Temperature humidification system for liquor making plant

A humidification system and workshop technology, applied in air humidification systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as brewing failure, unreachable air humidity, and uncontrollable brewing temperature, and save water resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

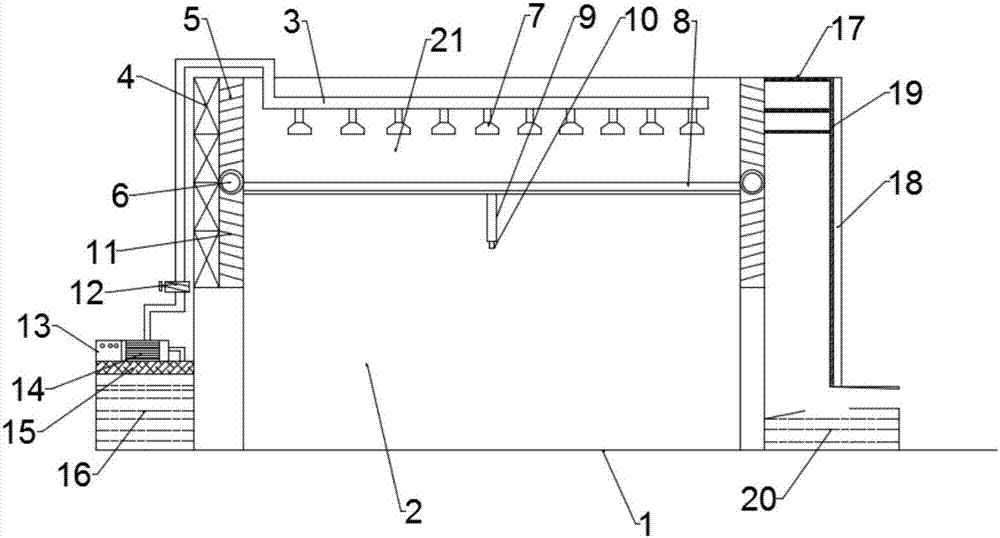

[0018] Such as figure 1 As shown, the present invention provides a technical solution, a temperature humidification system for a liquor brewing workshop, including a workshop 1, a wet film layer 8 is arranged on the top of the workshop 1, and the wet film layer 8 is placed horizontally in the workshop 1 On the walls on both sides, and the workshop 1 is divided into two parts: the brewing chamber 2 and the compartment 21 through the wet film layer 8, the middle bottom of the wet film layer 8 is provided with a telescopic rod 10, and the other end of the telescopic rod 10 is provided with a The temperature and humidity sensor 10, the two side walls of the workshop 1 are provided with an upper filter screen window 5 and a lower filter screen window 11, the upper filter screen window 5 and the lower filter screen window 11 are louver type, and the upper filter screen A motor 6 is arranged between the window 5 and the lower filter screen window 11, a fan unit 4 is arranged on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com