Full-color semiconductor light emitting micro display and manufacturing process thereof

A technology of micro-display and manufacturing process, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc. It can solve the incompatibility of red light-emitting devices, green light-emitting devices and blue light-emitting devices in the production process and cannot meet the requirements of full-color Display requirements, reduce the yield rate of finished products, etc., to achieve the effects of improved process compatibility, reduced costs, and convenient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

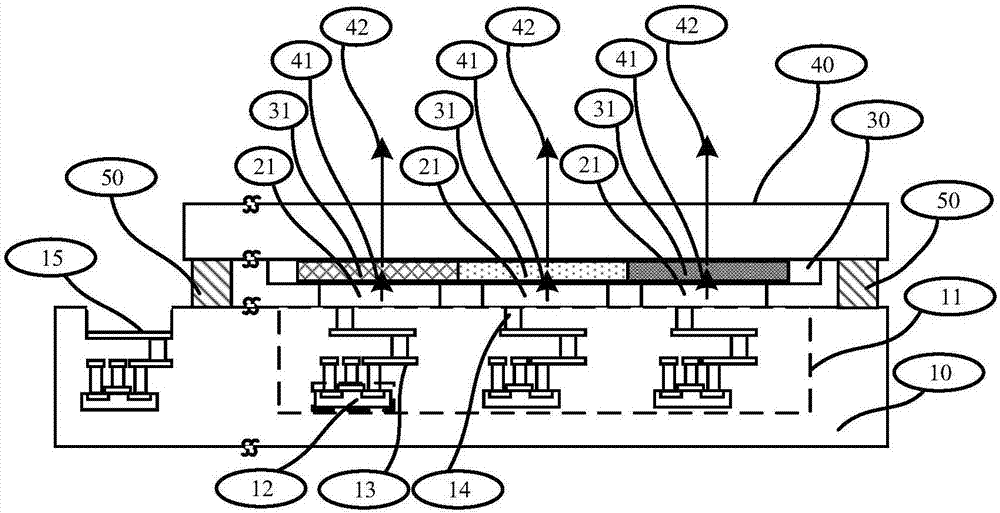

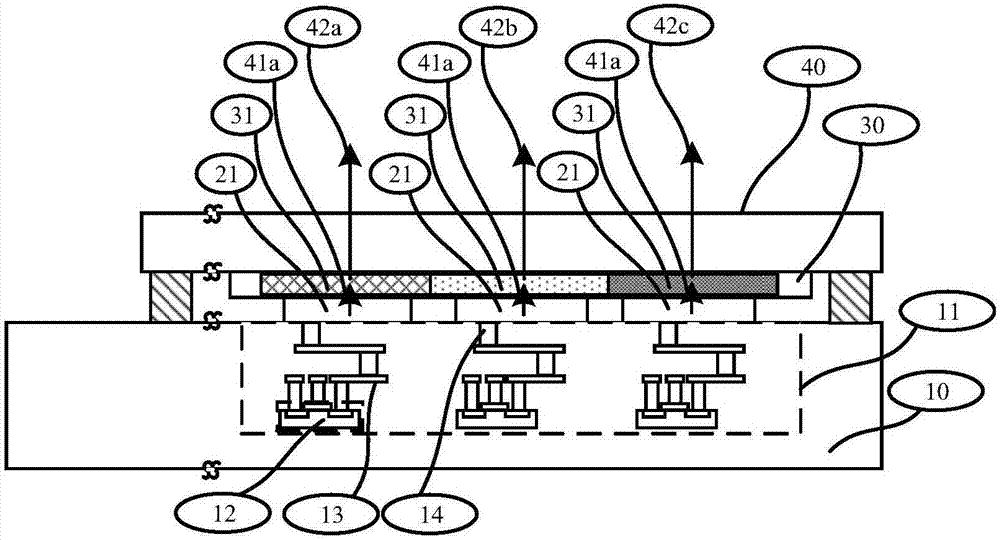

[0063] see figure 1 The full-color semiconductor light-emitting microdisplay is characterized in that it at least includes a silicon substrate 10, micro light-emitting diodes 21 arranged in an array, and a transparent substrate 40 with a color filter layer 30, and:

[0064] The silicon substrate includes a driving circuit 11, and the driving circuit 11 includes at least a metal-oxide semiconductor field effect transistor 12, a metal connection line 13, and a through hole 14. More specifically, the driving circuit 11 also includes an interface 15, which is used for external Bring in signals and power;

[0065] The micro light emitting diode 21 at least includes a first electrode 22, a multilayer non-organic compound 23 and a second electrode 24 (see Figure 8(a)-8(b) ), the non-organic compound 23 is composed of Ga, As, In, Al, Se, Zn, Si, P, N or C elements and can be doped; further, the non-organic compound is preferably GaAs, GaAsP, AlGaAs, AlGaInP , GaInN, AlGaP, AlGaN, G...

Embodiment 2

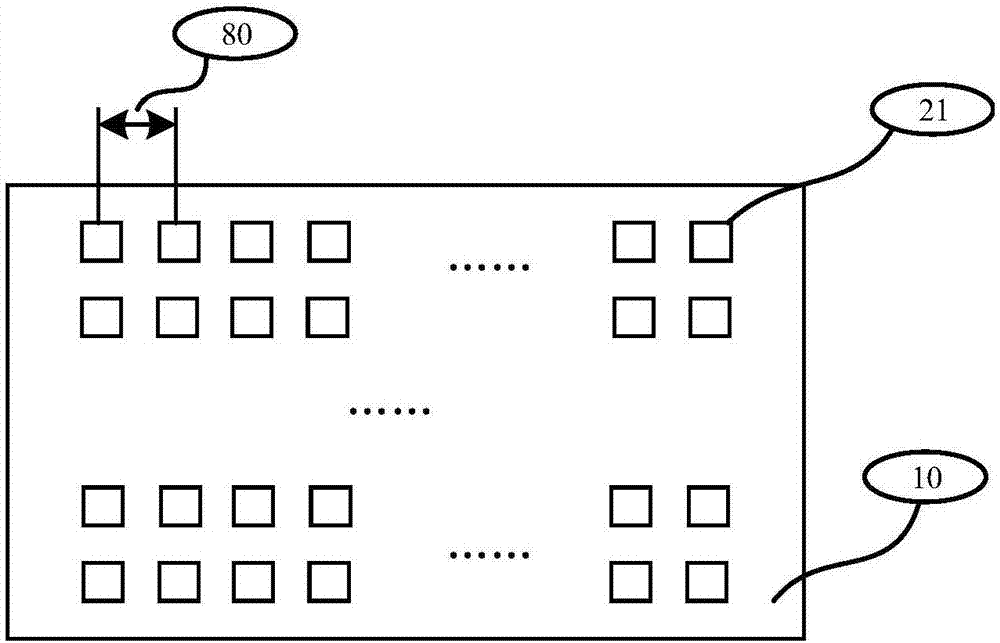

[0071] see figure 2 , this embodiment is basically the same as the first embodiment. Further, the center distance 80 between the micro-light emitting diodes 21 is not greater than 20 μm, preferably 5-10 μm in this embodiment, and the current of a single micro-light-emitting diode 21 is not higher than 30 μA. Embodiment preferred 1~5 μ A, thereby specified the pixel size size and the pixel current range of the full-color semiconductor light-emitting microdisplay of the present invention, and this is obviously smaller than the conventional display with glass as the substrate, making this embodiment very suitable for microdisplays .

Embodiment 3

[0073] This embodiment is basically the same as the first embodiment. Further, the color filter point 31 completely covers the micro-LED 21 in the vertical direction, and the distance between the center point of the color filter point 31 and the center point of the micro-LED 21 is not greater than 1 μm, In this embodiment, it is preferably 0.5 μm, so that the pixel pitch can be reduced and the pixel aperture ratio can be increased within an optional process deviation range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com