Modified general type emulsion paint and preparation method thereof

A general-purpose, latex paint technology, applied in latex paint, coating, etc., can solve the problems of high construction requirements, harsh walls, difficulty in showing elegance, fineness, and refinement, etc., and achieve low construction requirements and balanced shear viscosity , smooth gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

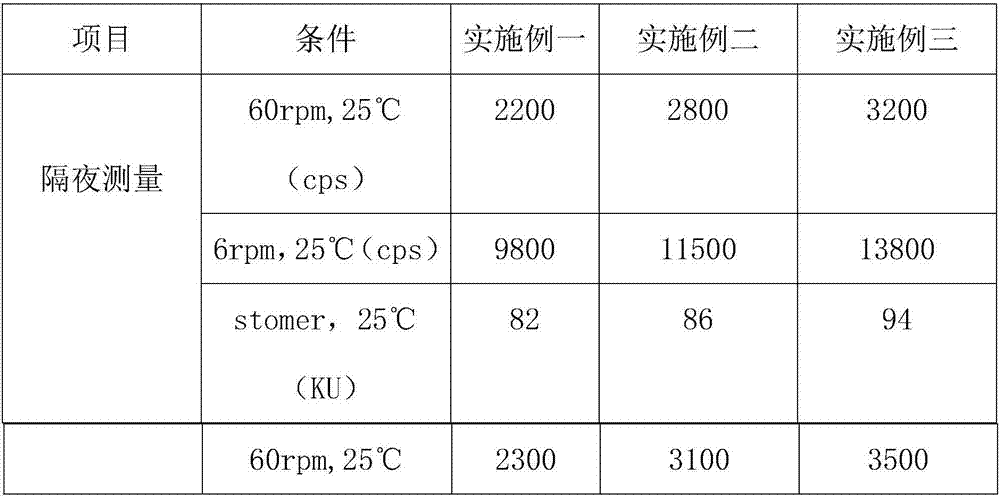

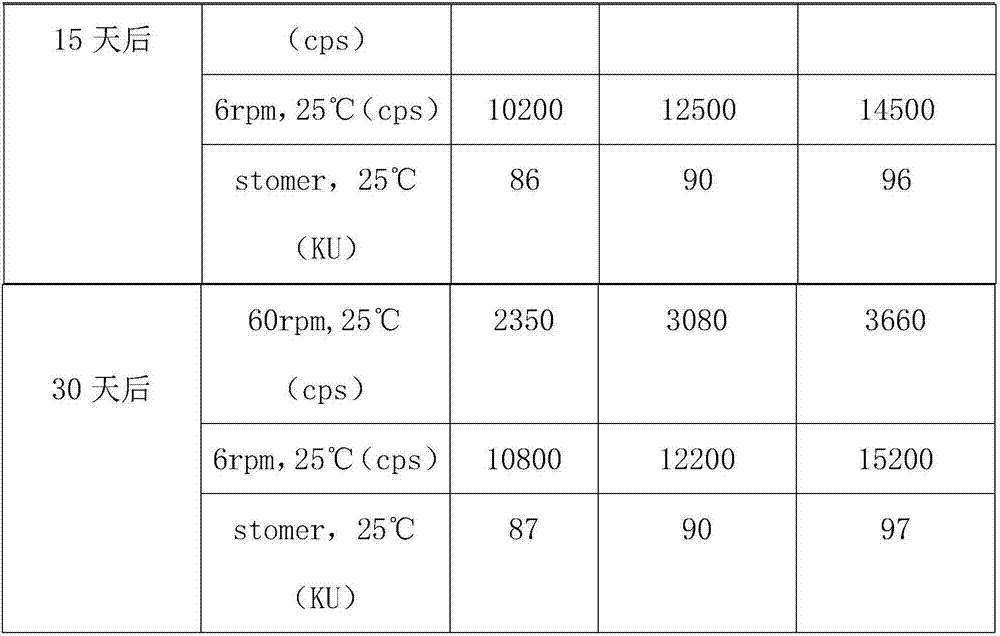

Examples

Embodiment 1

[0020] A modified general-purpose latex paint, which is configured from the following raw materials in parts by weight:

[0021] 12.5 parts by weight of base material; 92.25 parts by weight of pigment; 1.9 parts by weight of wetting and dispersing agent; 0.2 parts by weight of defoamer; 0.15 parts by weight of agent; 0.45 parts by weight of thickener; 100% of deionized water is supplemented, wherein, the thickener adopts ASE thickener, and the wetting and dispersing agent consists of 10% sodium hexametaphosphate solution of 1.5 parts by weight and 0.4 parts by weight Parts of sauerkraut polymer sodium salt mixed.

[0022] The base material is preferably styrene-acrylic emulsion.

[0023] The pigment is prepared from the following raw materials by weight: 2.5 parts by weight of anatase titanium dioxide; 3.75 parts by weight of rutile titanium dioxide; 15 parts by weight of lithopone; 5 parts by weight of 325 mesh talcum powder; 5 parts by weight of 800 mesh fine talcum powder ...

Embodiment 2

[0033] A modified general-purpose latex paint, which is configured from the following raw materials in parts by weight:

[0034] 12.5 parts by weight of base material; 92.25 parts by weight of pigment; 1.0 parts by weight of dispersant; 0.2 parts by weight of defoamer; Parts by weight; thickener 0.54 parts by weight; deionized water to make up 100%, wherein the thickener is a HASE thickener, the dispersant is a CPA type, and is matched with MC35, wherein MC35 is 0.2 parts by weight, a CPA type dispersant The weight part is 0.8.

[0035] The base material is preferably styrene-acrylic emulsion.

[0036] Described pigment is equipped with by the raw material of following weight ratio:

[0037] 2.5 parts by weight of anatase titanium dioxide; 3.75 parts by weight of rutile titanium dioxide; 15 parts by weight of lithopone; 5 parts by weight of 325 mesh talcum powder; 5 parts by weight of fine talcum powder of 800 mesh; 15 parts by weight of aluminum silicate; heavy calcium of ...

Embodiment 3

[0043] A modified general-purpose latex paint, which is configured from the following raw materials in parts by weight:

[0044] 12.5 parts by weight of base material; 92.25 parts by weight of pigment; 1.9 parts by weight of wetting and dispersing agent; 0.2 parts by weight of defoamer; 0.15 parts by weight of agent; 0.54 parts by weight of thickener; deionized water makes up 100%, wherein, the thickener adopts acrylic thickener, such as T33, and the dispersant adopts KPA type dispersant, and the parts by weight are 1.2, and collocation 0.7 PU40 in parts by weight is mixed.

[0045] The base material is preferably styrene-acrylic emulsion.

[0046] Described pigment is equipped with by the raw material of following weight ratio:

[0047] 2.5 parts by weight of anatase titanium dioxide; 3.75 parts by weight of rutile titanium dioxide; 15 parts by weight of lithopone; 5 parts by weight of 325 mesh talcum powder; 5 parts by weight of fine talcum powder of 800 mesh; 15 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com