Negative electrode material for batteries and method for preparing negative electrode material

A technology of negative electrode materials and positive electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of capacity decay, low electronic conductivity, and small diffusion speed of lithium ions, and achieve good capacity performance with a simple and easy method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

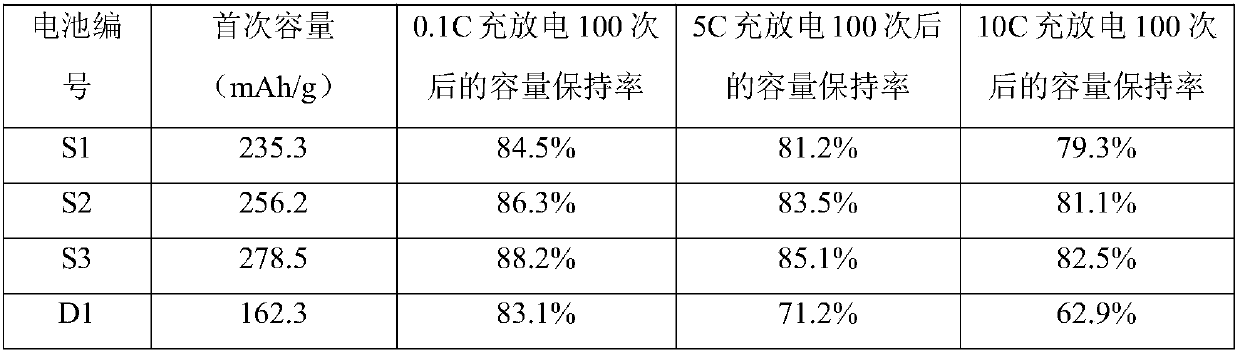

Examples

Embodiment 1

[0028] This embodiment provides a negative electrode material for batteries, including a core structure and a shell structure. The core structure includes modified lithium titanate and modified TiNb with a mass ratio of 2:1. 2 o 7 , modified lithium titanate is lithium titanate doped with silver, modified TiNb 2 o 7 TiNb modified with carbon nanotubes 2 o 7 ; The shell structure is a carbon layer.

[0029] The particle size of the core structure is 1 μm-15 μm. The thickness of the shell structure is 500nm-3μm. In the modified lithium titanate, the mass percentage of silver is 1%. Modified TiNb 2 o 7 In, the mass percentage of carbon nanotubes is 10%, TiNb 2 o 7 has a porous structure, and TiNb 2 o 7 intertwined with carbon nanotubes.

[0030] Its preparation method at least includes the following steps:

[0031] The first step, the preparation of modified lithium titanate: titanium dioxide, lithium carbonate and silver nitrate are added to the ball mill tank acco...

Embodiment 2

[0036] This embodiment provides a negative electrode material for batteries, including a core structure and a shell structure. The core structure includes modified lithium titanate and modified TiNb with a mass ratio of 1:2. 2 o 7 , modified lithium titanate is lithium titanate doped with silver, modified TiNb 2 o 7 TiNb modified with carbon nanotubes 2 o 7 ; The shell structure is a carbon layer.

[0037] The particle size of the core structure is 1 μm-15 μm. The thickness of the shell structure is 500nm-3μm. In the modified lithium titanate, the mass percentage of silver is 0.5%. Modified TiNb 2 o 7 In, the mass percentage of carbon nanotubes is 15%, TiNb 2 o 7 has a porous structure, and TiNb 2 o 7 intertwined with carbon nanotubes.

[0038] Its preparation method at least includes the following steps:

[0039] The first step, the preparation of modified lithium titanate: titanium dioxide, lithium carbonate and silver nitrate are added to the ball mill tank ac...

Embodiment 3

[0044] This embodiment provides a negative electrode material for batteries, including a core structure and a shell structure. The core structure includes modified lithium titanate and modified TiNb with a mass ratio of 1:4. 2 o 7 , modified lithium titanate is lithium titanate doped with silver, modified TiNb 2 o 7 TiNb modified with carbon nanotubes 2 o 7 ; The shell structure is a carbon layer.

[0045] The particle size of the core structure is 1 μm-15 μm. The thickness of the shell structure is 500nm-3μm. In the modified lithium titanate, the mass percentage of silver is 0.8%. Modified TiNb 2 o 7 In, the mass percentage of carbon nanotubes is 8%, TiNb 2 o 7 has a porous structure, and TiNb 2 o 7 intertwined with carbon nanotubes.

[0046] Its preparation method at least includes the following steps:

[0047] The first step, the preparation of modified lithium titanate: titanium dioxide, lithium carbonate and silver nitrate are added to the ball mill tank acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com