Disk type anti-explosion and safe drying machine

A disc type, dryer technology, applied in chemical instruments and methods, dewatering/drying/concentrating sludge treatment, water/sludge/sewage treatment, etc. The problem of reducing the drying rate of mud, etc., achieves the effect of good dust blocking effect, improved safety, and good explosion-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

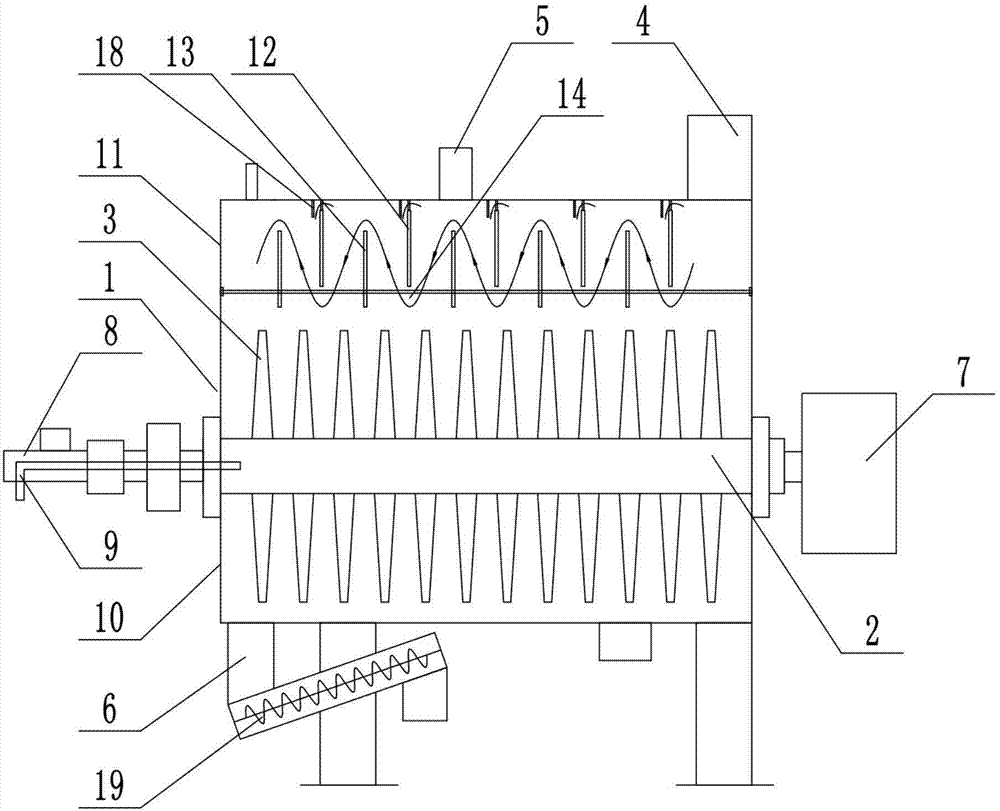

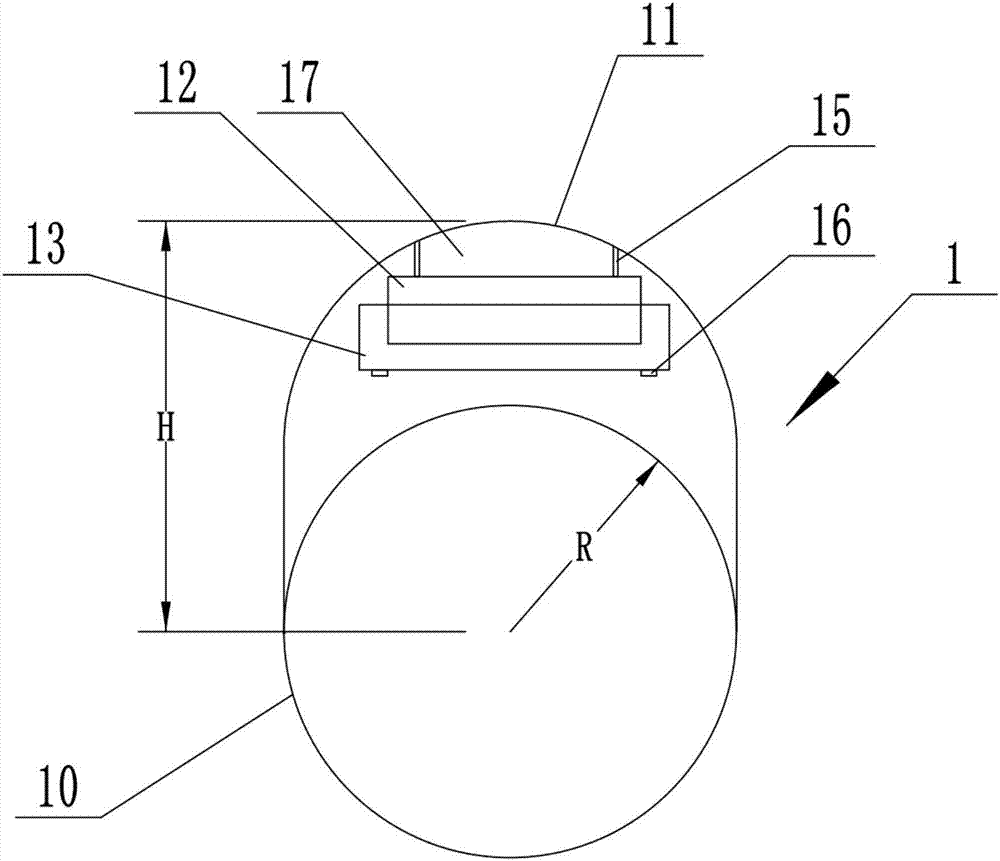

[0025] Such as figure 1 As shown, the disc-type explosion-proof safety drying machine of this embodiment includes a housing 1, a stirring shaft 2 is installed in the housing 1, and a disc piece 3 is installed on the stirring shaft 2, and the top of the housing 1 is arranged There are sludge inlet 4, steam outlet 5, and a dry sludge outlet 6 at the bottom. The stirring shaft 2 is driven by a motor 7 at one end. The stirring shaft 2 is a hollow structure, and one end is a hot steam inlet 8 and a condensed water outlet is inserted. Tube 9. The housing 1 includes a semi-cylinder 10 that is installed with the stirring shaft 2 and is coaxial with the stirring shaft 2, and a dome 11 extending upward from the upper side of the semi-cylinder 10. The cross-sectional structure of the housing 1 is: from the top of the dome 11 to the semi-cylindrical T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com