Method for evaluating toxicity and biodegradability of chemical wastewater

A technology for chemical wastewater and evaluation methods, applied in the direction of testing water, material inspection products, etc., can solve the problems of inability to measure the toxicity of organic substances, inability to characterize the degree of toxicity of wastewater, and long detection period, achieving convenient and accurate determination and short determination time. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

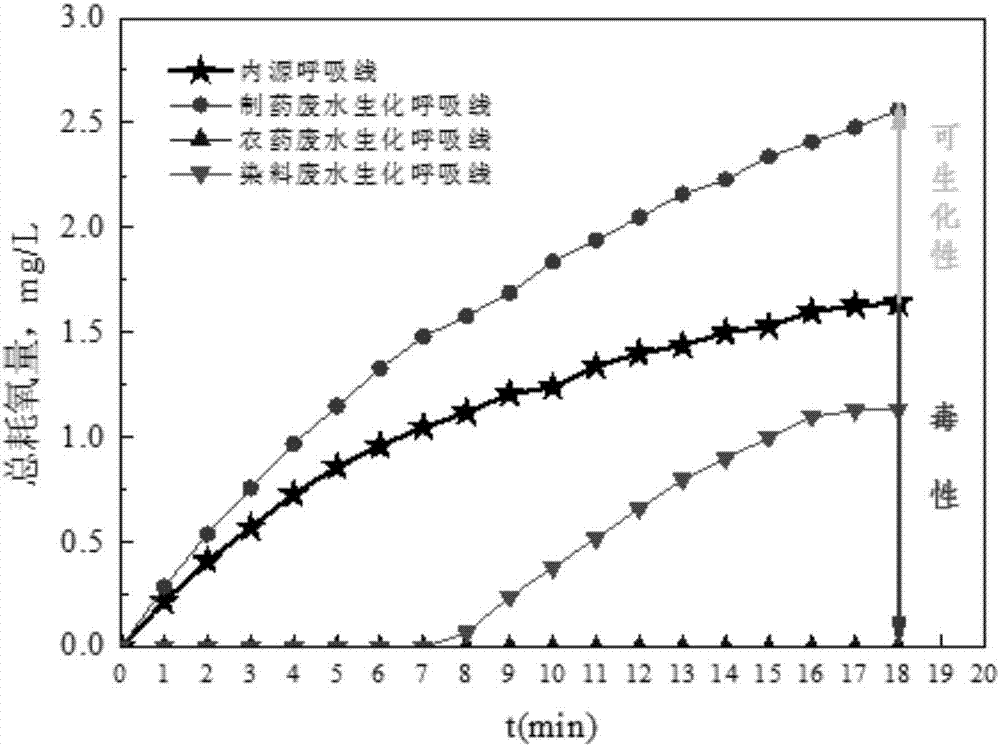

[0049] The effluent from the wastewater treatment station of a pharmaceutical factory in a chemical industry park, the effluent from the wastewater treatment station of a dye factory, and the effluent from a pesticide factory wastewater treatment station were selected for biodegradability and toxicity testing. The determination steps are as follows:

[0050] (1) pharmaceutical wastewater, dye wastewater, pesticide wastewater are diluted to the same CODcr, and the present embodiment is diluted to 200mg / L;

[0051] (2) Fully oxygenate the diluted water and the diluted pharmaceutical wastewater, dye wastewater, and pesticide wastewater at 20°C and adjust the pH to 7.5;

[0052] (3) Mix the above four kinds of water with the domesticated and cleaned sludge in equal proportions, and adjust the sludge concentration to 4g / L;

[0053] (4) Use the PF-8000 sludge respiration instrument produced by the U.S. RSA company with ISO standards to draw oxygen consumption curves for endogenous ...

Embodiment 2

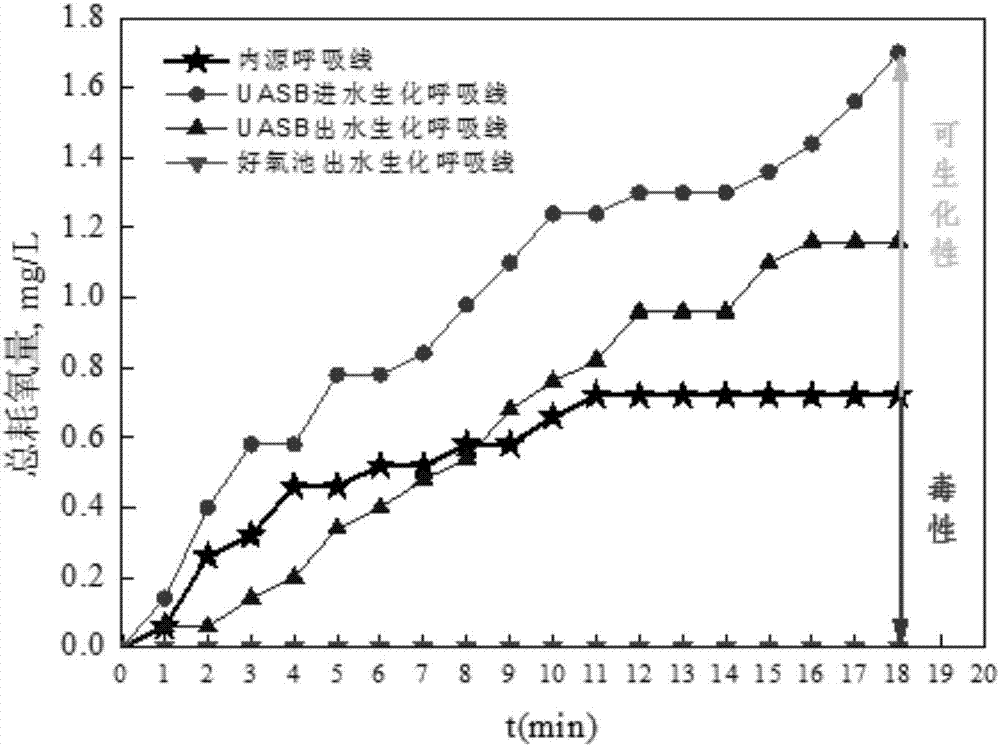

[0056] The waste water from different sections of the wastewater treatment station of a pesticide factory was selected for biodegradability and toxicity test. The process of this wastewater treatment station adopts the process of UASB section + O section. L, 298mg / L. The determination steps are as follows:

[0057] (1) Dilute the CODcr of UASB inlet and outlet water to 300mg / L respectively;

[0058] (2) Fully oxygenate the dilution water, UASB inlet and outlet water, and O-stage outlet water at 20°C and adjust the pH to 7.5;

[0059] (3) Mix the above four kinds of water with the domesticated and cleaned sludge in equal proportions, and adjust the sludge concentration to 4g / L;

[0060] (4) Use the PF-8000 sludge respiration instrument produced by the U.S. RSA company with ISO standards to draw oxygen consumption curves for endogenous respiration and biochemical respiration, and calculate the S in the reaction time. TOD value.

[0061] (5) if figure 2 As shown, UASB inlet...

Embodiment 3

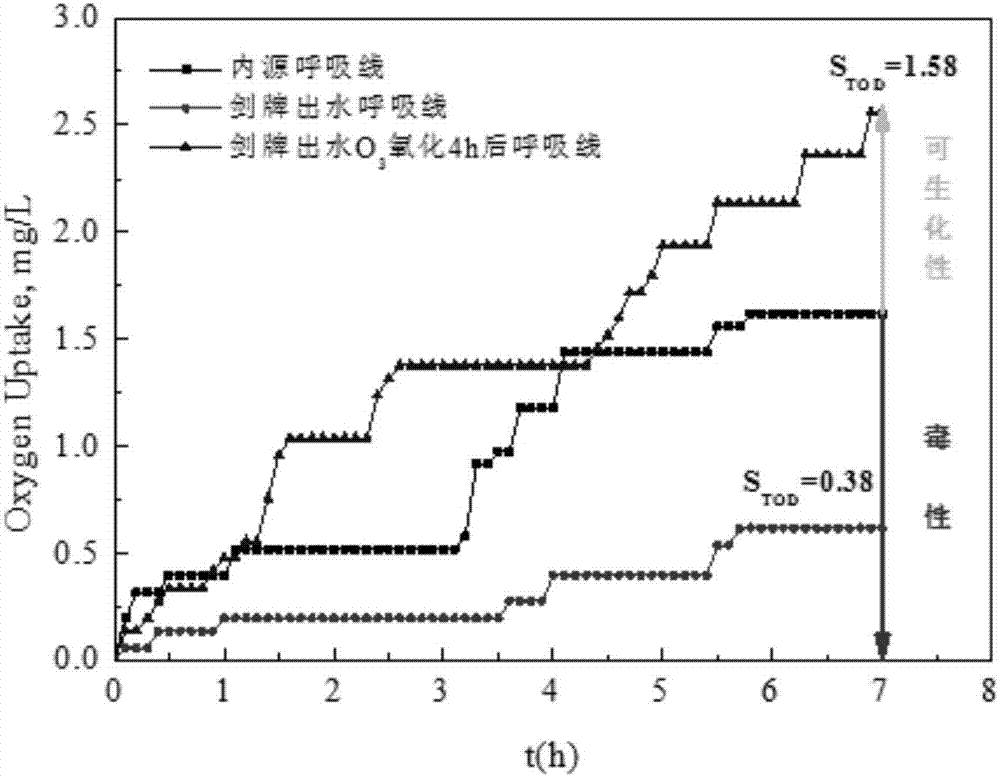

[0063] The effluent water from the wastewater treatment station of a pesticide factory in a chemical industry park is toxic and has a toxic effect on the operation of the takeover sewage plant. It needs advanced oxidation pretreatment before entering the takeover sewage plant. 3 The biochemical and toxicity degree of the oxidized effluent is identified, and the steps are as follows:

[0064] (1) the wastewater treatment station effluent, O 3 After oxidation, the effluent is fully oxygenated at 20°C and the pH is adjusted to 7.5;

[0065] (2) Mix the above two kinds of water with the domesticated and cleaned sludge in equal proportions, and adjust the sludge concentration to 4g / L;

[0066] (3) Use the PF-8000 sludge respiration instrument produced by the U.S. RSA company with ISO standards to draw oxygen consumption curves for endogenous respiration and biochemical respiration, and calculate the S in the reaction time. TOD value.

[0067] (5) if image 3 As shown, the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com