Oil sludge pyrolysis continuous feeding device

A feeding device and pyrolysis technology, which is applied in pyrolysis treatment of sludge, petroleum industry, indirect heating and dry distillation, etc., can solve problems such as poor fluidity, high sludge viscosity, and inability to transport sludge, and achieve error elimination, low cost, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the embodiments of the invention shown in the exemplary embodiments are illustrative only. Although only a few embodiments have been described in detail in the present invention, those skilled in the art will readily appreciate that many modifications are possible without materially departing from the teachings of the subject matter of the invention. Accordingly, all such modifications are intended to be included within the scope of this invention. Other substitutions, modifications, changes and deletions can be made to the designs, operating conditions and parameters of the following exemplary embodiments without departing from the gist of the present invention.

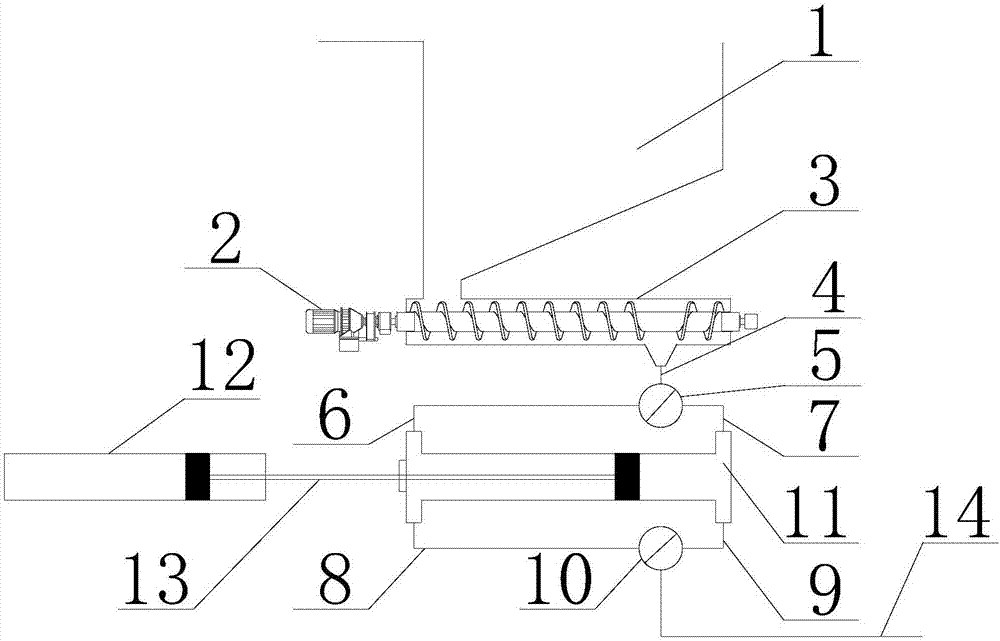

[0029] Such as figure 1 The shown oil sludge pyrolysis continuous feeding device has a storage bin 1, the storage bin 1 has an inlet and an outlet, and an arch breaking device (not shown) is arranged in the storage bin 1 to prevent the oil sludge from entering the The cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com