Organic solid treatment system and method

An organic solid and organic technology, applied in the field of systems dealing with organic solids, can solve problems that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

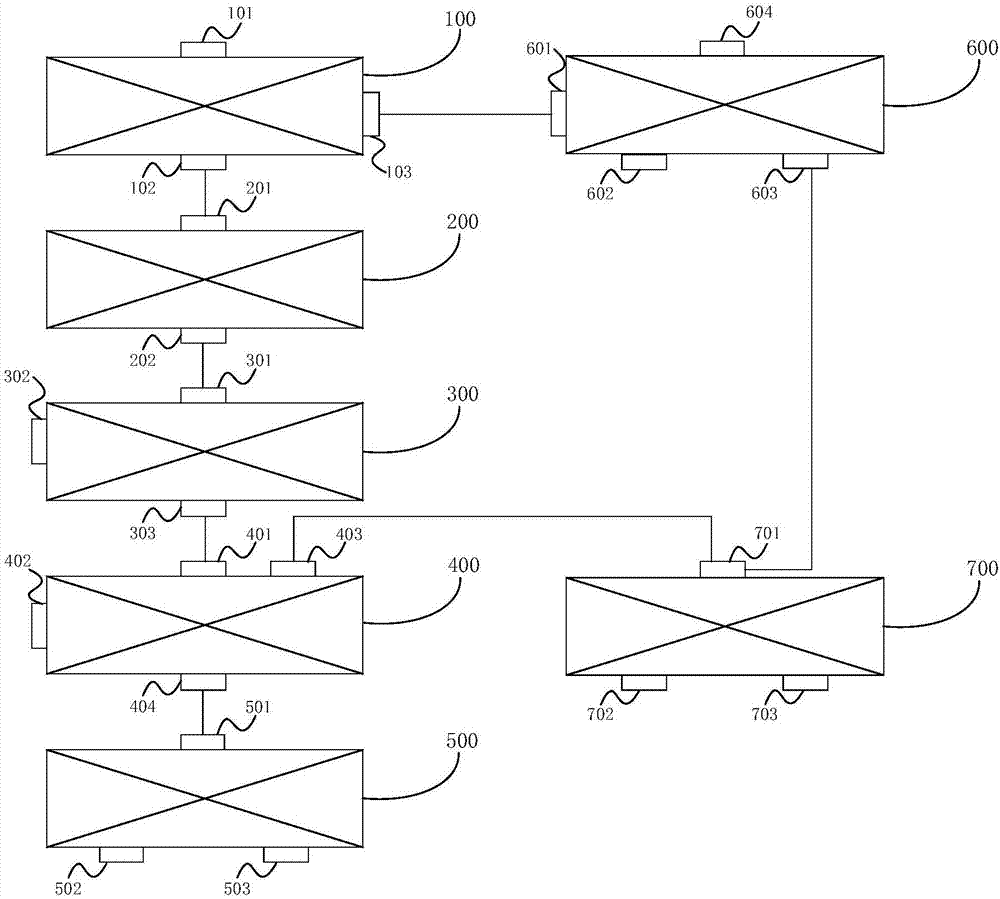

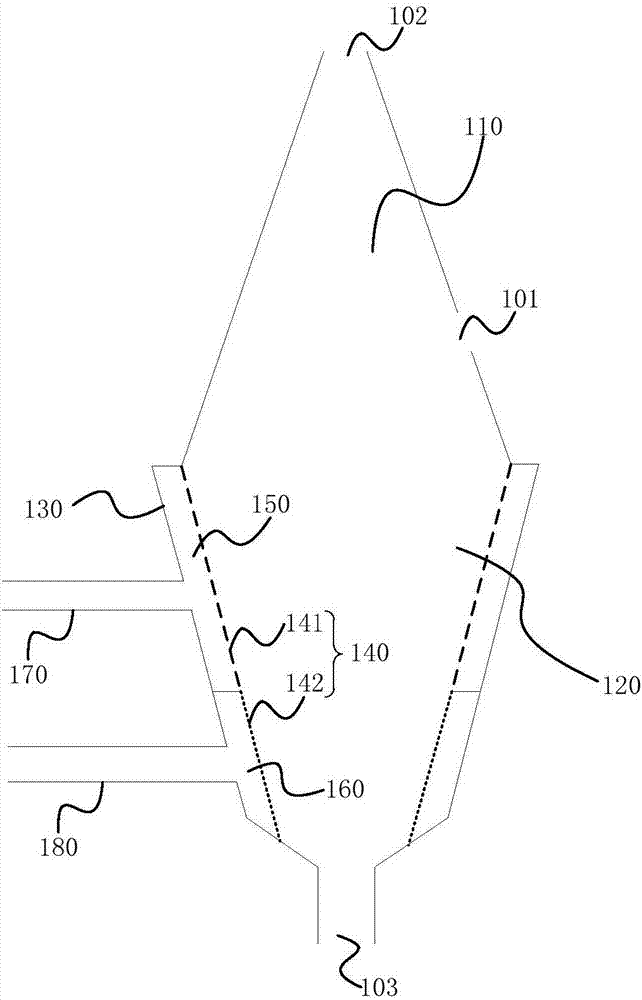

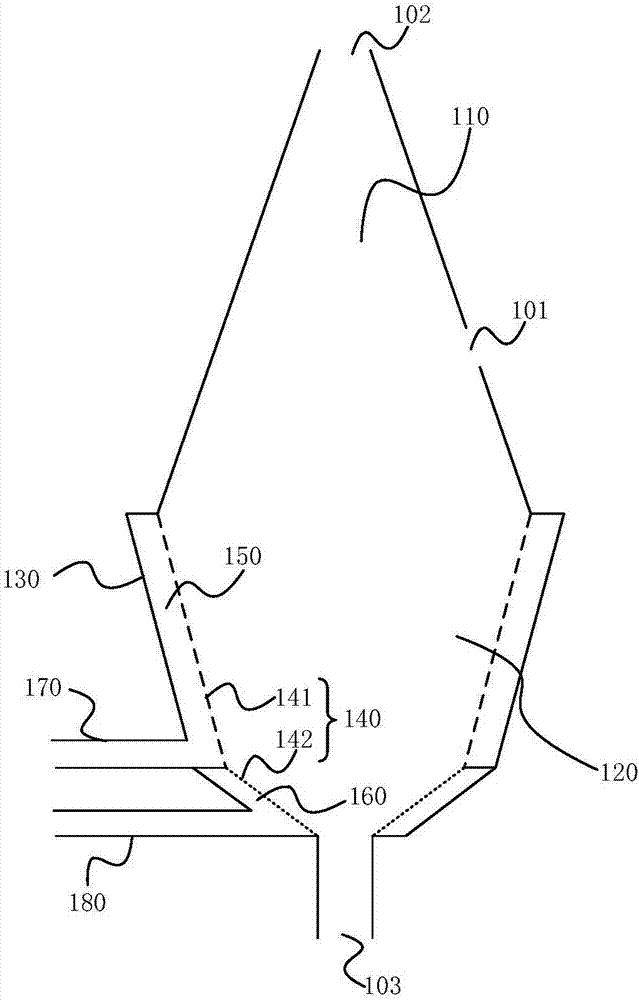

[0101] The organic solids with an average particle size not higher than 6mm are supplied from the raw material bin to the sorting device for sorting treatment. The sedimentation velocity of the material is calculated according to the density characteristics of the material and the expected sorting effect, and the material is sorted according to the speed of the rising airflow. The air volume of the device in order to obtain low ash organic solids and high ash organic solids;

[0102] Supplying low-ash organic solids to a crushing device for crushing treatment, so as to obtain low-ash organic scraps with a size not greater than 1mm;

[0103] Supply the low-ash organic scrap and powdered quicklime to the molding device for mixing and agglomeration, so as to obtain mixed pellets;

[0104] Supplying the mixed pellets to the first pyrolysis device to perform the first pyrolysis treatment at 500-1000 degrees Celsius, so as to obtain the first artificial petroleum, the first hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com