Diesel engine after-treatment system capable of meeting National sixth-stage emission standard

A diesel engine and post-treatment technology, which is applied in exhaust gas treatment, electronic control of exhaust gas treatment devices, mechanical equipment, etc., can solve problems such as difficult conversion efficiency and low exhaust temperature of diesel engines, achieve reduced coupling calibration, and facilitate maintenance , Simple installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some parts related to the present invention are shown in the accompanying drawings but not the whole content. Unless otherwise defined, all technical and scientific terms used herein are related to the technical field of the present invention. The skilled person generally understands the same meaning. The terms used herein are for describing specific embodiments only, and are not intended to limit the present invention.

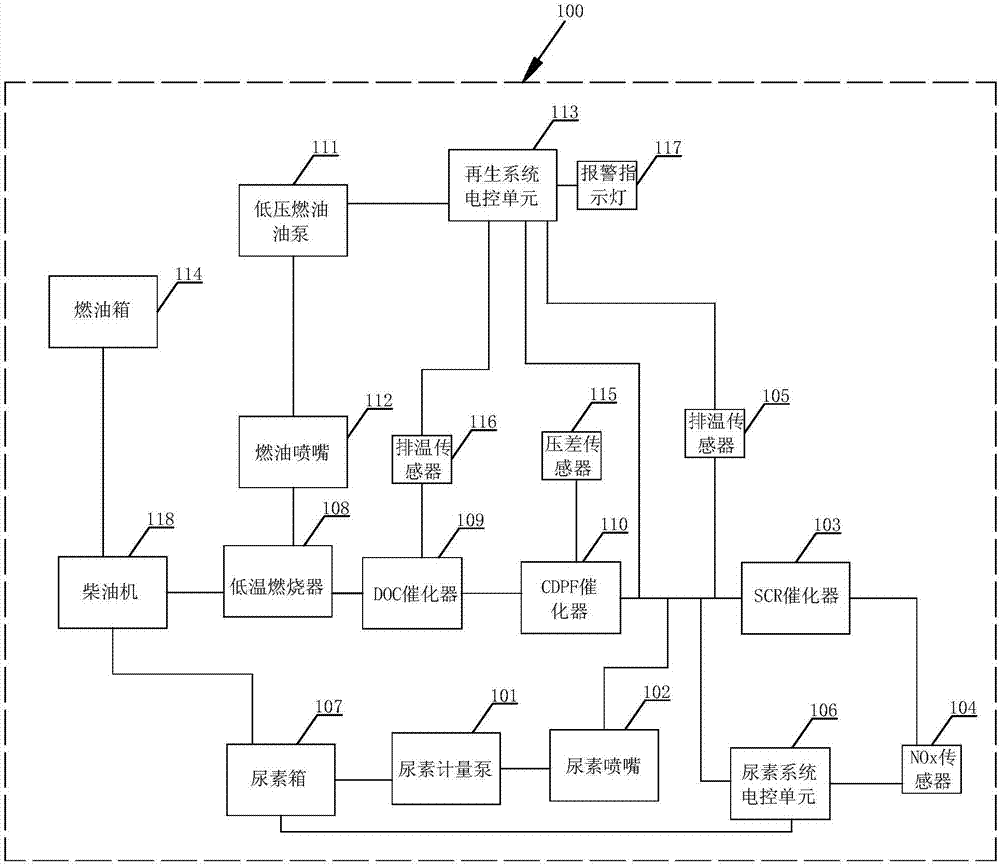

[0016] Please refer to figure 1 as shown, figure 1 Structural diagram of a diesel engine aftertreatment system that meets China VI emissions provided by the embodiment of the present invention.

[0017] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com