Lithium secondary battery

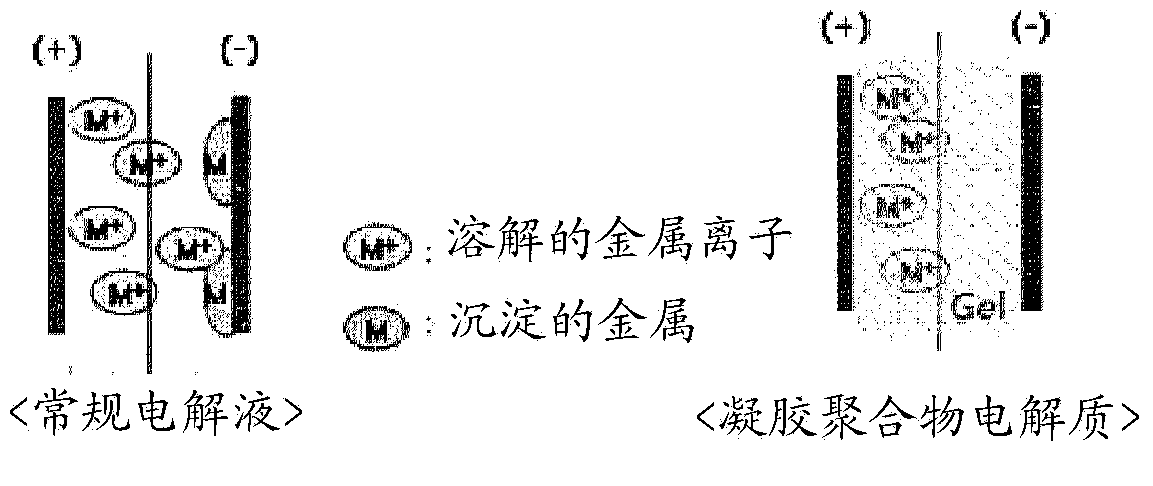

A lithium secondary battery and electrolyte technology, applied in secondary batteries, lithium storage batteries, batteries, etc., can solve the problems of increasing resistance and reducing the life performance of lithium secondary batteries, so as to improve battery life, excellent capacity performance, reduce effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] According to an exemplary embodiment of the present invention, the method may include: (a) a step of inserting an electrode assembly consisting of a positive electrode, a negative electrode, and a separator disposed between the positive electrode and the negative electrode into the battery case; (b) inserting After the composition of the gel polymer electrolyte is injected into the battery case, the step of polymerizing the composition to form an electrolyte.

[0071] In-situ polymerization in lithium secondary batteries may be performed by thermal polymerization. In this case, the desired polymerization time ranges from about 2 minutes to 12 hours, and the thermal polymerization temperature may range from 30°C to 100°C.

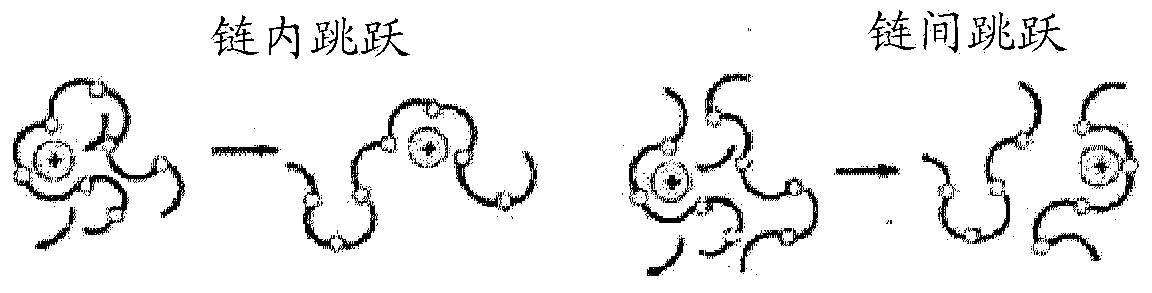

[0072] When polymerization-based gelation is performed, a gel polymer electrolyte is formed. Specifically, a gel polymer is formed in which polymerizable monomers are cross-linked with each other through a polymerization reaction, and the gel polymer...

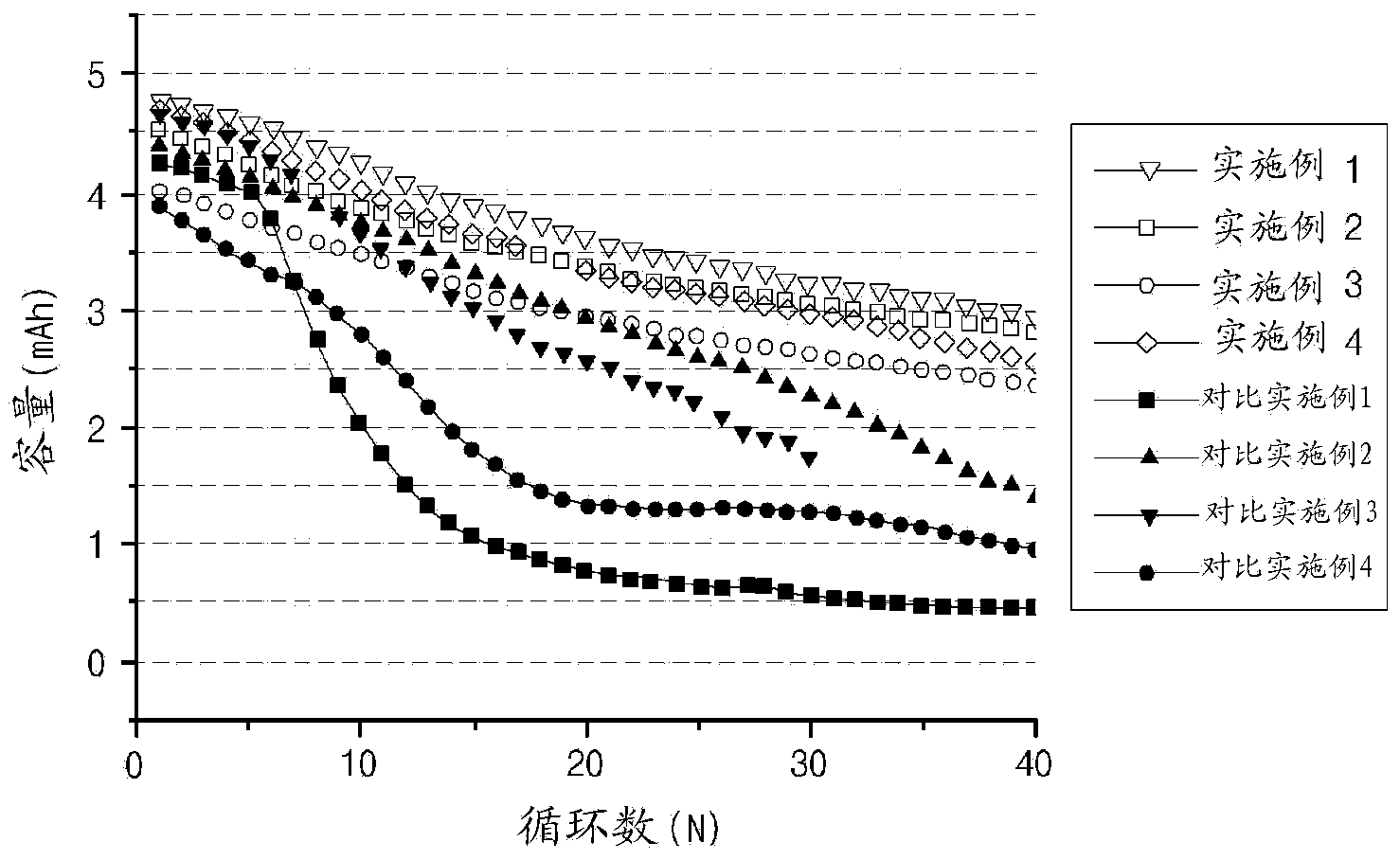

Embodiment 1

[0095]

[0096] The electrolyte is passed through the LiPF 6 prepared by dissolving in a non-aqueous electrolyte solvent having a composition of ethylene carbonate (EC) and ethylmethyl carbonate (EMC) at a volume ratio of 1:2 to obtain LiPF 6 The concentration is 1M. The composition for gel polymer electrolyte is obtained by adding 5 parts by weight of polymerizable monomers (2.5 parts by weight of 2-cyanoethyl acrylate, and 2.5 parts by weight of bis(trimethylolpropane) tetraacrylate) and 0.25 parts by weight of tert-butyl peroxy-2-ethylhexanoate as a polymerization initiator, based on 100 parts by weight of the electrolyte solution.

[0097]

[0098] Positive electrode preparation

[0099] The positive electrode mixture slurry is prepared by the following method: 94% by weight of Li[Li 0.29 Ni 0.14 co 0.11 mn 0.46 ]O 2 , 3% by weight of carbon black (carbon black) as a conductive agent, and 3% by weight of polyvinylidene fluoride (PVdF) as a binder are added to ...

Embodiment 2

[0106] A coin-shaped secondary battery was prepared in the same manner as in Example 1, except that in preparing the composition for a gel polymer electrolyte of Example 1, 2-cyanoethoxyethyl acrylate was used to Instead of 2-cyanoethyl acrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com