Vehicle gear cold extrusion process

An automotive gear and cold extrusion technology, which is applied to wheels, metal material coating technology, manufacturing tools, etc., can solve the problem of low gear precision, achieve high production efficiency, improve material utilization, and reduce the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

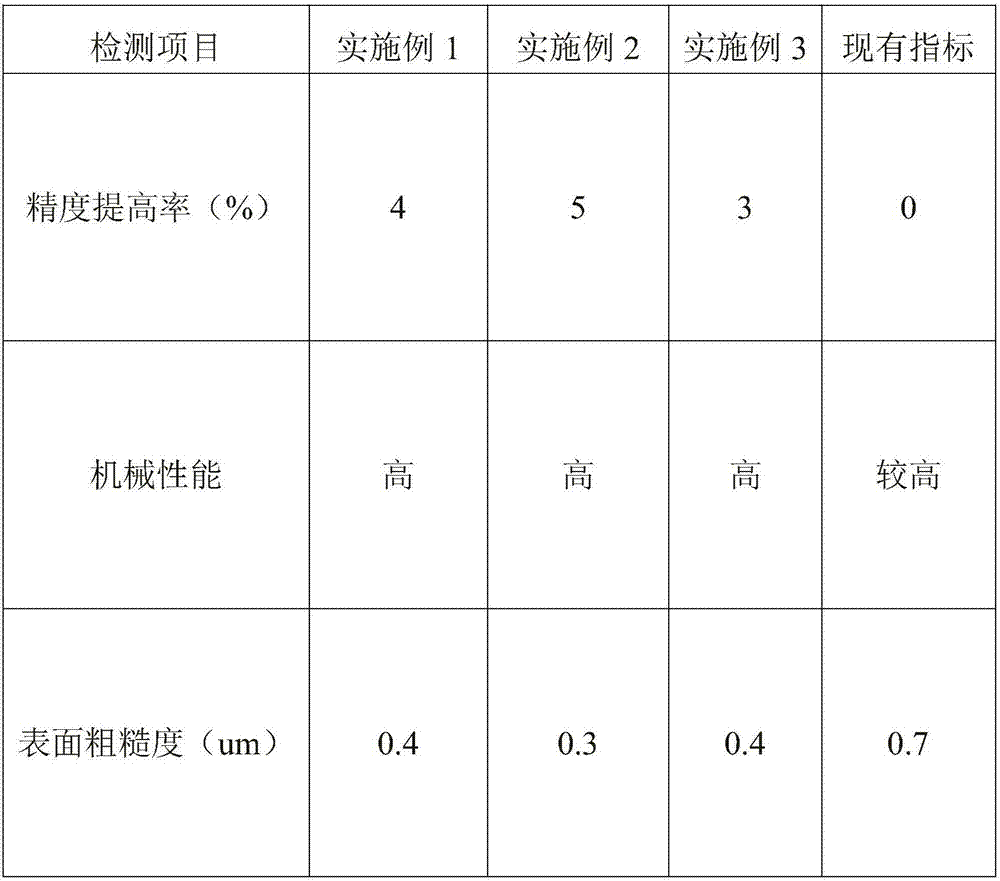

Examples

Embodiment 1

[0030] A kind of automobile gear cold extrusion process, comprises the following steps:

[0031] (1) detection

[0032] First, carry out chemical analysis, metallographic inspection and mechanical performance inspection on the billet, and save the qualified products for later use;

[0033] (2) Cutting

[0034] Pickling the blank for 8 minutes in a pickling pool, then rinsing once with distilled water, sawing after drying, the accuracy of the blanking size is 0.1mm, and the blanking adopts a high-precision band sawing machine, and the high-precision The thickness of the saw blade of the precision band sawing machine is 0.90mm, and the gap of the saw blade is 1.00mm;

[0035] (3) Cutting process

[0036] Then, the blank surface after blanking is cut, and the surface roughness of the blank after the cutting is 1.2um;

[0037] (4) Spheroidizing annealing

[0038] Put the cut blank into an electric furnace for annealing treatment, heat the temperature in the furnace to 600°C, ...

Embodiment 2

[0048] A kind of automobile gear cold extrusion process, comprises the following steps:

[0049] (1) detection

[0050] First, carry out chemical analysis, metallographic inspection and mechanical performance inspection on the billet, and save the qualified products for later use;

[0051] (2) Cutting

[0052] Pickling the blank for 10min in a pickling tank, then rinsing it twice with distilled water, and sawing after drying. The accuracy of the blanking size is 0.15mm, and the blanking adopts a high-precision band sawing machine. The thickness of the saw blade of the precision band sawing machine is 0.95mm, and the gap of the saw blade is 1.50mm;

[0053] (3) Cutting processing

[0054] Then, the blank surface after blanking is cut, and the surface roughness of the blank after the cutting is 1.4um;

[0055] (4) Spheroidizing annealing

[0056] Put the cut blank into an electric furnace for annealing treatment, heat the temperature in the furnace to 700°C, and then cool i...

Embodiment 3

[0066] A kind of automobile gear cold extrusion process, comprises the following steps:

[0067] (1) detection

[0068] First, carry out chemical analysis, metallographic inspection and mechanical performance inspection on the billet, and save the qualified products for later use;

[0069] (2) Cutting

[0070] Pickling the blank for 12min in a pickling tank, then rinsing it 3 times with distilled water, sawing after drying, the precision of the blanking size is 0.2mm, and the blanking adopts a high-precision band sawing machine, and the high The thickness of the saw blade of the precision band sawing machine is 1.00mm, and the gap of the saw blade is 2.00mm;

[0071] (3) Cutting processing

[0072]Then, the blank surface after blanking is cut, and the surface roughness of the blank after the cutting is 1.6um;

[0073] (4) Spheroidizing annealing

[0074] Put the cut blank into an electric furnace for annealing treatment, heat the temperature in the furnace to 800°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com