High temperature-resistant, hydrolysis-resistant and low-transformation ratio type TPU (thermoplastic polyurethane) for sealing ring of air cylinder and synthesizing method thereof

A synthesis method and hydrolysis-resistant technology, which is applied in TPU for hydrolysis-resistant, low-pressure variable cylinder sealing rings and synthesis, and high-temperature resistance fields. It can solve the problems of large environmental pollution, high comprehensive cost, and low production efficiency, and achieve the improvement of hydrolysis resistance. , Improved hydrolysis resistance, improved molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

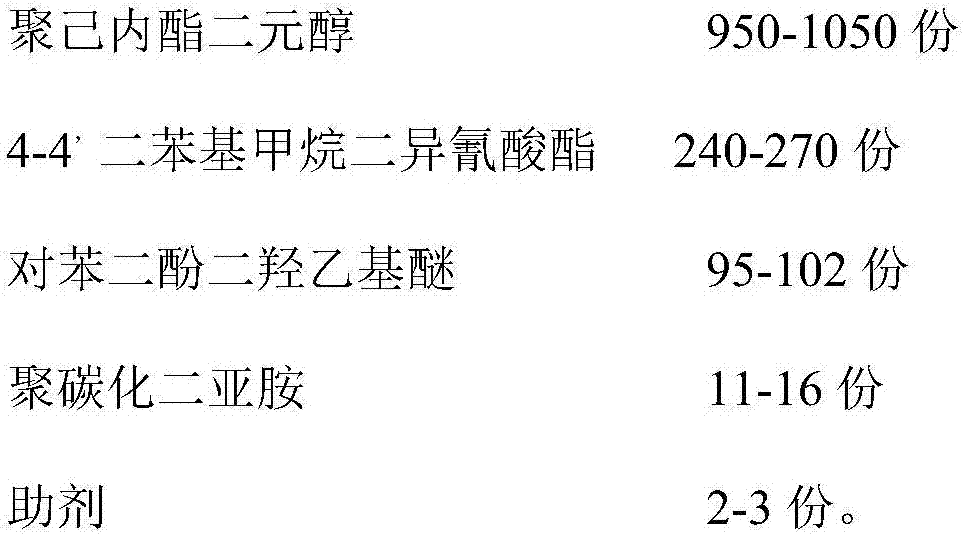

[0026] In the embodiment of the present invention, a high temperature resistant, hydrolysis resistant, low pressure variable cylinder seal ring TPU includes the following raw materials:

[0027]

[0028] A method for synthesizing TPU with high temperature resistance, hydrolysis resistance and low pressure variable cylinder sealing ring, comprising the following steps:

[0029] 1) Heat polycaprolactone diol to 80°C, then add antioxidant 1010, stir at a speed of 2800r / min, then add 4-4 diphenylmethane diisocyanate at 70°C, and then stir at 120r / min Continue to stir the mixture at a speed of 1 min. During the stirring process, ensure that the temperature of the mixture is between 85°C and 90°C. After reacting for 2 hours, the mixture material A is prepared and kept at 100°C for later use.

[0030] 2) Add polycarbodiimide and molten hydroquinone dihydroxyethyl ether to the mixture A, stir at a speed of 2800r / min under vacuum for 20 seconds, and pour it into a constant temperatu...

Embodiment 2

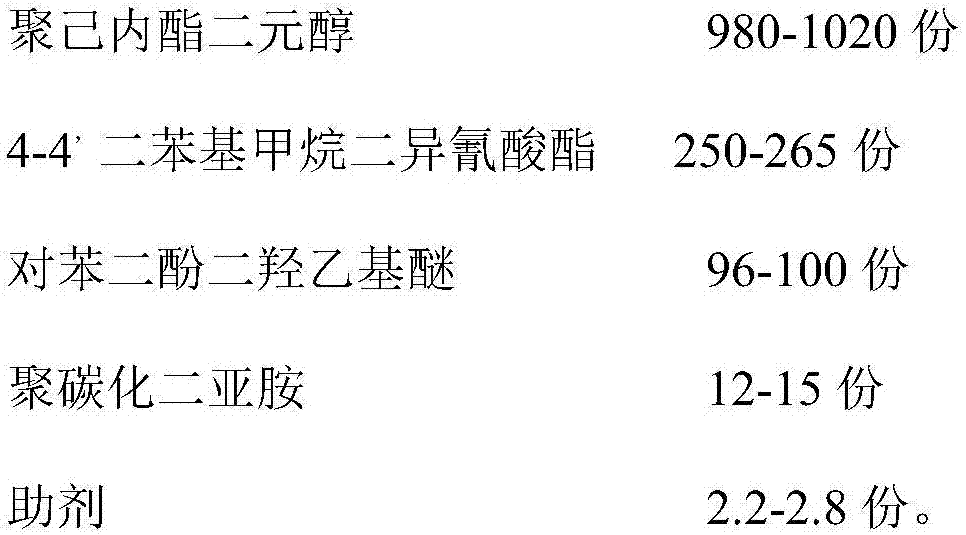

[0032] In the embodiment of the present invention, a high temperature resistant, hydrolysis resistant, low pressure variable cylinder seal ring TPU includes the following raw materials:

[0033]

[0034]

[0035] A method for synthesizing TPU with high temperature resistance, hydrolysis resistance and low pressure variable cylinder sealing ring, comprising the following steps:

[0036] 1) Heat polycaprolactone diol to 100°C, then add antioxidant 1010, stir at a speed of 2800r / min, then add 4-4'diphenylmethane diisocyanate at 80°C, and then stir at 120r / min Continue to stir the mixture at a speed of 1 min. During the stirring process, ensure that the temperature of the mixture is between 85°C and 90°C. After reacting for 2 hours, the mixed material A is prepared and kept at 120°C for later use.

[0037] 2) Add polycarbodiimide and molten hydroquinone bishydroxyethyl ether to the mixture A, stir at a speed of 2800r / min under vacuum for 40 seconds, and pour it into a consta...

Embodiment 3

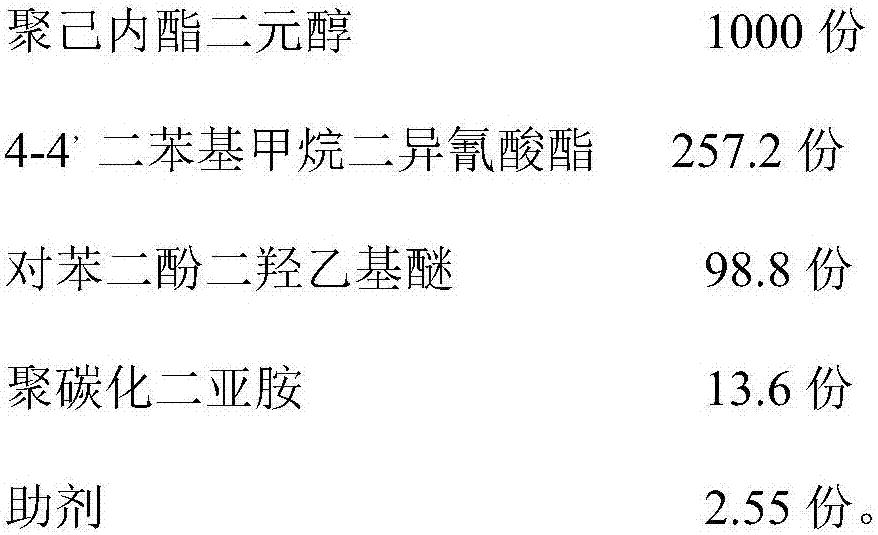

[0039] In the embodiment of the present invention, a high temperature resistant, hydrolysis resistant, low pressure variable cylinder seal ring TPU includes the following raw materials:

[0040]

[0041] A method for synthesizing TPU with high temperature resistance, hydrolysis resistance and low pressure variable cylinder sealing ring, comprising the following steps:

[0042] 1) Heat polycaprolactone diol to 85°C, then add antioxidant 1010, stir at a speed of 2800r / min, then add 4-4'diphenylmethane diisocyanate at 75°C, and then stir at 120r / min Continue to stir the mixture at a speed of 1 min. During the stirring process, ensure that the temperature of the mixture is between 85°C and 90°C. After reacting for 2 hours, the mixture material A is prepared and kept at 105°C for later use.

[0043] 2) Add polycarbodiimide and molten hydroquinone dihydroxyethyl ether to the mixture A, stir at a speed of 2800r / min under vacuum for 25 seconds, and pour it into a constant temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com