Non-contact length measuring device

A length measurement, non-contact technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as low accuracy, reduced measurable signal-to-noise ratio, and easy to cause errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

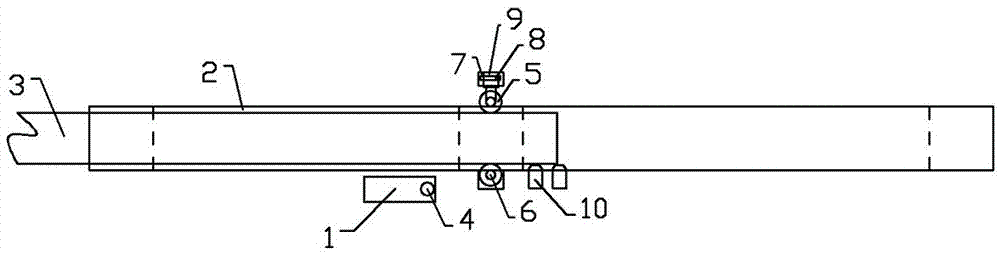

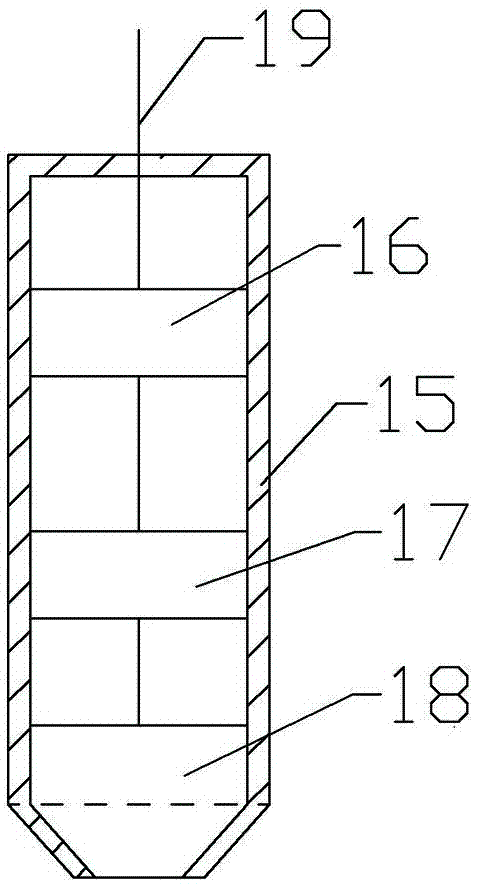

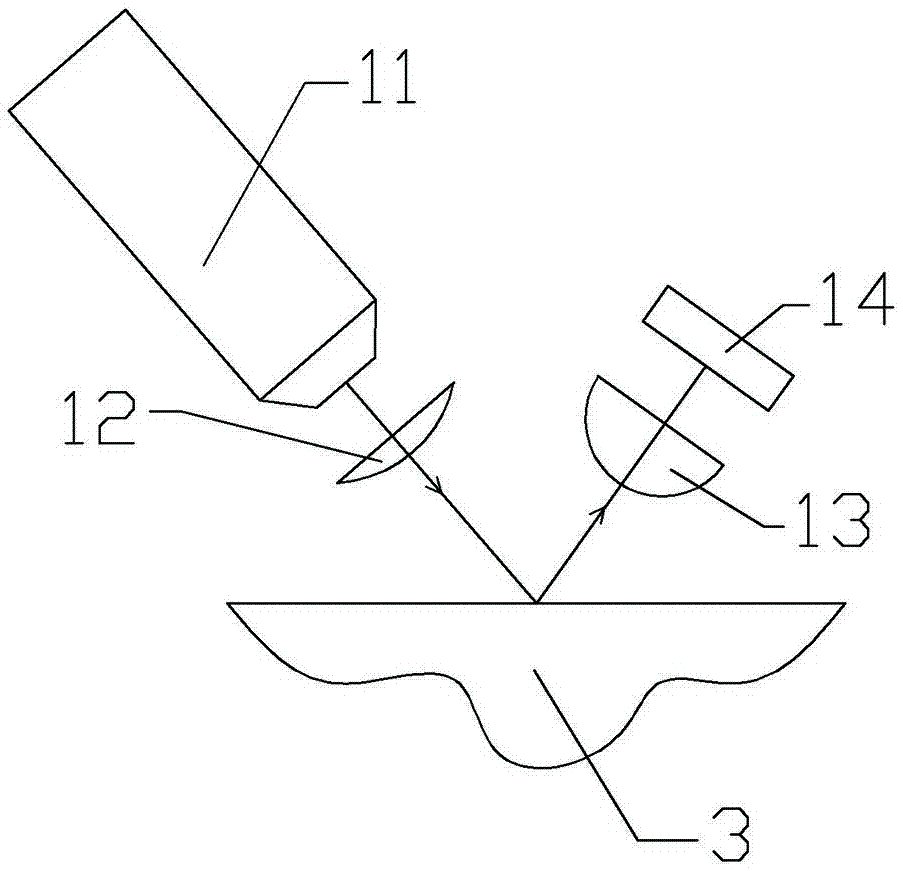

[0034] Such as Figure 1-4 The shown non-contact length measuring device includes a conveying device 2, a control device 1, a positioning device and two parallel non-contact length measuring sensors 10, wherein the conveying device 2 is a conveyor belt, the control device 1 includes a display, and the control device 1 also It is connected with a stabilized power supply and an audible and visual alarm device 4. The positioning device includes a fixed part on the same side as the non-contact length measurement sensor and an elastic part on the other side. Both the fixed part and the elastic part include an upward connecting rod 6, and the connecting rod 6 Rollers 5 are arranged horizontally near the upper end, and the object 3 to be measured is positioned by squeezing between the two rollers 5. The elastic part also includes an elastic device, which includes a column 7, and the upper end of the column 7 is fixed with a gas The spring 9, the free end of the piston of the gas spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com