Preparation method of modified monocrystalline ternary cathode material for lithium ion batteries

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of difficult structure modification of secondary spherical particles, degradation of electrochemical performance, and small particle size of primary particles, etc., to achieve excellent Capacity performance and rate performance, improvement of surface stability, and improvement of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

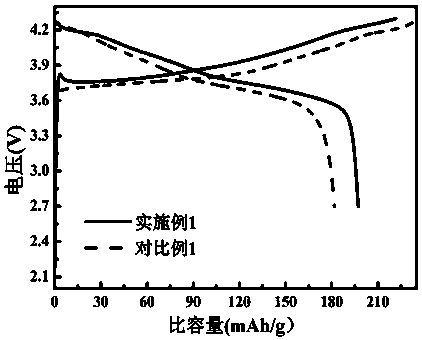

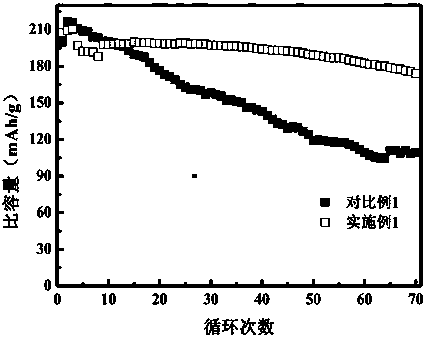

Embodiment 1

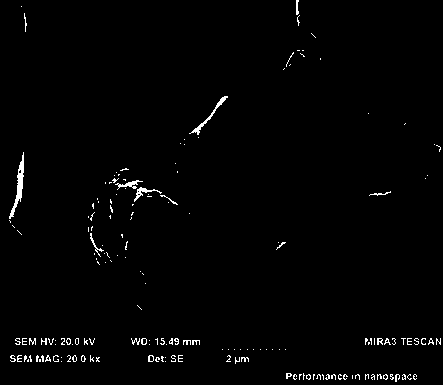

[0037] This example is a magnesium oxide coated single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 A method for preparing a ternary cathode material.

[0038] The mass percentage of the magnesium oxide is 1 wt%, and the magnesium oxide is in an amorphous state in a single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 A coating layer is formed on the surface of the ternary positive electrode material, and the positive electrode material is a particle with a particle diameter of 3-8 μm.

[0039] This embodiment includes the following steps:

[0040] (1) Single crystal LiNi coated with 1% MgO by mass fraction 0.8 co 0.1 mn 0.1 o 2 preparation of

[0041] Weigh 10.0000 g single crystal ternary cathode material NCM811 precursor and mix it with 13% excess lithium hydroxide according to the stoichiometric ratio according to the ball material ratio of 1:10. After ball milling at 400 rpm for 2 h, the The mixture was sintered at a temperature of 1000 °C, and then passed through a 400-mesh siev...

Embodiment 2

[0046] This example is a magnesium oxide coated single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 Preparation method of ternary cathode material:

[0047] The mass percentage of the magnesium oxide is 2 wt%, and the magnesium oxide is in an amorphous state in the single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 A coating layer is formed on the surface of the ternary positive electrode material, and the positive electrode material is a particle with a particle diameter of 3-8 μm.

[0048] This embodiment includes the following steps:

[0049] (1) Single crystal LiNi coated with 2% MgO 0.8 co 0.1 mn 0.1 o 2 preparation of

[0050] Weigh 10.0000 g of the single crystal ternary cathode material NCM811 precursor and mix it with 10% excess lithium hydroxide according to the stoichiometric ratio according to the ball-to-material ratio of 1:10. After ball milling at a speed of 300 rpm for 5 h, the The mixture was sintered at a temperature of 900 °C and passed through a 400-mesh sieve to...

Embodiment 3

[0055] This embodiment is lanthanum oxide coated single crystal LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation method of ternary cathode material:

[0056] The mass percent content of the lanthanum oxide is 10 wt%, and the lanthanum oxide is in an amorphous state in a single crystal LiNi 0.6 co 0.2 mn 0.2 o 2 A coating layer is formed on the surface of the ternary positive electrode material, and the positive electrode material is a particle with a particle diameter of 3-8 μm.

[0057] This embodiment includes the following steps:

[0058] (1) Mass fraction 10%La 2 o 3 Coated single crystal LiNi 0.6 co 0.2 mn 0.2 o 2 preparation of

[0059] Weigh 10.0000 g of single crystal ternary cathode material NCM622 precursor and mix it with 9% excess lithium carbonate according to the stoichiometric ratio according to the ball-to-material ratio of 1:20. After ball milling at 100 rpm for 8 h, the The mixture was sintered at a temperature of 800 °C, and then passed through a 200-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com