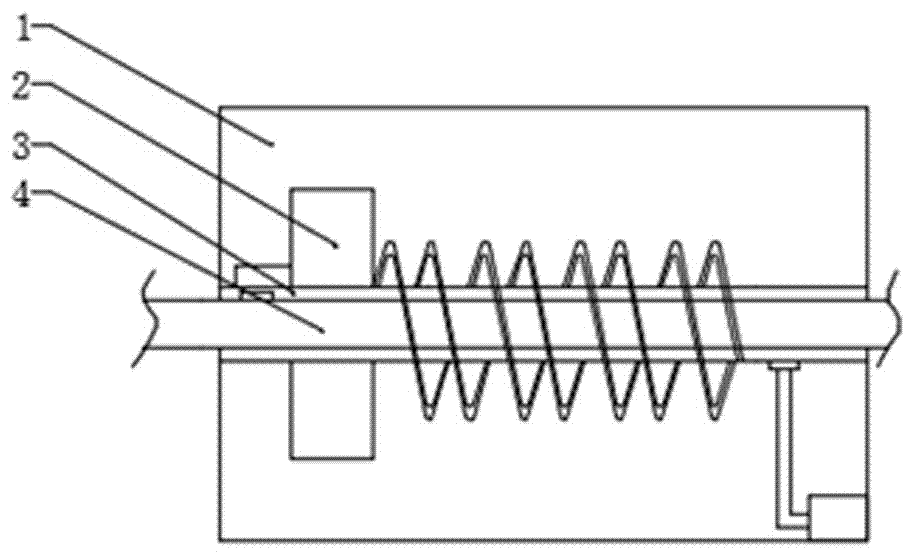

Heat exchanger for natural gas pressure adjusting station

A natural gas and heat exchanger technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as the inability to control the temperature of natural gas pipelines, the inability of heat exchangers to regulate natural gas pipelines, and the large damage to gas turbines. problems, to achieve the effect of high reliability, high security, and labor liberation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

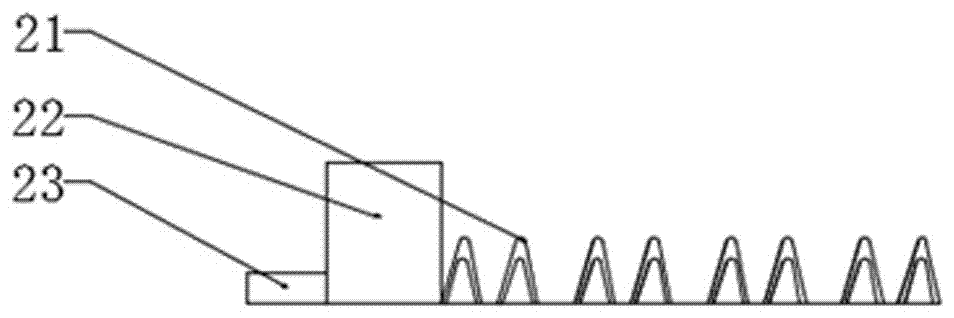

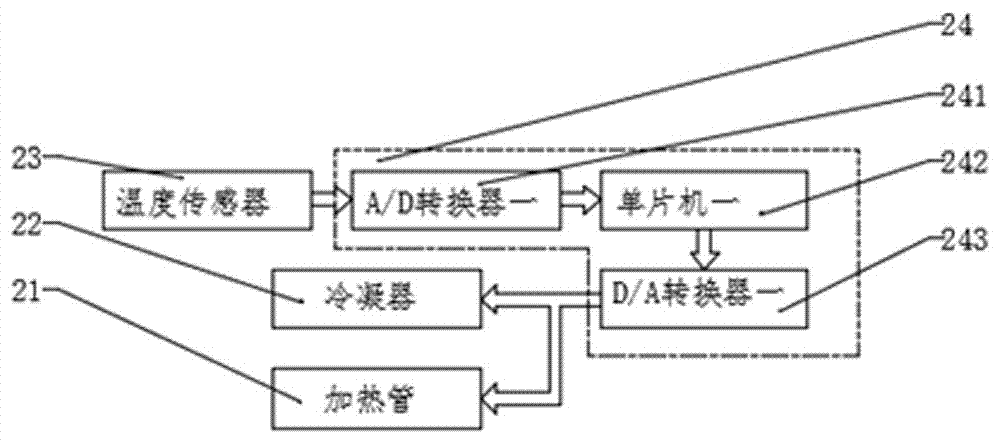

[0029]The specific embodiment: before the present invention starts to use, the staff first inputs the required natural gas temperature value of the gas turbine into the single-chip microcomputer one 242 as the initial value, and the air pressure value in the anti-leakage pipeline 32 when the natural gas is not leaked is input into the initial value as the initial value. In the single-chip microcomputer two 372, the staff then turns on the switch of the natural gas pipeline 4, and the present invention carries out temperature regulation to the natural gas pipeline 4, and the temperature sensor 23 receives the temperature signal and transmits the temperature signal to the A / D converter one 241, and the A / D conversion Device 1 241 converts the temperature signal into temperature data and transmits the temperature data to MCU 1 242. MCU 1 242 compares the temperature data with the initial value for calculation and processing. After processing, MCU 1 242 sends an instruction signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com