Control method of washing machine and washing machine

A control method and washing machine technology, applied in the field of washing machines, can solve the problems affecting the spray effect, the execution of subsequent programs, the probability of hitting a bucket, etc., and achieve the effects of improving the spray effect, good spray effect, and good anti-splash effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

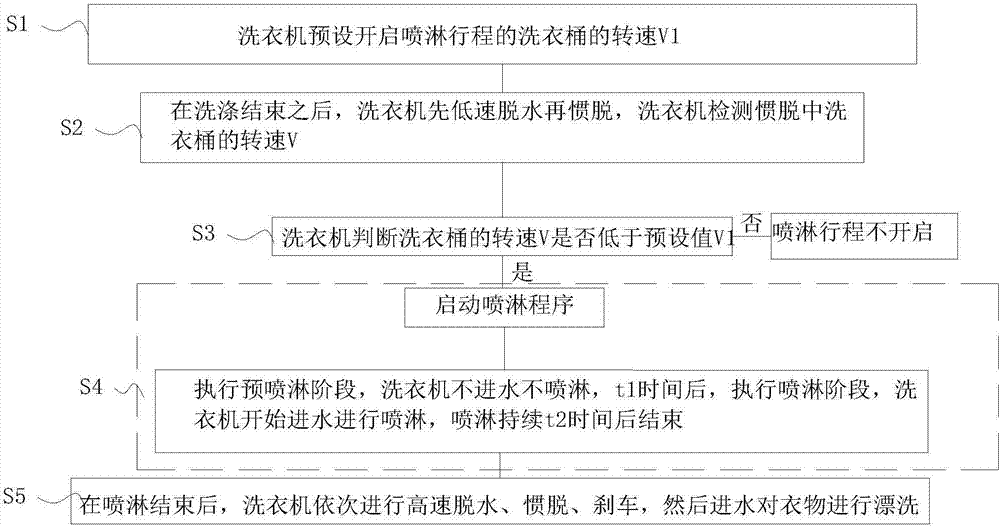

[0039] A control method for a washing machine. During the dehydration process before the rinsing program, the washing machine detects that the rotational speed of the laundry tub drops to a preset value V1 during the dehydration process, and controls to start the spraying program.

[0040] At present, the way for the washing machine to turn on the spray is to perform low-speed dehydration (about 30s), inertial dehydration (about 30s), and brake (about 5s) for a predetermined time after the washing is finished, so that the rotation speed of the washing tub is reduced to 0r / min, and then Turn on the spray, and as the rotation speed of the washing tub increases from 0 to 52r / min, spray while turning. After continuous spraying for 90s, perform high-speed dehydration (about 30s), inertial dehydration (about 40s), brake ( about 5s), the sprayed water is removed, and then the water is fed in, and subsequent rinsing is performed to rinse the clothes.

[0041] In the above process, on ...

Embodiment 2

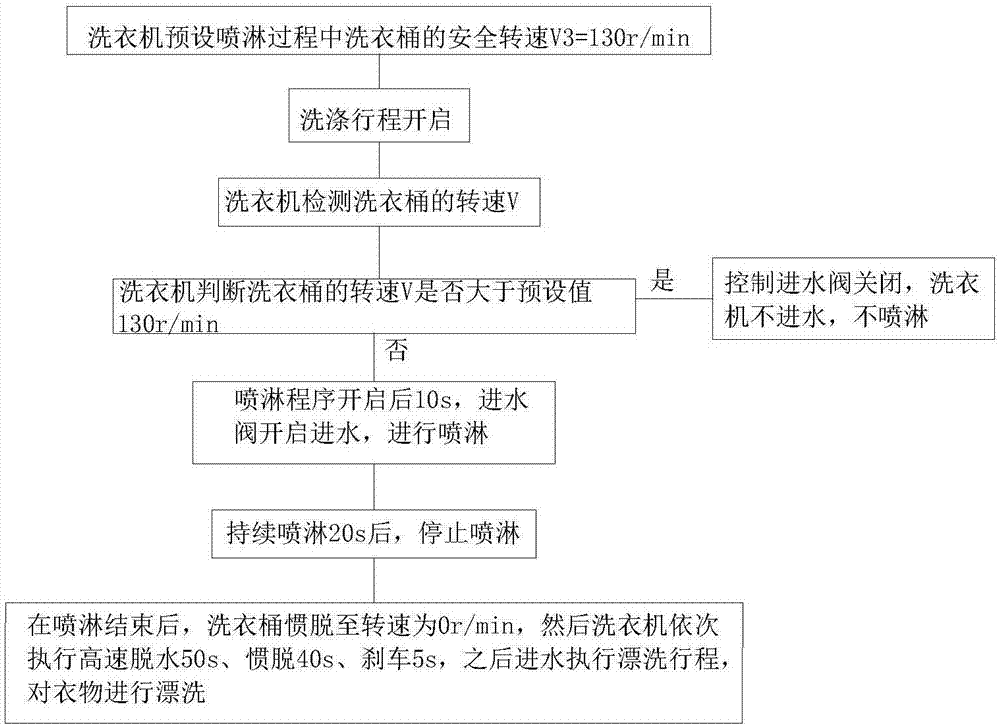

[0075] On the basis of Embodiment 1, the control method of this embodiment also includes preset the safe rotational speed V3 of the washing tub during the spraying process, V3>V1, the washing machine detects the rotational speed V of the washing tub during the spraying process, and judges the rotational speed of the washing tub Whether V is higher than V3, if yes, the spray program is turned on by mistake, the washing machine does not enter water and does not spray.

[0076] This process is for the protection of the washing machine. If the washing machine executes the wrong command, the spray program will be turned on by mistake. For example, it will be turned on when the washing tub is still at a high speed, which may cause danger. The safe speed is V3. After the spray program is turned on, the washing machine judges whether the speed of the washing tub is higher than V3. If it is, the washing machine does not enter water and does not spray.

[0077] Best, V3=130r / min.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com