Method for producing sintered material from inorganic raw materials

A technology of sintered materials and mineral raw materials, applied in the field of producing cement clinker and mineral raw materials to produce sintered materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

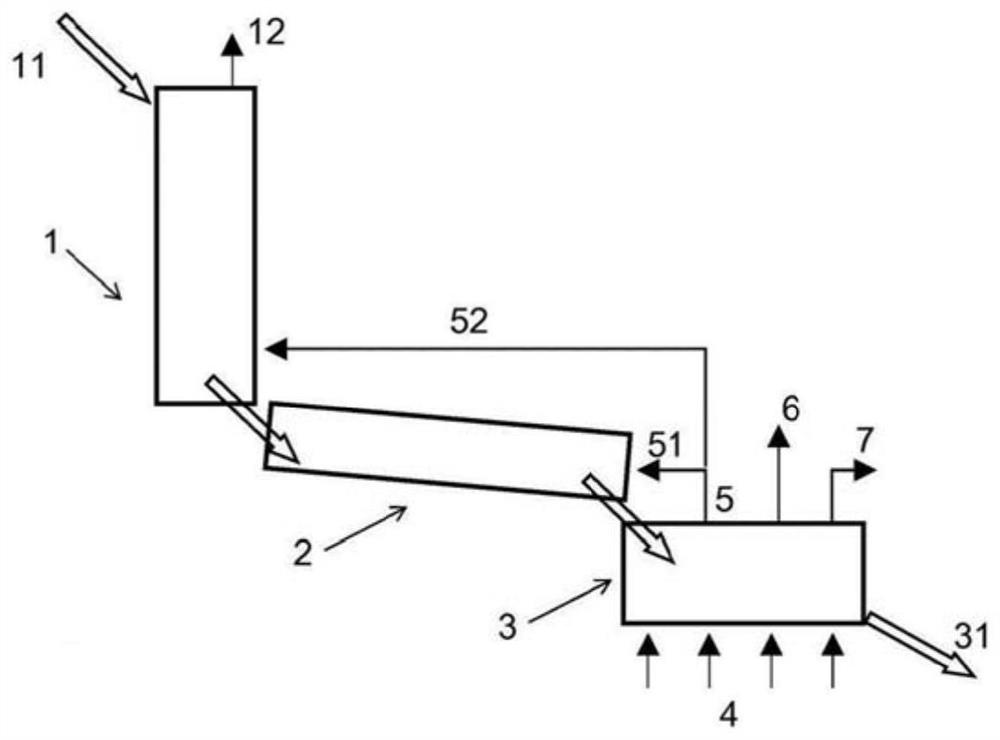

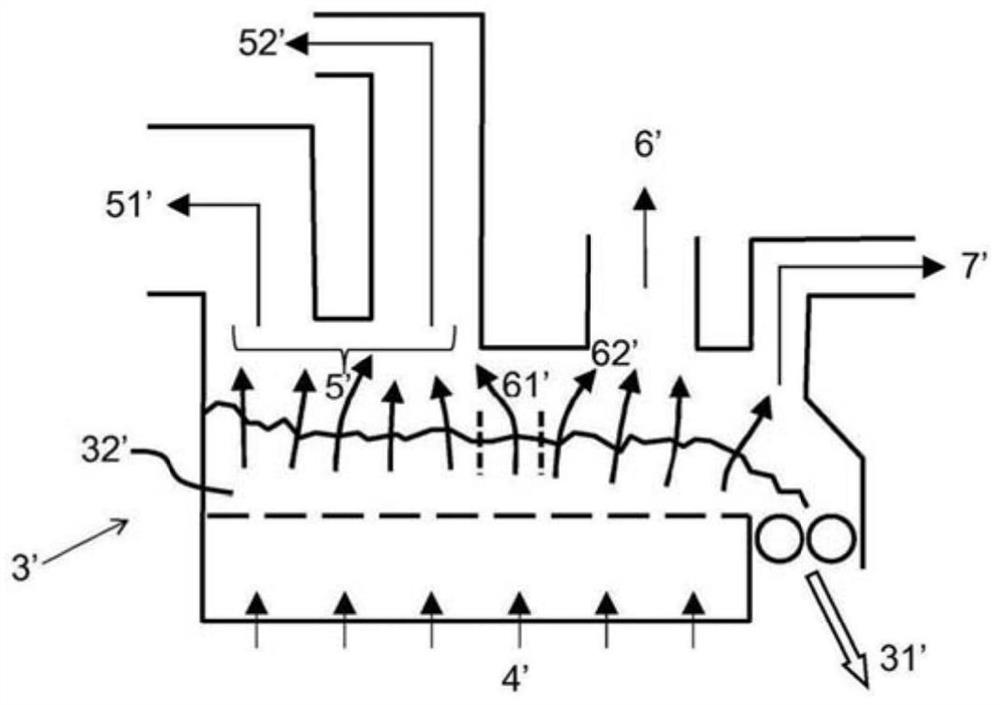

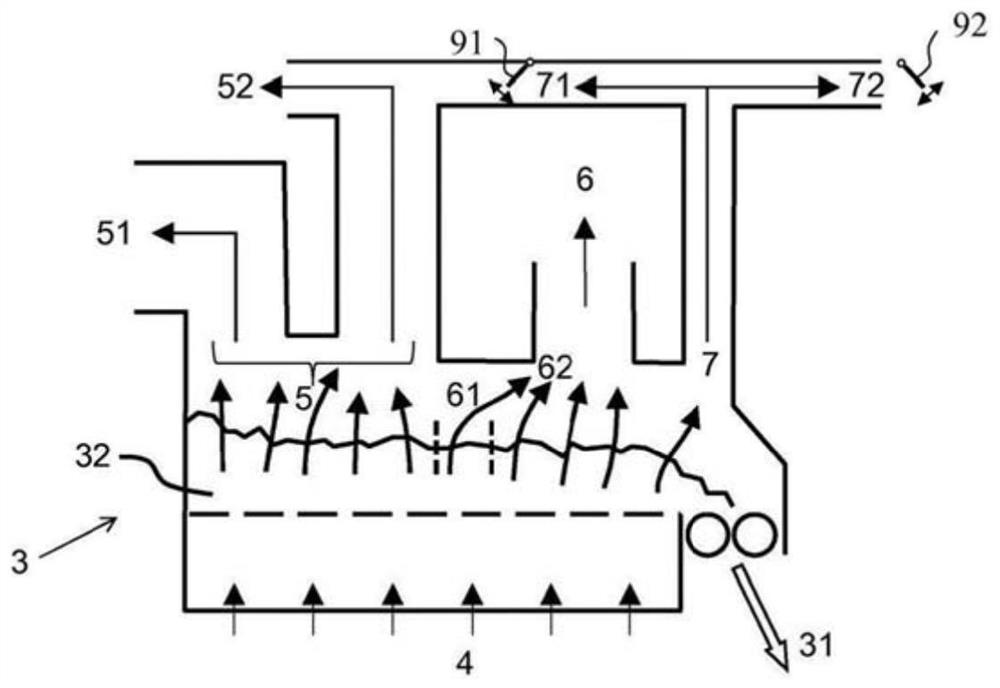

Method used

Image

Examples

example 1

[0052] Considering a cement plant combustion plant that consumes 2955kJ of combustible energy per kg of clinker, its cooler receives 1.837Nm for each kg of clinker to be cooled 3 Air. yields 0.909Nm 3 Combustion air, respectively 0.335Nm at 1160°C 3 0.574Nm of secondary air at 830°C 3 of three times the air. The volume of unused air is 0.928Nm 3 , the temperature is 223°C.

[0053] In order to recover unused heat and convert it into electricity using water / steam boiler, the unused air is divided into two streams, namely 0.664Nm at 260°C 3 middle flow and 0.264Nm at 130°C 3 For the discarded exhaust stream, increasing the temperature enables a consistently better conversion output of the intermediate stream. In this connection, for a plant producing 3000 t / d of clinker, 0.77 MW can be produced, which corresponds to a yield of 17.1%.

[0054] According to the invention, the exhaust gas flow (ie the third air fraction) is directed towards the tertiary air and the replacem...

example 2

[0056] For the same device described in Example 1, the organic Rankine cycle was used to generate electricity. Divide unused air into two streams, namely 0.729Nm at 250°C 3 middle flow and 0.199Nm at 123°C 3 of the discarded exhaust stream. In this connection, for a plant producing 3000 t / d of clinker, 0.52 MW can be produced, which corresponds to a yield of 15.2%.

[0057]According to one embodiment of the present invention, a part of the exhaust gas flow (i.e. the third air portion) is directed to the tertiary air, and the replaced tertiary air is mixed with the intermediate flow (i.e. the second air portion): put 0.115Nm 3 redirected, while 0.084Nm 3 is deprecated. The drop in combustion air temperature causes an increase in heat consumption, which reaches 3104 kJ per kg of clinker. Considering the corresponding increase in the demand for combustion air, there is 0.818Nm at 350°C 3 middle flow. For the 3000t / d plant already mentioned, 1.46MW can be produced, which co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com