Polyphenyl ether resin packaging method

A technology of polyphenylene ether resin and packaging method, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., which can solve the problems of color tone change and achieve the effect of inhibiting color tone change and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092]As the dryer, the following 10-liter jacketed SUS dryer was used: a 10-liter conical belt dryer (RM-10D manufactured by Okawara Seisakusho Co., Ltd.) was used, and a discharge valve for sampling was installed at the bottom of the dryer. A temperature adjustment device is installed on the side of the dryer, a raw material input port and a nitrogen inlet are installed on the upper part of the dryer, and a bag filter is installed in the exhaust line. An oxygen concentration meter was installed at the gas outlet of the dryer.

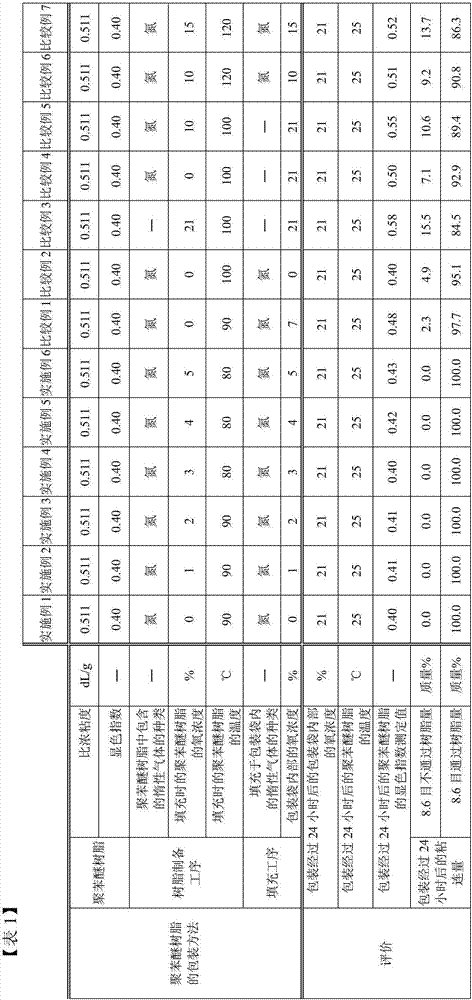

[0093] Using a part of polyphenylene ether resin (manufactured by Asahi Kasei Chemical Co., Ltd., S201A), measurement was performed according to the method of the above "(1) Reduced viscosity". As a result, the reduced viscosity of the polyphenylene ether resin was 0.511 dL / g. Similarly, the measurement was performed according to the method of "(2) color rendering index" above, and the color rendering index of the polyphenylene ether resin was 0.40. ...

Embodiment 2

[0099] The polyphenylene ether resin was packaged in the same manner as in Example 1, except that the oxygen concentration of the dryer exhaust gas was adjusted to 1%, and the oxygen concentration inside the packaging bag immediately before packaging was adjusted to 1%. The details and results of Example 2 are shown in Table 1.

Embodiment 3

[0101] The polyphenylene ether resin was packaged in the same manner as in Example 1, except that the oxygen concentration of the dryer exhaust gas was adjusted to 2%, and the oxygen concentration inside the packaging bag immediately before packaging was adjusted to 2%. The details and results of Example 3 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com