A kind of preparation method of nuclear fuel silicon carbide ceramic cladding tube

A technology for nuclear fuel silicon carbide and silicon carbide ceramics, which is applied in nuclear engineering, reactors, shielding, etc., can solve the problems of inconsistent pipe wall thickness, difficult and uniform deposition on the inner wall of pipe fittings, etc., and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

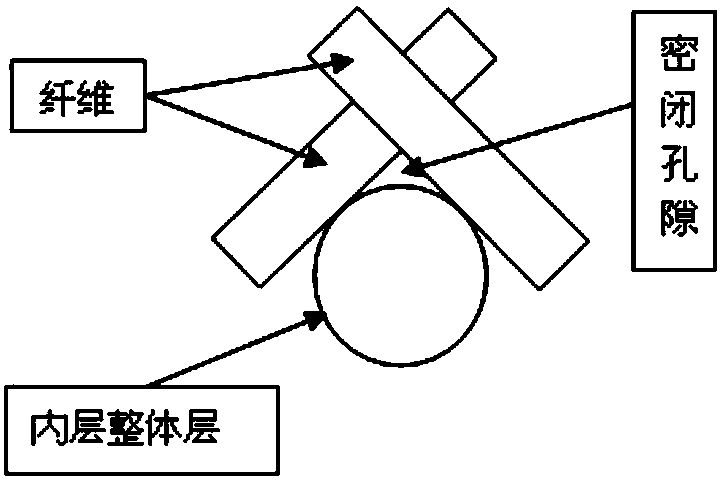

[0025] (1) Making winding or braiding parts: winding or braiding silicon carbide fibers on short-sized mandrels, and depositing pyrolytic carbon coatings, but not limited to fiber surface treatments such as pyrolytic carbon coatings. In the embodiment, the size of the mandrel can be but not limited to Φ8×1000 mm mandrel, and the thickness of the winding or weaving can be but not limited to 0.5 mm. In the embodiment, the thickness of the pyrolytic carbon coating can be but not limited to 0.5 micron.

[0026] (2) Pressurized impregnation and cross-linking: Put the above-mentioned winding or braided parts into a closed mold cavity, use VRTM process vacuum-assisted injection to impregnate liquid polycarbosilane, and keep the injection pressure and heat up to the cross-linking temperature for cross-linking and curing. In the embodiment, the mold cavity size can be but not limited to Φ9×1000mm, the liquid polycarbosilane can be but not limited to 1:1 xylene dissolved solid silane so...

Embodiment 2

[0031] A method for preparing a nuclear fuel silicon carbide ceramic cladding tube, characterized in that the method adopts the following steps:

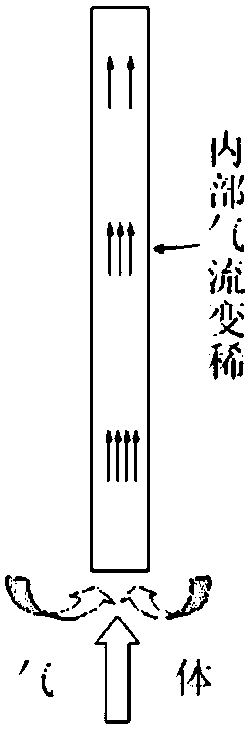

[0032] (1) Manufacture of composite material intermediate layer pipe fittings: use pressure impregnation crosslinking to prepare silicon carbide fiber ceramic composite layer pipe fittings on the mold core, put the winding or braided parts into a closed mold cavity, and use VRTM process vacuum assisted injection impregnation Liquid polycarbosilane, keep the injection pressure and heat up to the crosslinking temperature for crosslinking and curing. The cavity size can be but not limited to Φ9×400mm. The liquid polycarbosilane is LPVCS, and xylene can be used to dissolve the solid silane solution at 1:1, and inject The pressure is 0.02Mpa, the cross-linking and curing temperature is 250°C, and then the densification treatment is carried out. The pipe fittings with mold cores are cracked at 1100°C under the protection of nitrogen. After...

Embodiment 3

[0036] A method for preparing a nuclear fuel silicon carbide ceramic cladding tube, characterized in that the method adopts the following steps:

[0037] (1) Manufacture of composite material intermediate layer pipe fittings: use pressure impregnation crosslinking to prepare silicon carbide fiber ceramic composite layer pipe fittings on the mold core, put the winding or braided parts into a closed mold cavity, and use VRTM process vacuum assisted injection impregnation Liquid polycarbosilane, keep the injection pressure and heat up to the crosslinking temperature for crosslinking and curing. The cavity size is Φ9×400mm. The liquid polycarbosilane is LPVCS. You can also use xylene to dissolve the solid silane solution at a ratio of 1:1. The injection pressure is 0.1Mpa. , The crosslinking curing temperature is 180°C. Then carry out densification treatment. Under the protection of nitrogen, the pipe fittings with mold cores are cracked at 1200°C. After cracking, the PIP method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com