Composite binder for high-nickel ternary material, positive electrode paste, and preparation methods thereof

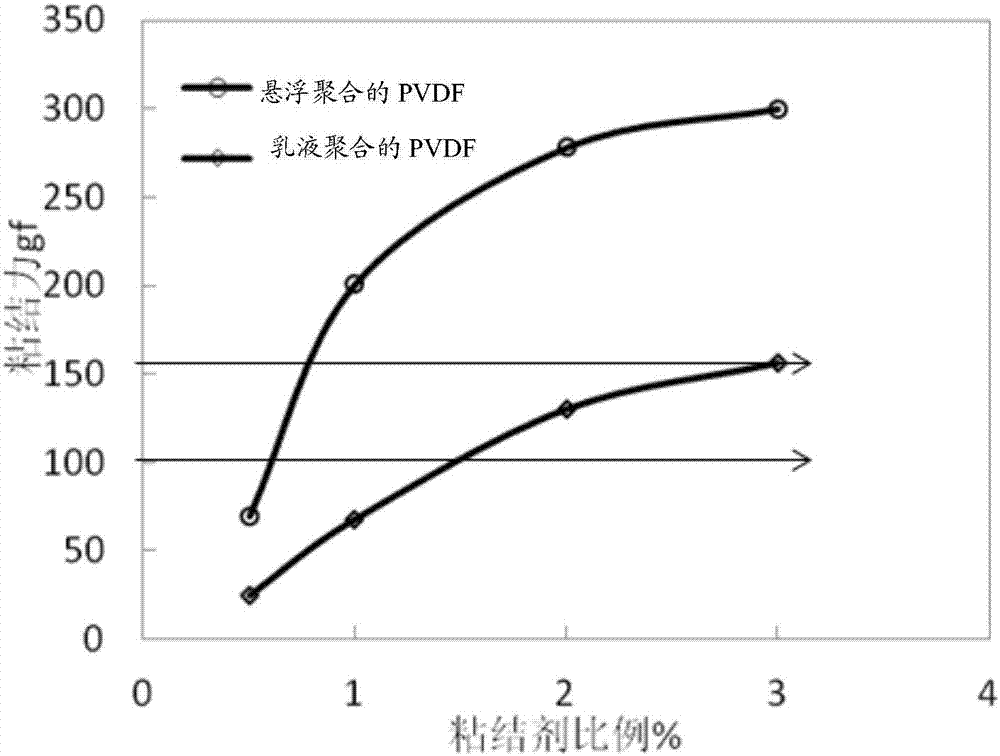

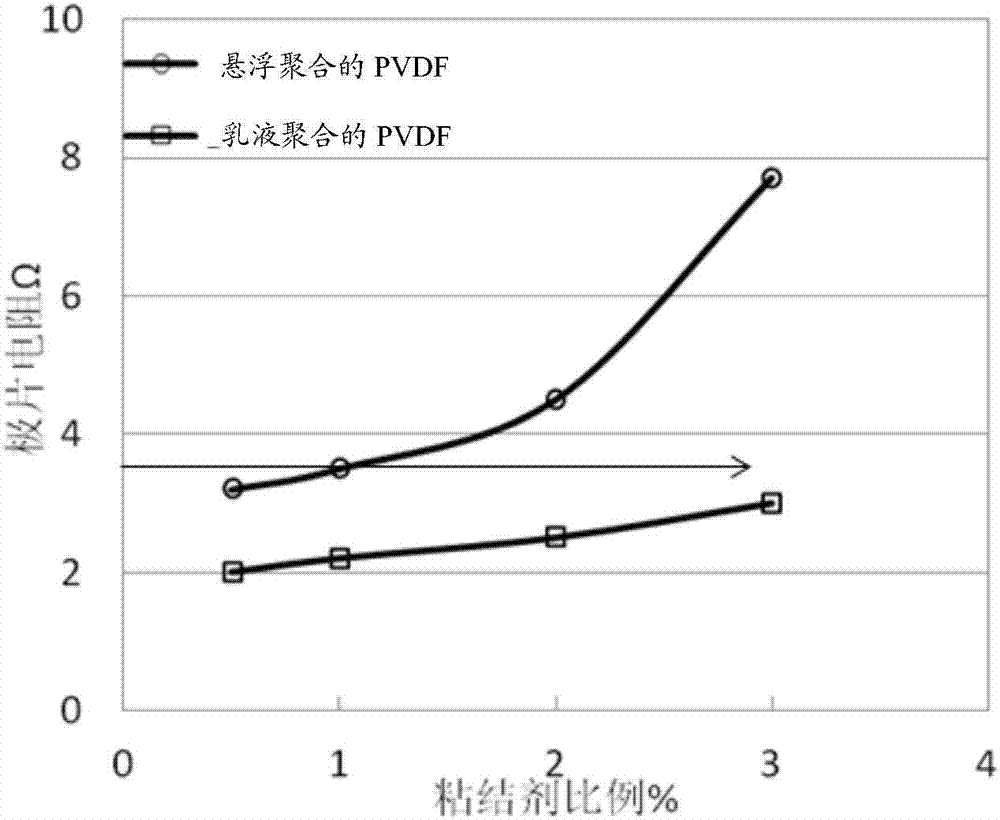

A high-nickel ternary material and positive electrode slurry technology, which is applied in the direction of electrical components, battery electrodes, structural parts, etc., can solve problems such as large rebound, poor adhesion, and difficult dispersion of slurry, so as to improve market application prospects, Significant significance in production practice, to solve the effect of wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In addition, the present invention also provides a method for preparing a composite binder for high-nickel ternary materials, which is used to produce the above-mentioned composite binder for high-nickel ternary materials provided by the present invention. The method specifically includes the following steps:

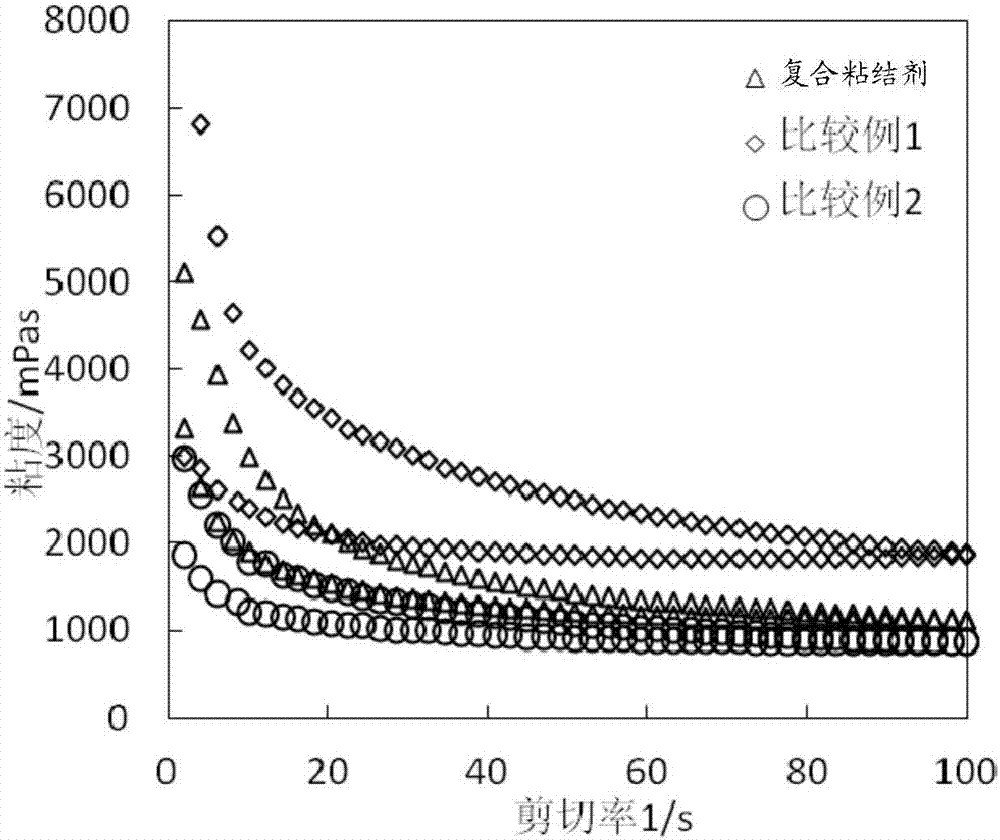

[0041] The first step: firstly, the easily dispersible emulsion polymerized PVDF is used as the solute, and nitrogen methylpyrrolidone NMP is used as the solvent, mixed according to the preset weight ratio, and fully stirred evenly, so that the obtained viscosity is between 800-1000 centipoise ( The PVDF glue of the emulsion polymerization of cp);

[0042] The second step: then carry out a preset number of (for example, 2 to 3) vacuuming operations on the obtained emulsion-polymerized PVDF glue to discharge the air bubbles in the emulsion-polymerized PVDF glue;

[0043] The third step: continue to add suspension polymerized PVDF to the emulsion polymerized PVDF glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com