Grape canned preservative and preparation method thereof

A preservative and canning technology, applied in the field of canned grape preservatives and its preparation, can solve the problems of short storage time of canned grapes and prolonged storage time of canned grapes, and achieve the effects of inhibiting the growth of bacteria, improving antiseptic efficiency, and preventing fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

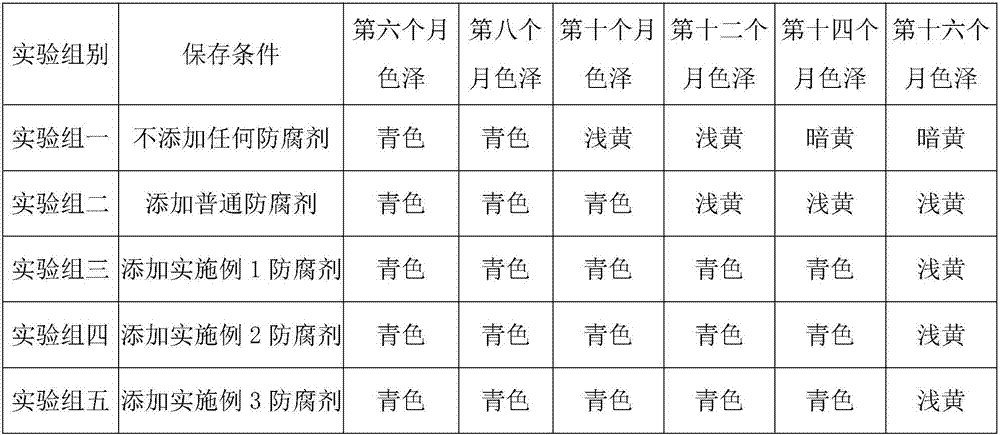

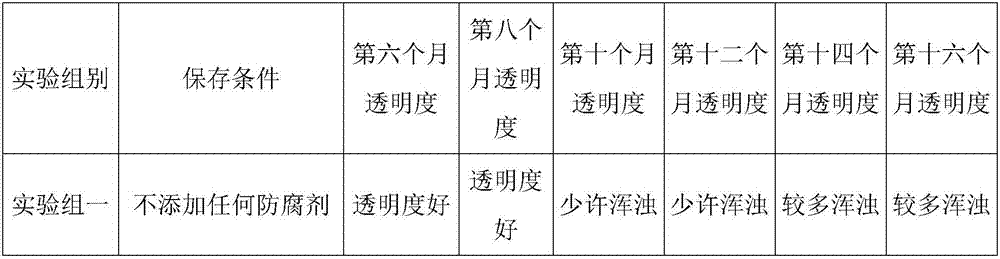

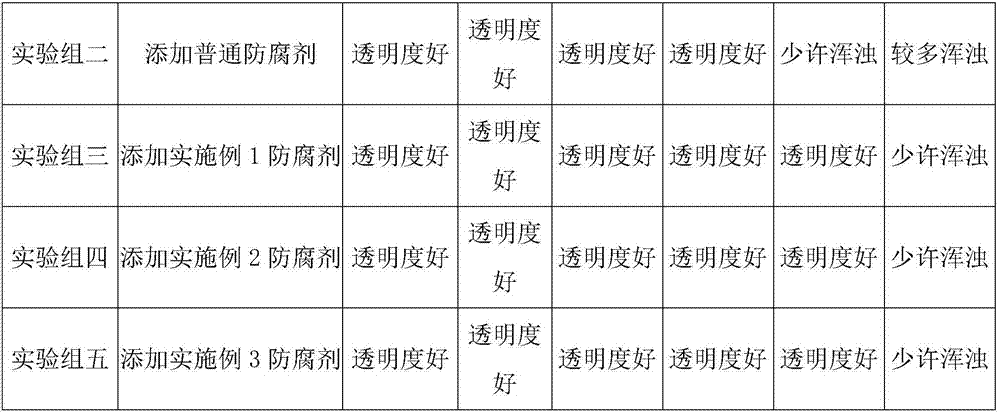

Examples

Embodiment 1

[0026] A kind of canned grape preservative, by weight percentage, its formula is as follows:

[0027] Natamycin 4%, polylysine 2%, potassium sorbate 0.3%, grape skin extract 2%, dehydroacetic acid 0.2%, tea polyphenols 1.5%, anthocyanins 0.8%, and the rest is water.

[0028] The preparation method of above-mentioned preservative comprises the following steps:

[0029] (1) Preparation of grape skin extract

[0030] Put the grape skins into the extraction tank, add an ethanol extraction solvent 1.5-2.5 times the weight of the grape skins, pressurize to 100-120Mpa and keep it for 20-25min, then release the pressure and filter, and put the filtrate in the refrigerator for the first refrigeration , the first refrigeration temperature is 0-3°C, the refrigeration time is 1-2h, the filtrate after the first refrigeration is centrifuged for the first time, the speed of the first centrifugation is 1500-1800r / min, the separation time is 10-20min, and the supernatant is collected Then ca...

Embodiment 2

[0034] A kind of canned grape preservative, by weight percentage, its formula is as follows:

[0035] Natamycin 6%, polylysine 2.5%, potassium sorbate 0.4%, grape skin extract 3%, dehydroacetic acid 0.3%, tea polyphenols 1.8%, anthocyanins 1.0%, and the rest is water.

[0036] The preparation method of above-mentioned preservative comprises the following steps:

[0037] (1) Preparation of grape skin extract

[0038] Put the grape skins into the extraction tank, add an ethanol extraction solvent 1.5-2.5 times the weight of the grape skins, pressurize to 100-120Mpa and keep it for 20-25min, then release the pressure and filter, and put the filtrate in the refrigerator for the first refrigeration , the first refrigeration temperature is 0-3°C, the refrigeration time is 1-2h, the filtrate after the first refrigeration is centrifuged for the first time, the speed of the first centrifugation is 1500-1800r / min, the separation time is 10-20min, and the supernatant is collected Then ...

Embodiment 3

[0042] A kind of canned grape preservative, by weight percentage, its formula is as follows:

[0043] Natamycin 8%, polylysine 3%, potassium sorbate 0.5%, grape skin extract 4%, dehydroacetic acid 0.5%, tea polyphenols 2.0%, anthocyanins 1.2%, and the rest is water.

[0044] The preparation method of above-mentioned preservative comprises the following steps:

[0045] (1) Preparation of grape skin extract

[0046] Put the grape skins into the extraction tank, add an ethanol extraction solvent 1.5-2.5 times the weight of the grape skins, pressurize to 100-120Mpa and keep it for 20-25min, then release the pressure and filter, and put the filtrate in the refrigerator for the first refrigeration , the first refrigeration temperature is 0-3°C, the refrigeration time is 1-2h, the filtrate after the first refrigeration is centrifuged for the first time, the speed of the first centrifugation is 1500-1800r / min, the separation time is 10-20min, and the supernatant is collected Then ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com