Continuous preparing technology for dimethyl dicarbonate

A technology for the preparation of dimethyl dicarbonate, which is applied in the preparation of carbonate/haloformate, the preparation of organic compounds, the purification/separation of carbonate/haloformate, etc., to achieve low cost , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

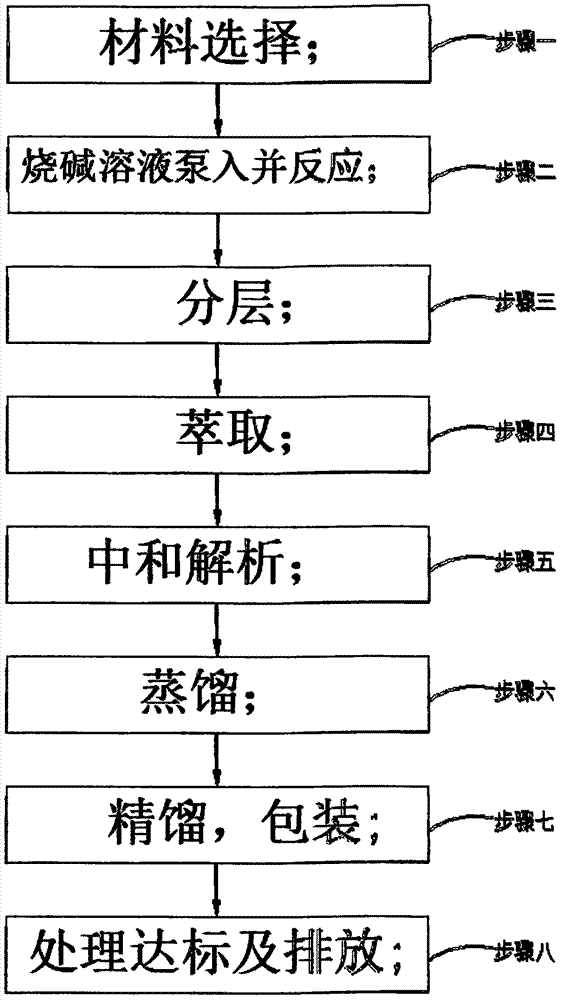

[0028] Examples such as figure 1 As shown, a continuous preparation process of dimethyl dicarbonate includes the following steps: Step 1, material selection; Step 2, caustic soda solution is pumped in and reacted; Step 3, layering; Step 4, extraction; Step 5 , neutralization analysis; Step 6, distillation; Step 7, rectification, packaging; Step 8, treatment up to standard and discharge.

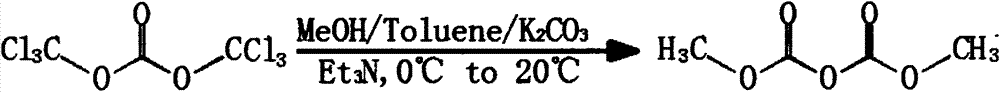

[0029] Wherein in described step one, selection material is organic solvent toluene, phase-transfer catalyst and methyl chloroformate, and organic solvent toluene, phase-transfer catalyst and methyl chloroformate three feed molar ratio catalyst: toluene: methyl chloroformate Esters=1:(50-150):(100-260).

[0030] In the second step, 14%-20% caustic soda solution is continuously pumped in and reacted at a constant temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com