Method for strengthening anaerobic dry fermentation hydrogen production of kitchen waste

A technology of food waste and dry fermentation, applied in the direction of fermentation, etc., can solve the problems of hydrogen consumption suppression and less reports, and achieve good research and application prospects, simple process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Implementation column 1:

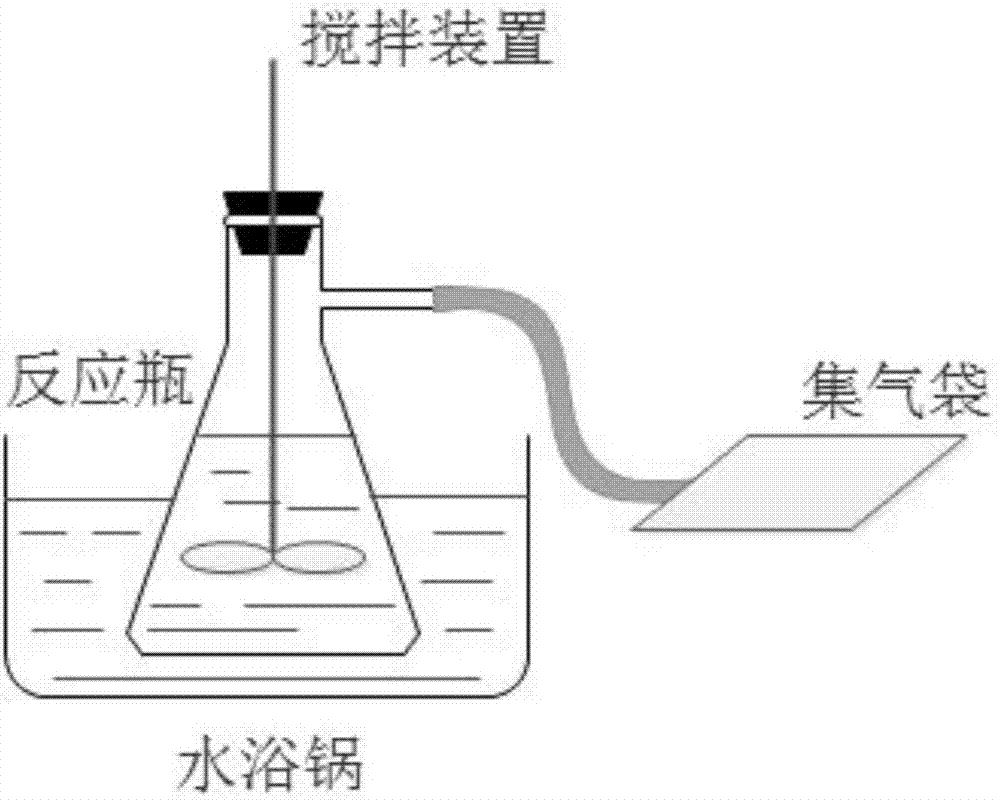

[0028] The schematic diagram of the experimental device is as follows: figure 1 As shown, the reaction temperature is 37°C, the gas volume is collected by a gas bag and then measured by the drainage method, and the hydrogen content is measured by a gas chromatograph. Before and after the anaerobic dry fermentation reaction, the concentration of carbohydrates, proteins, SCOD and liquid phase end fermentation products in the reaction system were measured; the determination methods were all analyzed by national standard methods (Table 1).

[0029] Table 1 Analysis items and methods

[0030]

[0031] In the experiment, 300g of anaerobic granular sludge, 100 pieces of dried kitchen waste and 0g, 0.3g, 0.6g, and 0.9g of chloroform were added to a 1L Erlenmeyer flask (Table 2).

[0032] Table 2 Experimental design

[0033]

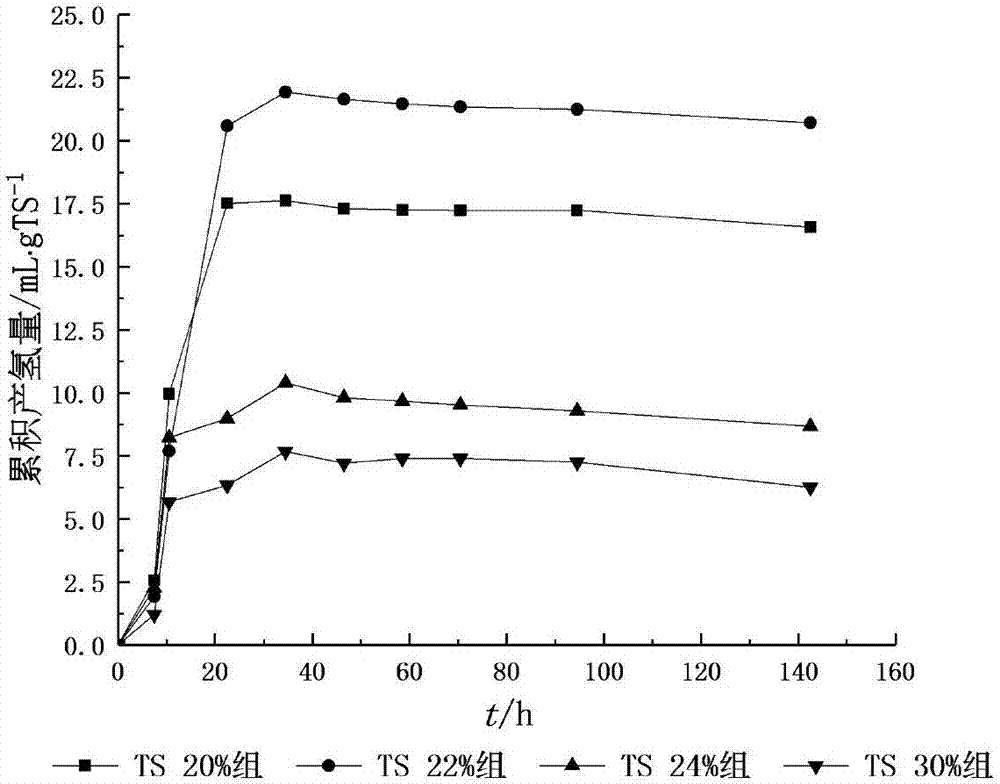

[0034] Example 2: Hydrogen production during anaerobic dry fermentation of food waste under different TS conditions

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com