Method for obtaining Rosellinia sp.fungi imperfecti spore-free mycete capable of producing PF1022

A technology of PF1022 and half-knowledge bacteria, which is applied in the field of obtaining half-knowledge fungus aseptic molds for the production of PF1022, can solve the problems of low yield of PF1022A, selection of unfavorable strains, and small difference in colony morphology, etc., to achieve industrial production and yield High, yield-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composition of the hyperosmotic plate solid medium is: 20% potato, 2% glucose, 1.8% agar and KCl with a concentration of 0.7 mol / L, and the balance is water, and the percentages are mass volume percentages.

[0031] The hyperosmotic plate solid medium is prepared by the following method: cut 200g of potatoes into small pieces and put them in a pot, add water and heat to boiling, keep for 20min, filter with 8 layers of gauze, add water to 1000ml, add 20g of glucose , 18g agar and 0.7mol KCl.

[0032] Except that the composition of the slant medium does not contain KCl, other components and preparation methods are the same as those of the hyperosmotic plate solid medium.

[0033] The composition of the solid culture medium of the comparison plate is: 20% potato, 2% glucose and 1.8% agar, and the balance is water, and the percentage is mass volume percentage.

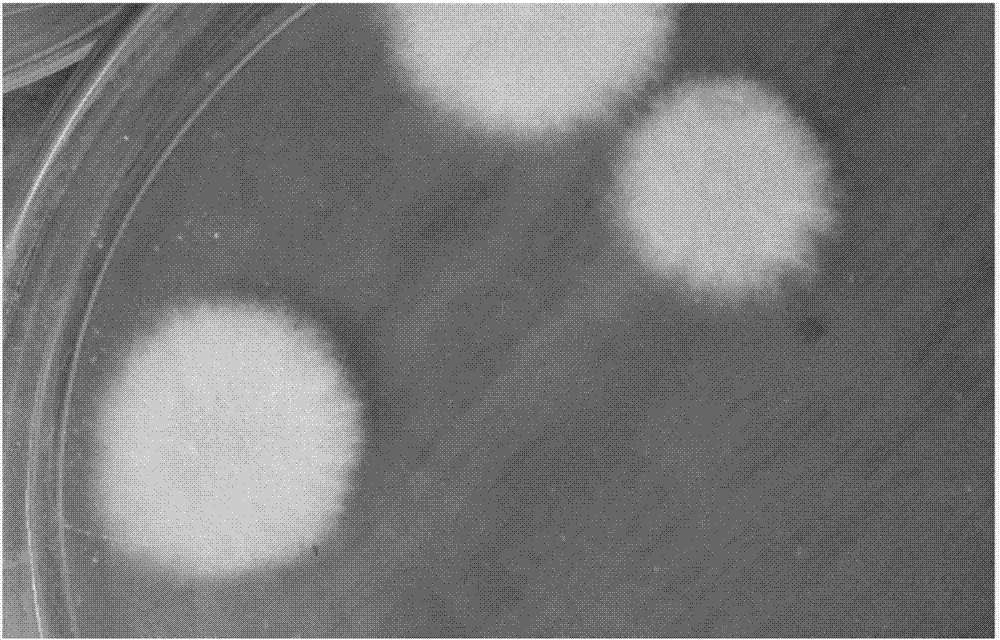

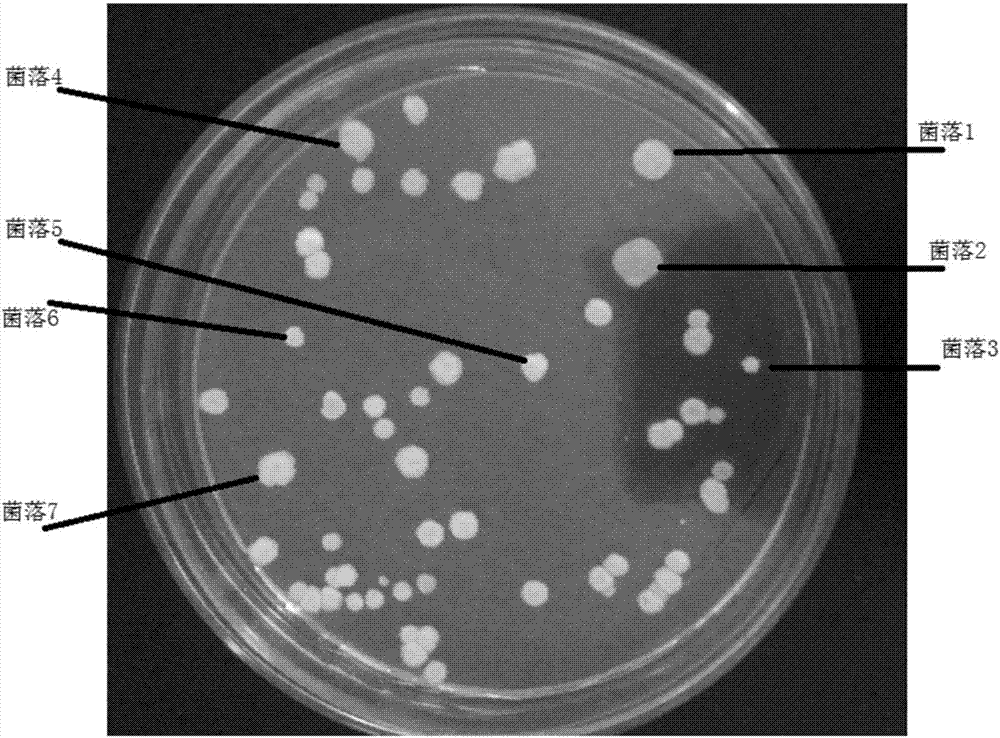

[0034] (1), after grinding Rosellinia.sp.PF1022 preserved in glycerol in a homogenizer, dilute to 10 -3 ~10...

Embodiment 2

[0041] The composition of hyperosmotic plate solid medium is: 20% potato, 2% glucose, 1.8% agar and concentration are respectively 0.1mol / L, 0.3mol / L, 0.5mol / L, 0.7mol / L, 0.9mol / L or The KCl of 1mol / L, balance is water, and described percentage is mass volume percentage.

[0042] Cut 200g of potatoes into small pieces and put them in a pot, add water, heat to boiling, keep for 30min, filter with 8 layers of gauze, add water to 1000ml, add 2g of glucose, 18g of agar and KCl.

[0043] The composition of the slant medium is: 20% potato, 2% glucose and 1.8% agar, and the balance is water, and the percentage is mass volume percentage.

[0044] The preparation method of the slant medium is the same as the preparation method of the hypertonic plate solid medium.

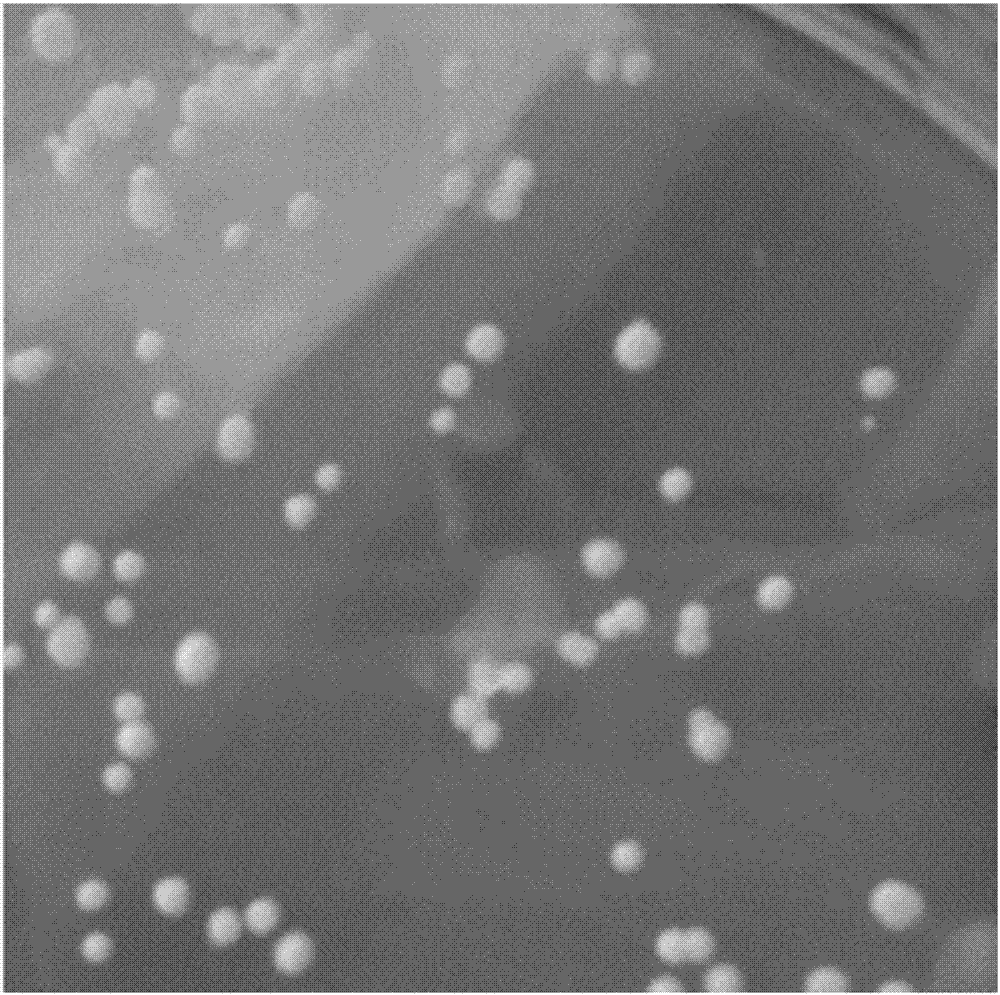

[0045] (1), after grinding Rosellinia.sp.PF1022 preserved in glycerol in a homogenizer, dilute to 10 -3 ~10 -4 1 / ml to obtain the dilution, take 0.1ml of the dilution and spread it evenly on the solid medium of the hyper...

Embodiment 3

[0054] The composition of hyperosmotic plate solid medium is: 20% potato, 2% glucose, 1.8% agar and concentration are respectively 0.1mol / L, 0.3mol / L, 0.5mol / L, 0.7mol / L, 0.9mol / L or 1mol / L MgSO 4 .7H 2 O, the balance is water, and the percentage is mass volume percentage.

[0055] The composition of the slant medium is: 20% potato, 2% glucose and 1.8% agar, and the balance is water, and the percentage is mass volume percentage.

[0056] All the other conditions are completely consistent with Example 2. The results are shown in Table 3, and the data in Table 3 illustrate that different concentrations of MgSO 4 .7H 2 O can affect the fermentative unit of PF1022A, with MgSO 4 .7H 2 With the increase of O concentration, the positive mutation rate of the obtained strain also showed a corresponding increase. Wherein when MgSO 4 .7H 2 When the concentration of O was 0.5mol / L or 0.7mol / L, the rate of positive mutation increased significantly. Example 3 The results produced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com