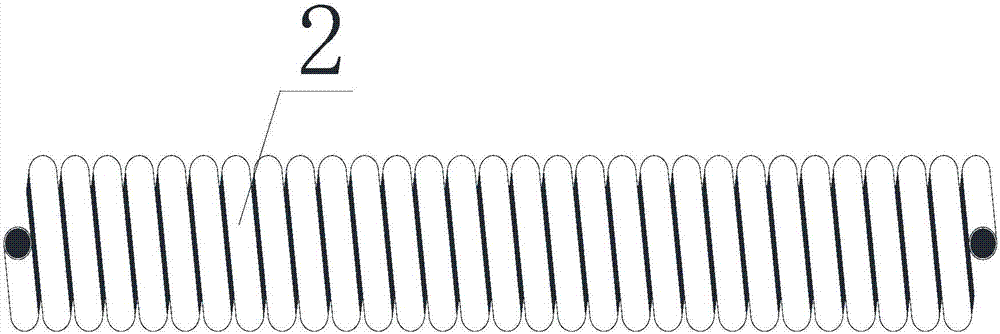

[0027] Such as figure 2 , image 3As shown, on the basis of Example 1, the heat recovery bellows 2 made of thin-walled stainless steel is formed into a spiral structure, and the spiral structure is coaxial with the sewage pipe 1. In the spiral structure formed by the heat recovery bellows 2 There are gaps between the outer walls of adjacent bellows rings. The heat recovery corrugated pipe 2 will automatically form a certain elastic stress when it is formed into a spiral shape. This stress can make the heat recovery corrugated pipe 2 close to the inner wall of the sewage pipe 1, making it difficult to move. When the heat recovery corrugated pipe 2 is formed into a spiral pipe The elastic stress will also make each ring of bellows form a certain fixed gap. The gap allows the heat recovery bellows 2 to exchange heat with the sewage pipe 1 to form an effective spiral guide for the waste hot water in the sewage pipe, and strengthen the heat exchange between the waste water and t...

Embodiment 3

[0029] Such as Figure 4 , Figure 5 As shown, on the basis of the above-mentioned embodiments, a cleaning device for flushing the outer wall of the heat recovery bellows 2 is provided under the heat recovery bellows 2 and in the sewage pipe 1. In consideration of cost and cleaning convenience, high pressure is preferred. The way of air injection, so the cleaning device includes a compressed air pipe 3, on which several nozzles 9 are arranged, and the nozzles 9 are arranged symmetrically along the axis of the compressed air pipe 3, and the sprayed area of all nozzles 9 can cover the entire Root heat recovery bellows 2. The compressed air nozzle 9 is used for manual or automatic air injection, which can promptly and effectively clean the dirt on the wall of the heat recovery bellows 2, so that the heat recovery device can operate efficiently for a long time. The jet of air through the nozzle 9 can effectively disturb the waste hot water 8 in the sewage pipe, form a strong e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com