Testing method and system for achieving automatic testing of seeker whole performance

A test system and automatic test technology, applied in the field of measurement and control, can solve problems such as poor consistency, inability to guarantee consistency and high precision, and achieve the effects of increased safety and reliability, flexible test process optimization, and easy viewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

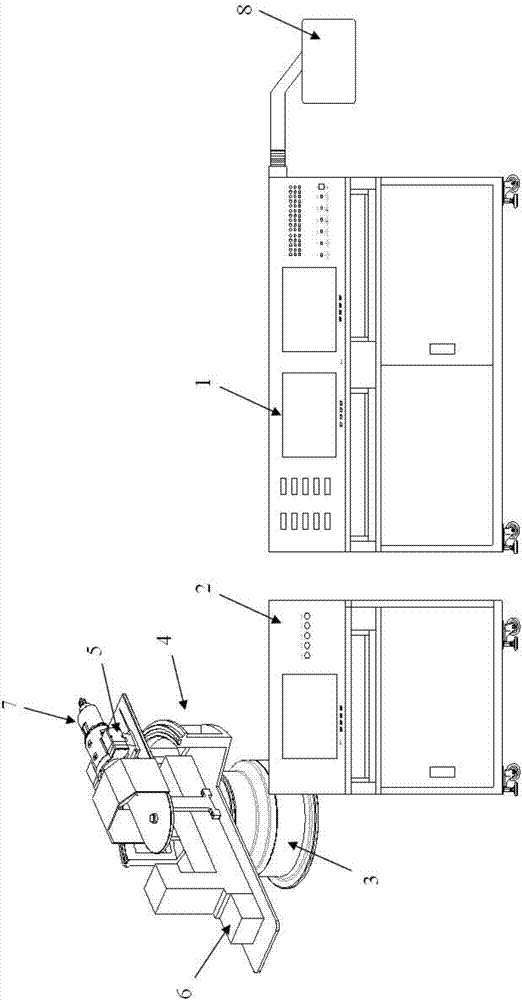

[0054] Such as figure 1 As shown, the automated testing system of the present invention adopts a generalized, modularized, and standardized design scheme, and the subsequent function expansion of the equipment as well as repair and maintenance are convenient. The hardware system constructed for this purpose includes the seeker main control cabinet 1, the equipment main control cabinet 2, the tracking turntable 3, the automatic deflection device 4, the rotating bracket 5, the collimator 6 and the infrared target source 7 connected by cables. .

[0055] The seeker main control cabinet 1 includes: seeker signal observation area (with internal circuit for waveform display, signal detection, and test combination), seeker control area, power supply combination, industrial computer combination, camera monitor, etc. Among them, the seeker signal observation area can observe all the signals of the seeker that need to be observed, display signal graphics through an oscilloscope, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com