Composite layered positive electrode material, and preparation method and purpose thereof

A cathode material and composite layer technology, applied in the field of new energy materials, can solve the problems of inability to effectively adjust the thickness, uneven material coating, etc., and achieve easy mass production, controllable coating thickness, and uniform coating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing a composite layered positive electrode material, which can realize controllable adjustment of the thickness of the coating layer on the surface of the layered positive electrode material.

[0057] Specific steps are as follows:

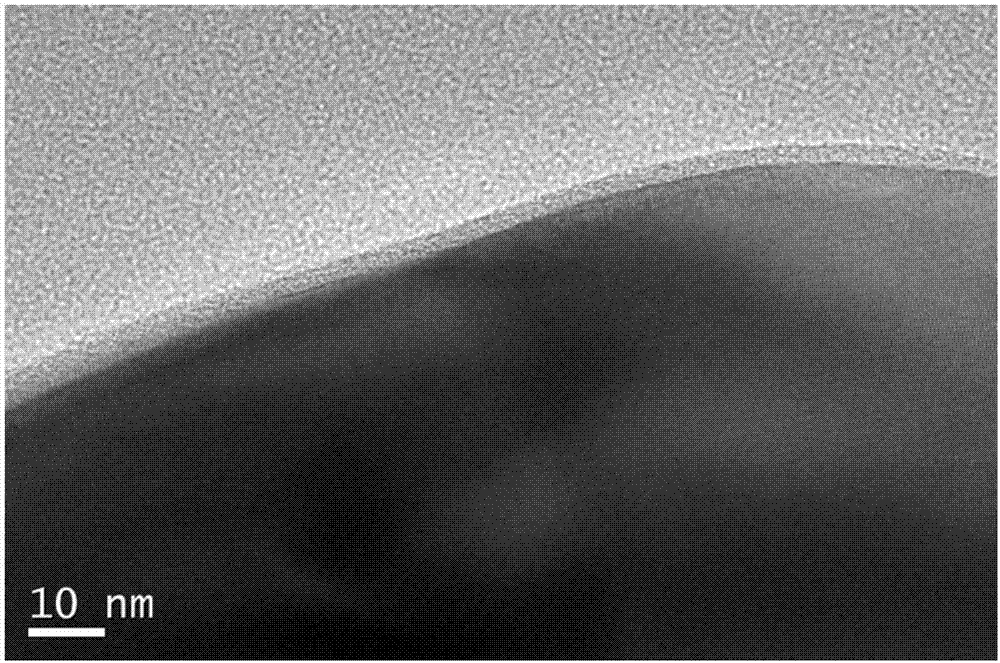

[0058] Weigh 13g of aluminum isopropoxide and dissolve it in 1L of ethanol. After it is completely dissolved and dispersed, weigh 1000g of LiNi 0.8 co 0.1 mn 0.1 o 2 Add the positive electrode material, then add 5g of auxiliary polyvinylpyrrolidone (PVP-K30), and stir in a stirring tank for 0.5h, remove the solvent by spray drying, and heat-treat the dried material at 500°C for 3h to obtain Al 2 o 3 Coated LiNi 0.8 co 0.1 mn 0.1 o 2 For the positive electrode material, that is, the composite layered positive electrode material, the thickness of the coating layer is 5nm±1nm.

[0059] figure 1 The TEM image of the composite layered positive electrode material prepared in this example shows that the surface of the ...

Embodiment 2

[0061] A method for preparing a composite layered positive electrode material, which can realize controllable adjustment of the thickness of the coating layer on the surface of the layered positive electrode material.

[0062] Specific steps are as follows:

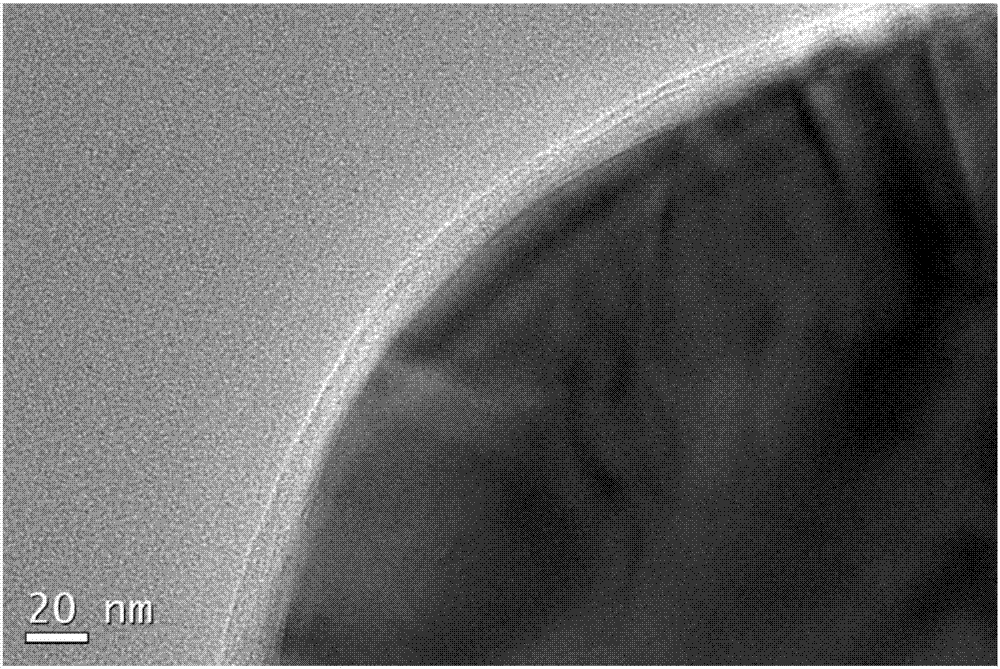

[0063] Weigh 13g of aluminum isopropoxide and dissolve it in 1L of ethanol. After it is completely dissolved and dispersed, weigh 1000g of LiNi 0.8 co 0.1 mn 0.1 o 2 Add the positive electrode material, then add 5g of auxiliary polyvinylpyrrolidone (PVP-K30), and stir in a stirring tank for 3h, remove the solvent by spray drying, and heat-treat the dried material at 500°C for 3h to obtain Al 2 o 3 Coated LiNi 0.8 co 0.1 mn 0.1 o 2 The thickness of the coating layer of the positive electrode material, that is, the composite layered positive electrode material is 19nm±1nm.

[0064] figure 2 The TEM image of the composite layered positive electrode material prepared in this example shows that the surface of the ma...

Embodiment 3

[0066] A method for preparing a composite layered positive electrode material, which can realize controllable adjustment of the thickness of the coating layer on the surface of the layered positive electrode material.

[0067] Specific steps are as follows:

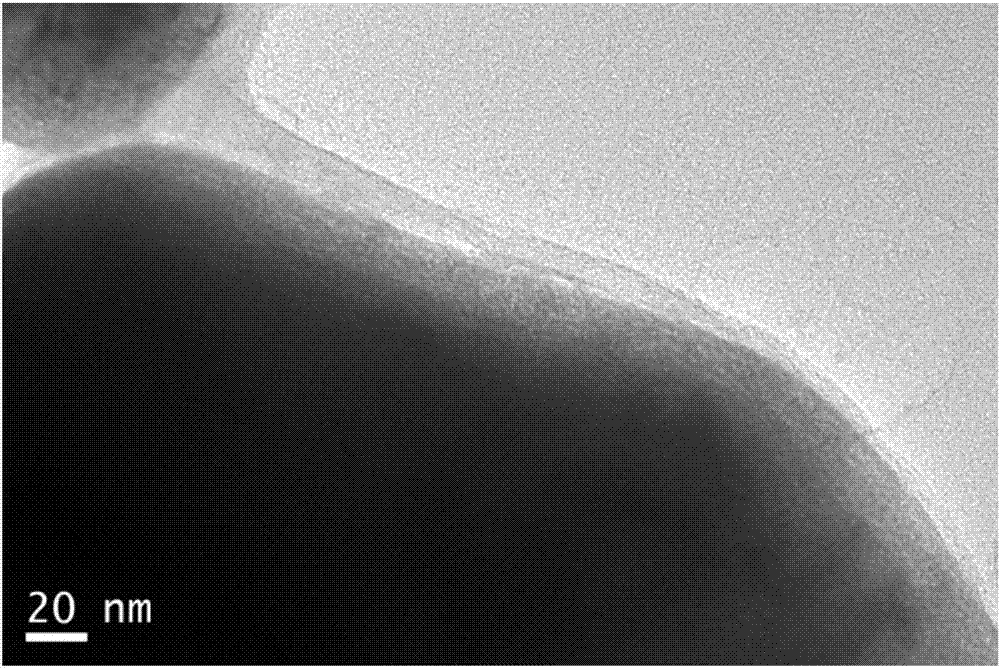

[0068] Weigh 13g of aluminum isopropoxide and dissolve it in 1L of ethanol. After it is completely dissolved and dispersed, weigh 1000g of LiNi 0.8 co 0.1 mn 0.1 o 2 Add the positive electrode material, then add 10g of auxiliary polyvinylpyrrolidone (PVP-K30), and stir in a stirring tank for 3h, remove the solvent by spray drying, and heat-treat the dried material at 500°C for 3h to obtain Al 2 o 3 Coated LiNi 0.8 co 0.1 mn 0.1 o 2 The thickness of the coating layer of the positive electrode material, that is, the composite layered positive electrode material is 10nm±1nm.

[0069] image 3 The TEM image of the composite layered cathode material prepared in this example shows that the surface of the material is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com