Preparation method of hyper-branched macromolecular adhesion promoter for paint

A technology of hyperbranched polymers and adhesion promoters, applied in the direction of coating, etc., can solve the problems of restricting wide application, limited application occasions, poor storage stability, etc., to improve molecular bonding performance, enhance adhesion performance, enhance phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of hyperbranched polymer adhesion promoter for coating of the present invention comprises the steps:

[0028] (1) Synthesis of polyhydroxyl hyperbranched polymers

[0029] a) under normal temperature and pressure, respectively add polyol ether, polybasic acid and first catalyst in the four-necked flask equipped with agitator and condensing device, then feed nitrogen into the four-necked flask, and then stir for 10-20 minutes;

[0030] b) Raise the temperature of the four-neck flask to 90-250°C, and keep stirring under normal pressure for 1-10 hours, then turn off the nitrogen, vacuumize for 1-5 hours, and let the mixture stand still to cool to room temperature naturally. Hydroxy hyperbranched polymers;

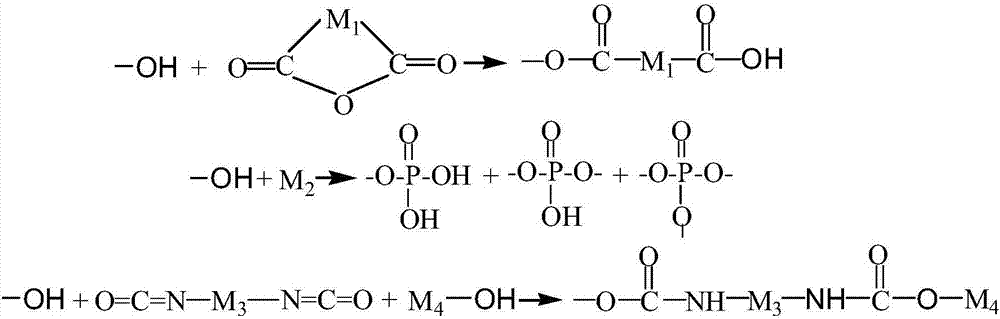

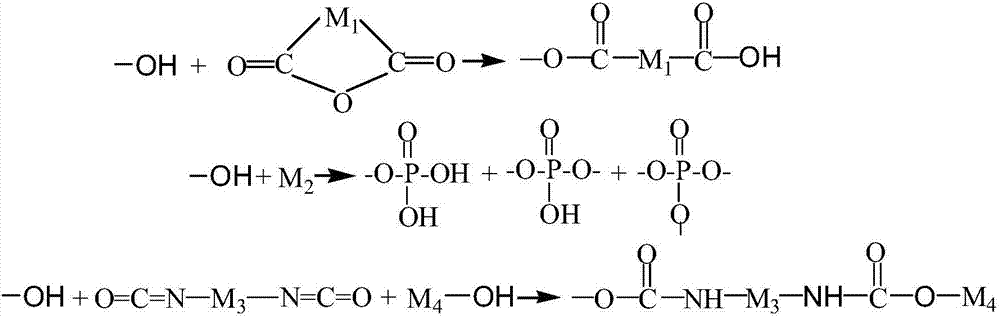

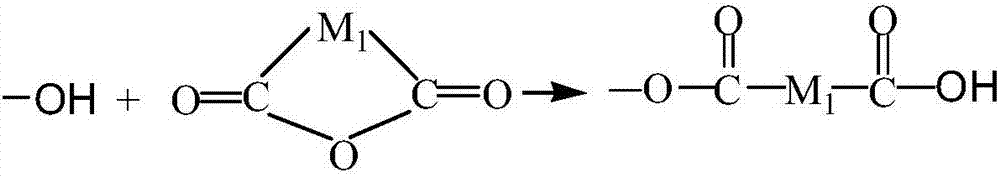

[0031] (2) Modification of polyhydroxyl hyperbranched polymers

[0032] c) Add a modifying agent and a second catalyst to the polyhydroxyl hyperbranched polymer obtained in step c, stir at 50-200° C. for 1-10 hours, and the molar ratio of the mo...

Embodiment 1

[0046] The preparation method of hyperbranched polymer adhesion promoter for coating of the present invention comprises the steps:

[0047] (1) Synthesis of polyhydroxyl hyperbranched polymers

[0048] a) under normal temperature and pressure, add polyol ether, polybasic acid and first catalyst respectively in the four-necked flask that is provided with agitator and condensing device, then feed nitrogen into the four-necked flask, and then stir for 20 minutes;

[0049] b) Raise the temperature of the four-necked flask to 140°C, and continue to stir for 3 hours under normal pressure, then turn off the nitrogen gas, then vacuumize the four-necked flask for 1 hour, and let the mixture cool naturally to room temperature to obtain more hydroxyl groups. hyperbranched polymers;

[0050] (2) Modification of polyhydroxyl hyperbranched polymers

[0051] c) Add a modifier and a second catalyst to the polyhydroxyl hyperbranched polymer obtained in step c, stir at 120° C. for 6 hours, an...

Embodiment 2

[0062] The preparation method of hyperbranched polymer adhesion promoter for coating of the present invention comprises the steps:

[0063] (1) Synthesis of polyhydroxyl hyperbranched polymers

[0064] a) under normal temperature and pressure, add polyol ether, polybasic acid and first catalyst respectively in the four-necked flask that is provided with agitator and condensing device, then feed nitrogen into the four-necked flask, and then stir for 20 minutes;

[0065] b) Raise the temperature of the four-necked flask to 250°C, and continue to stir for 8 hours under normal pressure, then turn off the nitrogen gas, then vacuumize the four-necked flask for 2 hours, and let the mixture cool naturally to room temperature. Hydroxy hyperbranched polymers;

[0066] (2) Modification of polyhydroxyl hyperbranched polymers

[0067] c) Add a modifier and a second catalyst to the polyhydroxyl hyperbranched polymer obtained in step c, stir at 50°C for 3 hours, and the molar ratio of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com