Lithium ion capacitor and preparation method thereof

A lithium ion and capacitor technology, applied in the field of high energy density lithium ion capacitors and their preparation, can solve the problems of slow electrochemical response of battery-type negative electrodes, achieve good cycle stability, realize regulation, and realize energy density and rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

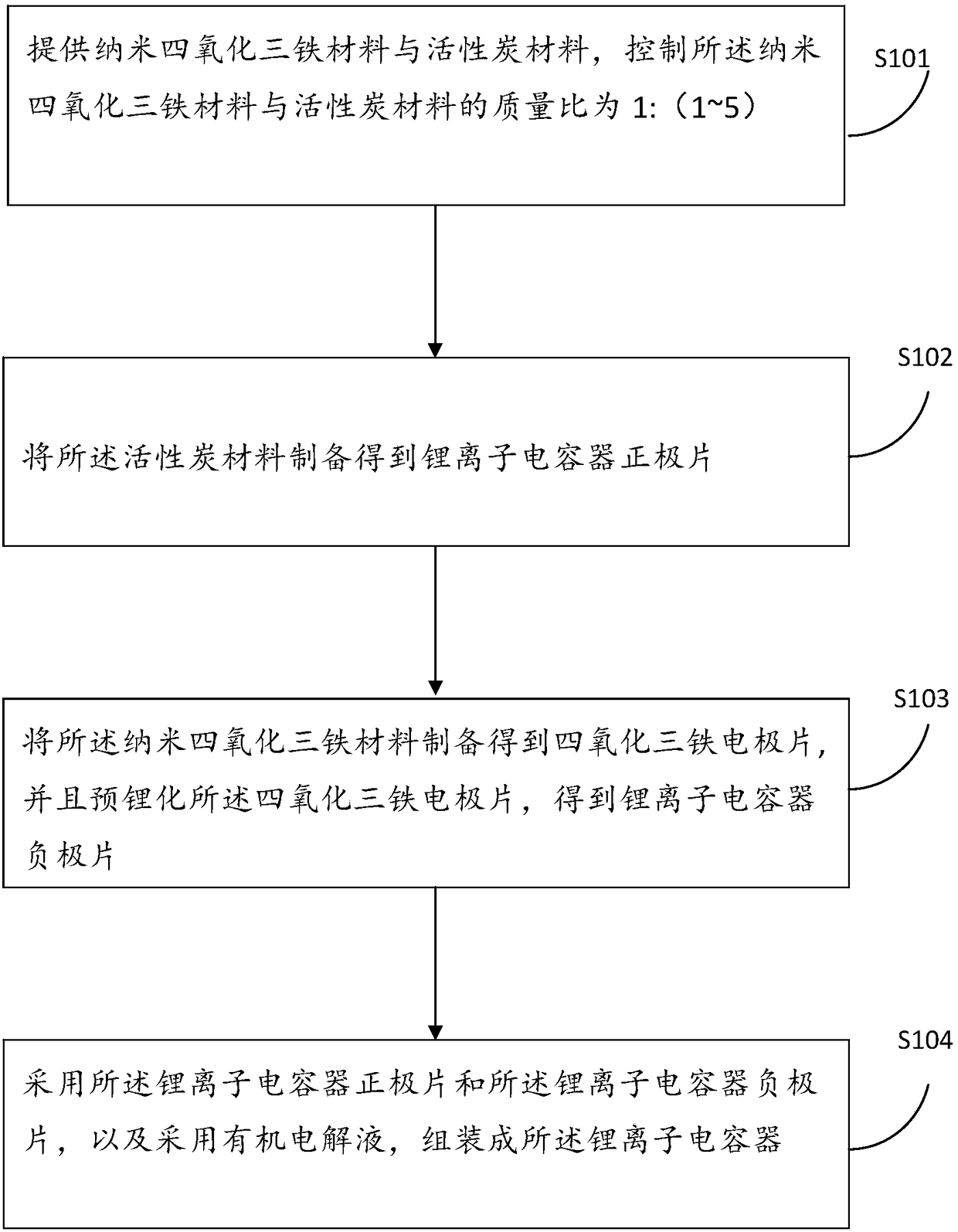

[0022] refer to figure 1 , The embodiment of the present invention provides a kind of preparation method of lithium ion capacitor, comprises the following steps:

[0023] S101: providing a nano-ferric oxide material and an activated carbon material, controlling the mass ratio of the nano-ferric oxide material to the activated carbon material to be 1:(1-5);

[0024] S102: preparing the active carbon material to obtain the positive electrode sheet of lithium ion capacitor;

[0025] S103: Prepare the nano-ferric oxide material to obtain the ferric oxide electrode sheet, and pre-lithiate the ferric oxide electrode sheet to obtain the negative electrode sheet of the lithium ion capacitor;

[0026] S104: Assembling the lithium ion capacitor by using the positive electrode sheet of the lithium ion capacitor and the negative electrode sheet of the lithium ion capacitor, and using an organic electrolyte.

[0027] In step S101, preferably, the specific surface area of the activated ...

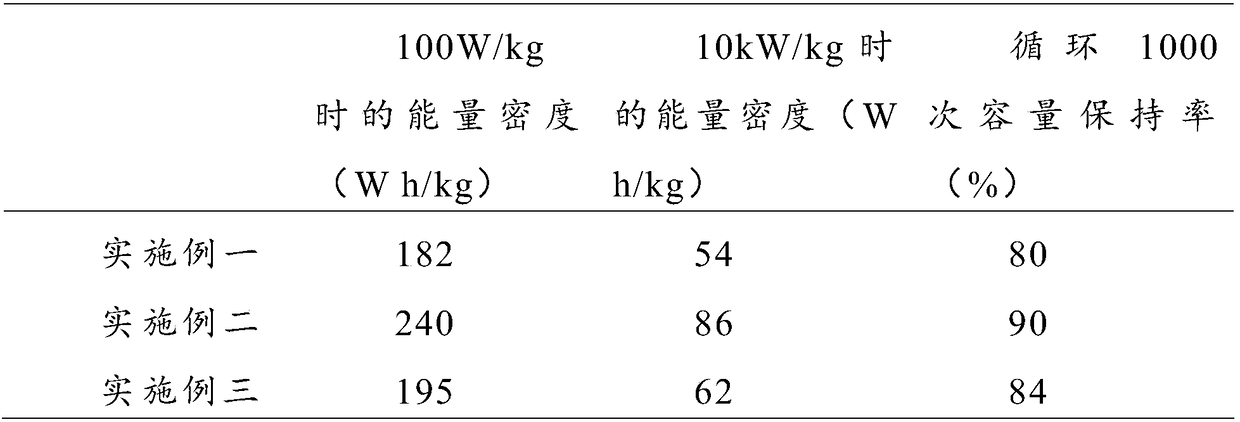

Embodiment 1

[0037] The preparation method of the high-energy lithium-ion capacitor with the nano ferric oxide material as the negative electrode comprises the following steps:

[0038] Provide nano ferric oxide material and activated carbon material, and control the mass ratio of nano ferric oxide material to activated carbon material to be 1:1.

[0039] The specific surface area is 1200m 2 / g, the pore volume is 0.5cm3 / g of activated carbon, mixed with conductive additive acetylene black, and binder PVDF according to the mass ratio of 75:10:15, and the organic solvent NMP was added to obtain the positive electrode slurry. The positive electrode slurry is coated on the aluminum foil, and the lithium ion capacitor positive electrode sheet is obtained after drying, rolling and punching.

[0040] Nano ferric oxide material, D 50 =70nm, mixed evenly with the conductive additive acetylene black, and the binder sodium alginate according to the mass ratio of 70:20:10, and added the solvent de...

Embodiment 2

[0043] The preparation method of the high-energy lithium-ion capacitor with the nano ferric oxide material as the negative electrode comprises the following steps:

[0044] Provide nano ferric oxide material and activated carbon material, and control the mass ratio of nano ferric oxide material to activated carbon material to be 1:2.

[0045] The specific surface area is 1600m 2 / g, the pore volume is 0.8cm 3 / g of activated carbon, mixed with the conductive additive Super P, and the binder PVDF according to the mass ratio of 80:10:10, and the organic solvent NMP was added to obtain the positive electrode slurry. The positive electrode slurry is evenly coated on the aluminum foil, and the positive electrode sheet of the lithium ion capacitor is obtained after drying, rolling and punching.

[0046] The nano iron ferric oxide negative electrode material, D 50 =150nm, mixed with the conductive additive acetylene black, and the binder sodium alginate according to the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com