Decorative sheet and decorative member provided with decorative sheet

A decorative sheet and decorative layer technology, applied to decorations, crafts for producing decorative surface effects, decorative art, etc., can solve problems such as temperature rise and warping inside buildings, and achieve excellent heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

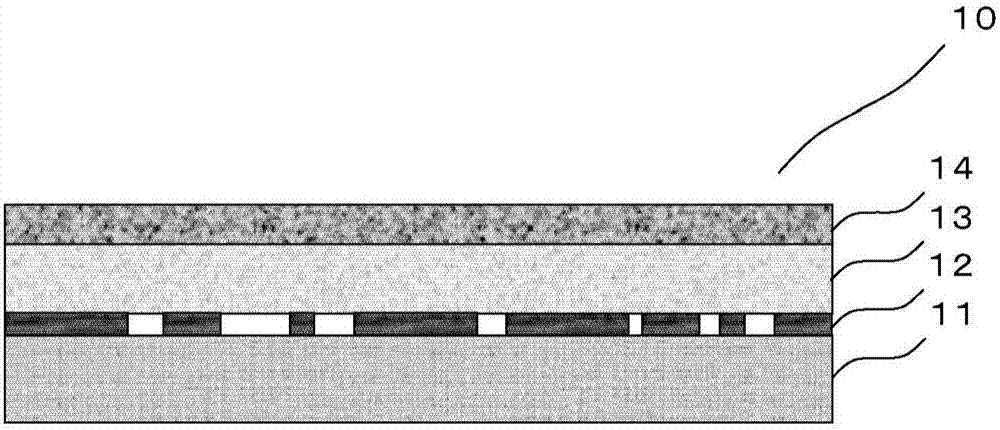

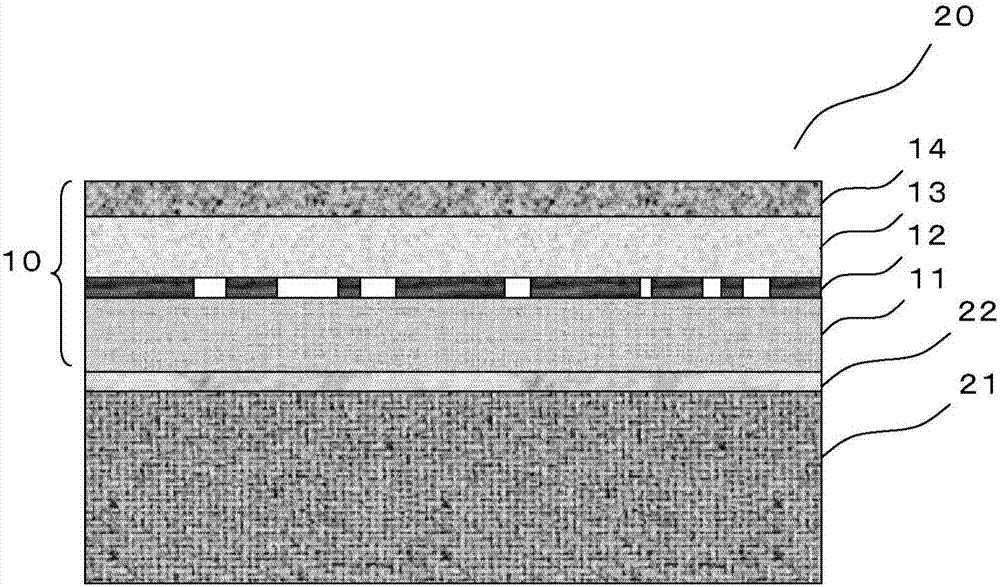

[0141] A polypropylene resin sheet (white coloring resin sheet, thickness: 60 μm, containing 0.01 parts by mass of carbon black as a pigment with respect to 100 parts by mass of polypropylene resin, which has been subjected to double-sided corona discharge treatment, is combined with titanium dioxide to obtain 10 parts by mass) as a substrate sheet, one surface of the substrate sheet is coated with a printing ink by a gravure printing method, and the printing ink uses a two-liquid curing type acrylic-urethane resin as a binding agent, and contains a solid content A composite oxide (pigment A, a composite oxide containing manganese, calcium and titanium, "MPT-370 (trade name)", manufactured by Ishihara Sangyo Co., Ltd.) with a wood grain of 70% by mass as a reference The decorative layer (thickness: 1 μm) was coated with a two-component curable urethane-nitrocellulose hybrid resin composition on the other side to form a backside primer layer (thickness: 2 μm). Apply a transpare...

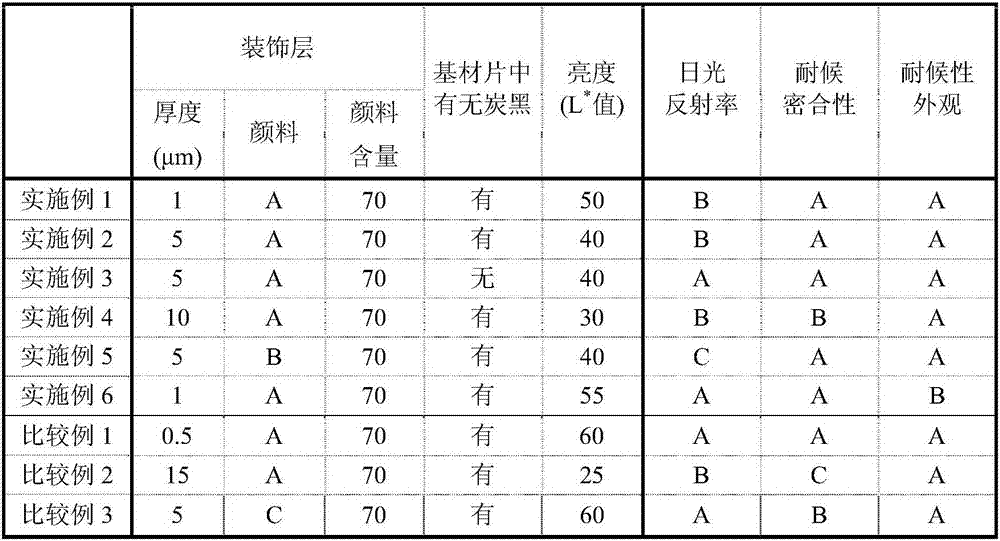

Embodiment 2~5 comparative example 1~3

[0144] In Example 1, the thickness of the decorative layer, the brightness, the type and content (%, solid content basis) of the composite oxide contained in the decorative layer were changed as described in Table 1, and the substrate sheet was changed. In Example 1, the decorative sheets of Examples 2-5 and Comparative Examples 1-3 were produced in the same manner. The above evaluation was performed on the obtained decorative sheet, and the evaluation results are shown in Table 1.

Embodiment 6

[0146] In Example 1, the decorative sheet and the decorative member were produced in the same manner as in Example 1, except that the amount of titanium dioxide in the double-sided corona discharge-treated polypropylene resin sheet was increased to 30 parts by mass of the pigment. The above evaluation was performed on the obtained decorative sheet, and the evaluation results are shown in Table 1.

[0147] 【Table 1】

[0148]

[0149]Note) Pigment A: Composite oxide containing calcium, titanium, and manganese ("MPT-370 (trade name)", manufactured by Ishihara Sangyo Co., Ltd.)

[0150] Pigment B: Composite oxide containing bismuth element and manganese element ("Black 6301 (trade name)", manufactured by ASAHI KASEIKOGYO CO., LTD.)

[0151] Pigment C: perylene black ("NBD-0744 (trade name)", manufactured by NIKKO BICS CO., LTD.)

[0152] It was confirmed that the decorative sheet of the present invention has a calm color tone (brightness is preferably 55 or less) aesthetics, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com