Anti-nuclear radiation composite material

A technology of anti-nuclear radiation and composite materials, applied in the field of anti-nuclear radiation composite materials, can solve the problems of polluted environment, physical injury of operators, weak high-energy neutron protection ability, etc., and achieves less pores, dense coating and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

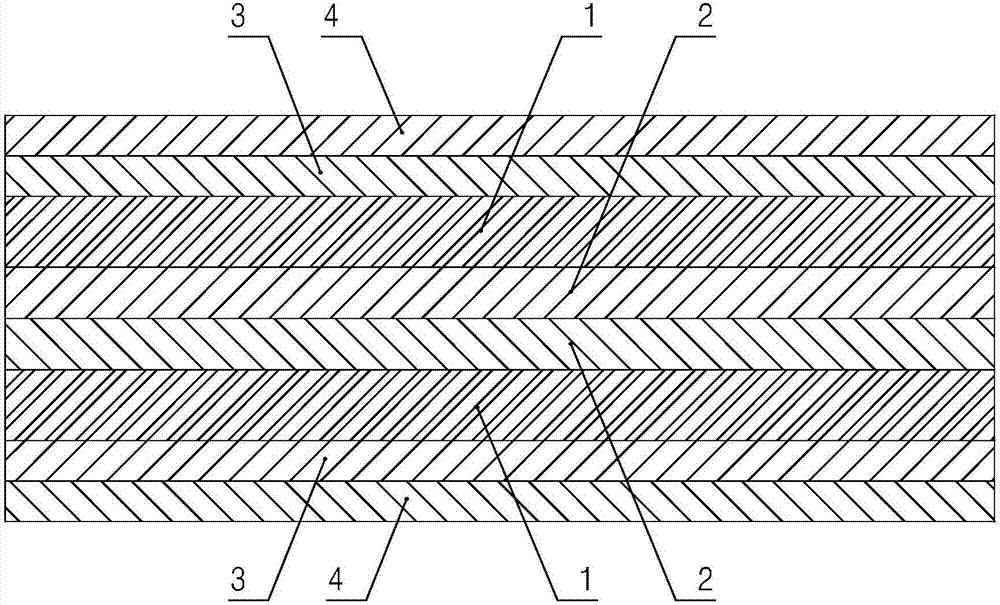

[0018] A specific embodiment of the anti-nuclear radiation composite material of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, a kind of anti-nuclear radiation composite material according to the present invention includes: a pair of stainless steel substrates 1, and two layers of protective high-energy neutron coatings are arranged on one side surface of each stainless steel substrate 1, and the inner side In order to protect the inner coating 3 for high-energy neutrons, and the outer coating 4 for protecting high-energy neutrons, the other surface of each stainless steel substrate 1 is provided with a layer of protective gamma-ray coating 2, thereby forming Anti-nuclear radiation plate, the inner coating 3 that can protect high-energy neutrons includes: 40-70 parts by weight of aluminum-based metal, 20-40 parts by weight of boron carbide and 10-20 parts by weight of samarium oxide, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com