Precision cyclone milling machine tool for full-automatic machining of small modulus worm and method of precision cyclone milling machine

A whirlwind milling and fully automatic technology, applied in the direction of worms, mechanical equipment, components with teeth, etc., can solve problems such as difficult to exhaust, affect the quality of finished products, and complex structure of servo knife group, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

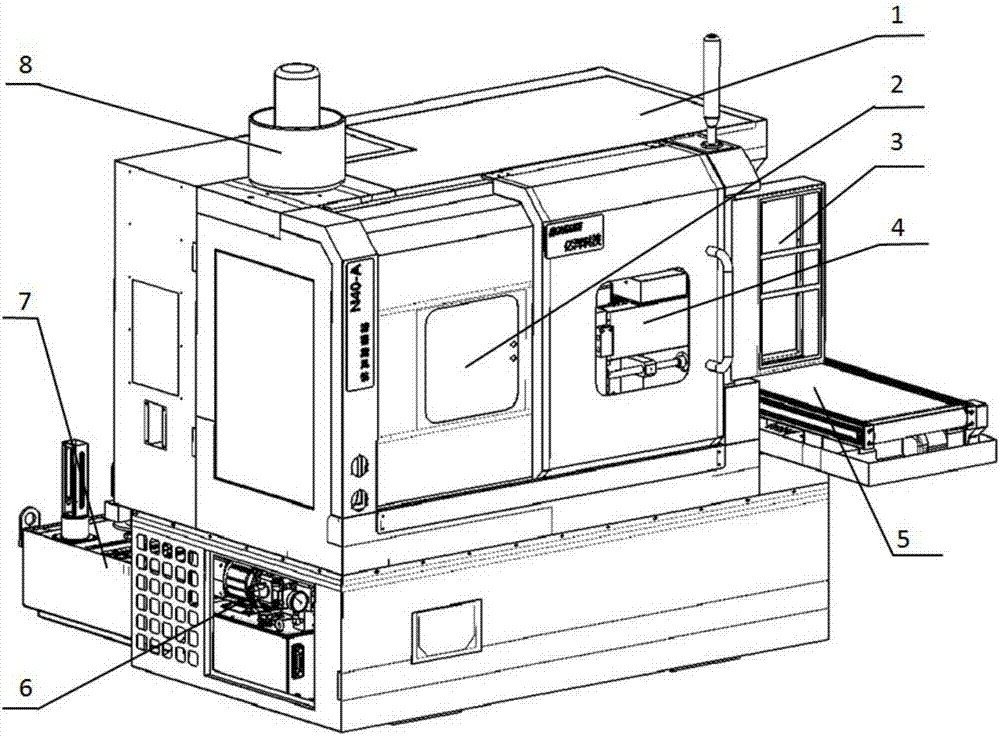

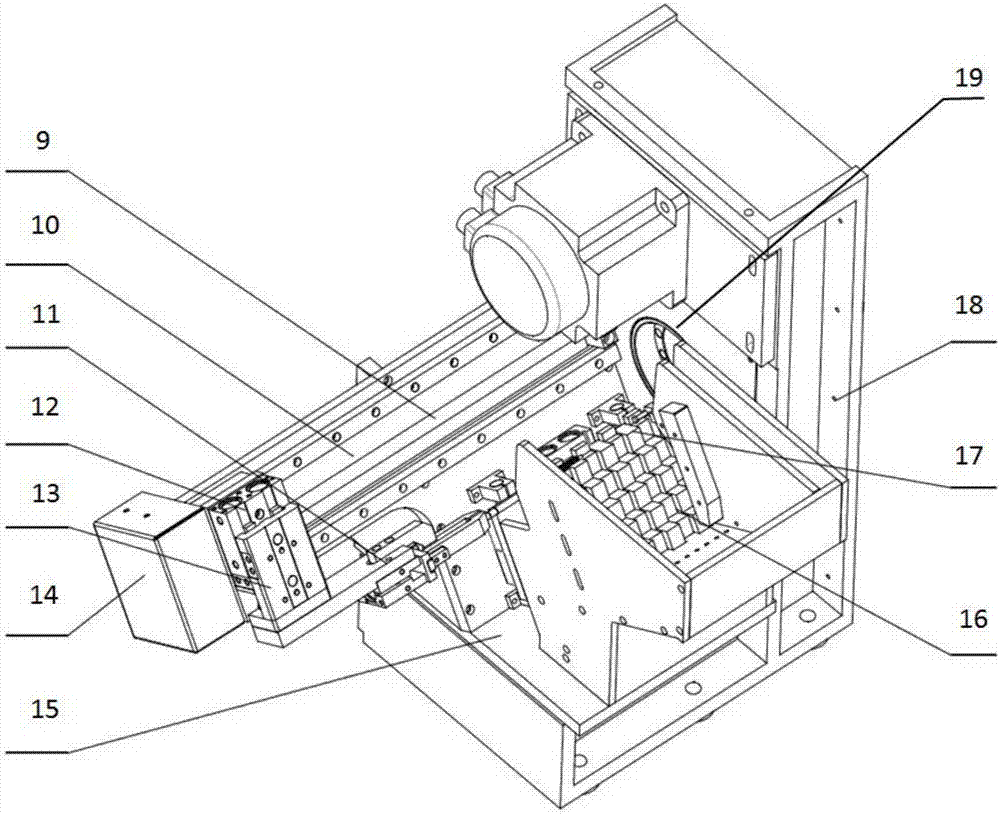

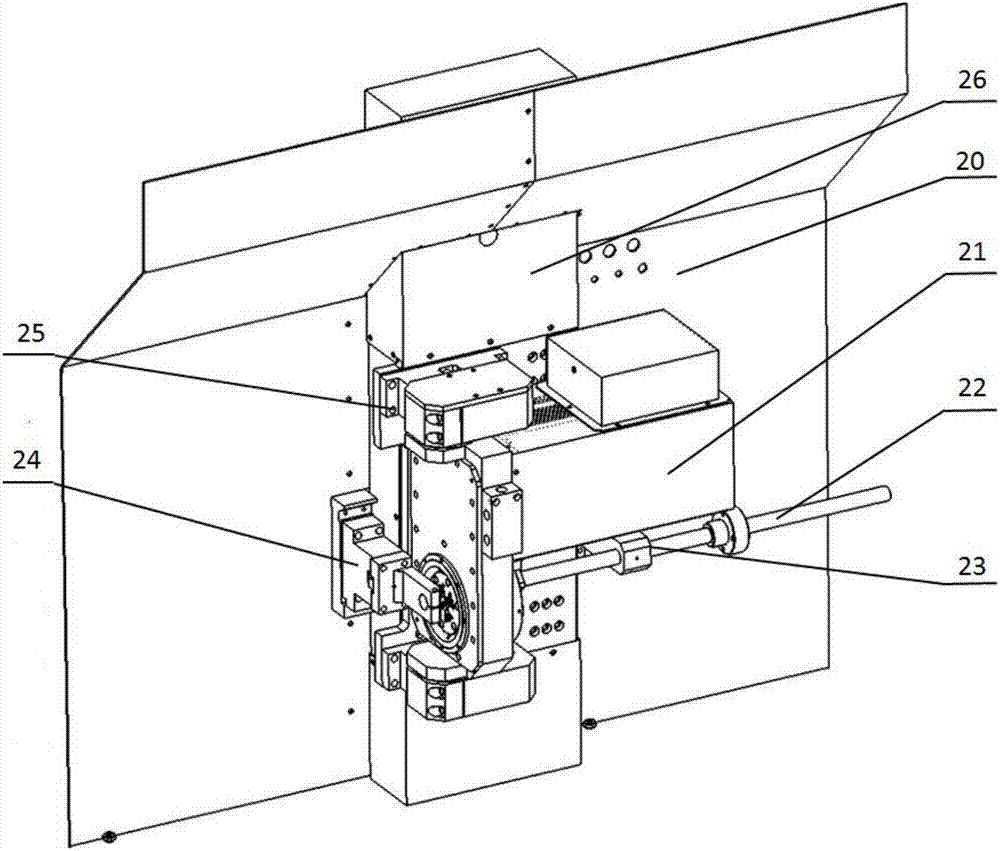

[0024] like figure 1 , 2 , 3, 4, and 5, a precision whirl milling machine tool for automatic machining of small modulus worms, including a machine bed mechanism 1, a feeding mechanism assembly 2, a digital control platform assembly 3, and a whirl milling head Mechanism assembly 4, feeding conveyor belt 5, hydraulic system mechanism 6, constant temperature filtration system 7, oil mist collection system 8, characterized in that the feeding mechanism assembly 2 includes guide rod 9, guide rail 10, mechanical clamp arm 11, horizontal Slider 12, vertical slider 13, motor 14, feeding trough base 15, feeding module moving plate 16, feeding module fixed plate 17, workpiece spindle 18, hydraulic rotary collet 19, cyclone milling head mechanism assembly 4 includes the carriage 20, the whirlwind milling head mechanism 21, the worm channel tube 22, the channel tube support seat 23, the center frame 24, the bracket 25, the column 26, the stepped slider 38, the upper guide rail 39, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com