Nano-Ni catalyst packed by resorcinarenes and preparation method thereof

A technology of calixarene and nano-nickel is applied in the field of meta-calixarene cladding nano-nickel particle catalyst and its preparation field, which can solve the problems of irregular shape of nano-particles, poor particle dispersibility, complicated catalytic process and the like, and achieve good dispersion performance. , good solubility and high cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 12.8g resorcinol and 21.4g laurylaldehyde in 115ml ethanol solution under stirring condition, add concentrated hydrochloric acid 18.5ml at 0 ℃, N 2 Under protection, the temperature was raised to 70 ° C for 10 hours, and then cooled to room temperature to obtain a yellow precipitate, which was filtered and washed with a large amount of water. After drying, methanol was recrystallized twice, and then recrystallized twice with n-hexane / acetone, and vacuum-dried to obtain Product 2,8,14,20-Tetrakis(undecyl)calix[4]resorcinolarene.

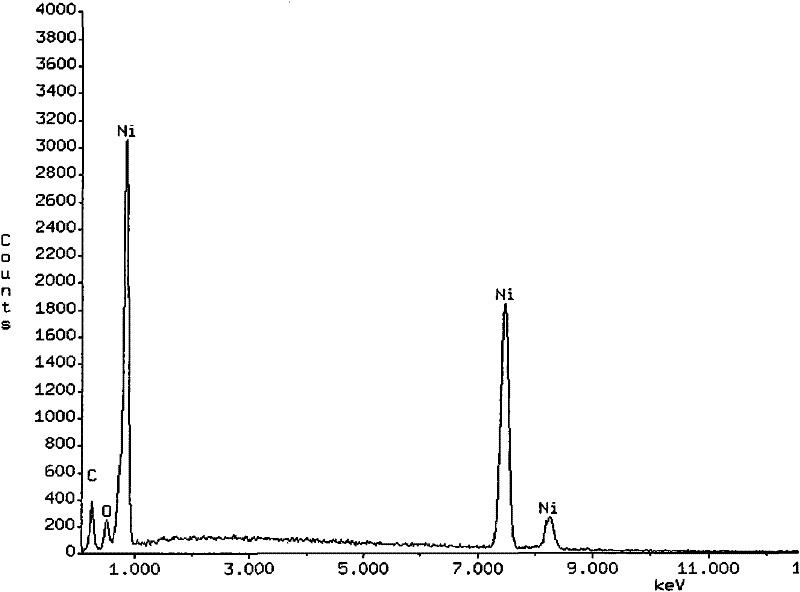

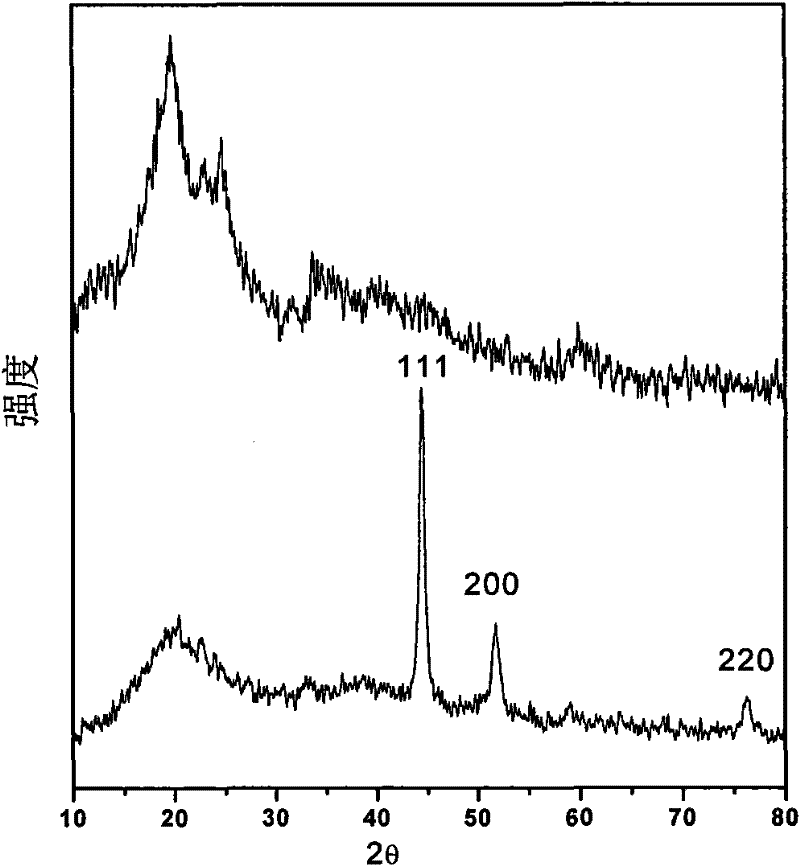

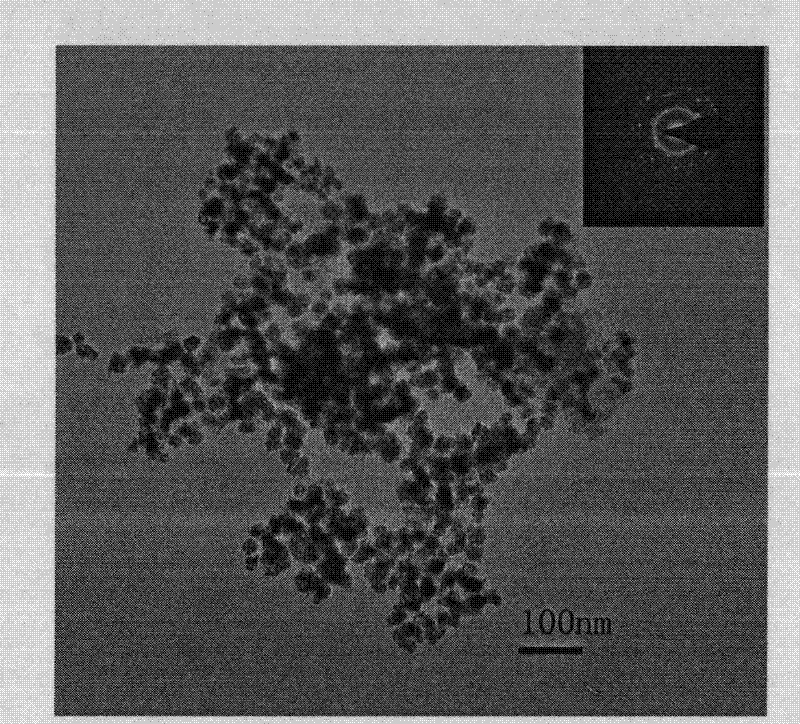

[0037] Take 2mmol nickel chloride (NiCl 2 ·6H 2 O) Dissolve in ethanol solution, ultrasonically disperse for 5min, prepare ethanol solution with nickel chloride concentration of 0.1mol / L, add a certain amount of 2,8,14,20-tetra (Undecyl) calix [4] resorcinol arene, stir and be heated to 50 ℃ and make it dissolve completely, add the sodium hydroxide aqueous solution of 0.8mol / L subsequently and adjust the solution pH to reach 10, add ...

Embodiment 2

[0042] 2,8,14,20-Tetrakis(undecyl)calix[4]resorcinolarene was prepared in the same manner as in Example 1.

[0043] Take 2mmol nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) be dissolved in ethanol solution, ultrasonic dispersion 5min, preparation nickel nitrate concentration is the ethanol solution of 0.1mol / L, add a certain amount of 2,8,14,20-tetra( Undecyl)calix[4]resorcinol aromatics, heated to 60°C while stirring to make it dissolve completely, then added 0.8mol / L aqueous sodium hydroxide solution to adjust the pH of the solution to 11, added 5ml 85wt% hydrazine hydrate Reduction was carried out, and the reaction was stopped after 0.5 hours. The obtained nano-nickel particles were centrifuged, washed three times with 30 ml of distilled water, washed three times with 30 ml of absolute ethanol, and vacuum-dried at 40° C. to obtain a metacalixarene inclusion nano-nickel catalyst. The particle size of the product is 30nm, and the crystal system is the same as that of Example 1. Th...

Embodiment 3

[0045] 2,8,14,20-Tetrakis(undecyl)calix[4]resorcinolarene was prepared in the same manner as in Example 1.

[0046] Take 2mmol nickel chloride (NiCl 2 ·6H 2 O) Dissolve in ethanol solution, ultrasonically disperse for 5min, prepare ethanol solution with nickel chloride concentration of 0.1mol / L, add a certain amount of 2,8,14,20-tetra (Undecyl)calix[4]resorcinol aromatics, heated to 60°C while stirring to make it dissolve completely, then added 1.0mol / L aqueous sodium hydroxide solution to adjust the pH of the solution to 10, added 5ml of 85wt% hydrated Hydrazine was reduced, and the reaction was stopped after 0.5 hours. The obtained nano-nickel particles were centrifuged, washed three times with 30 ml of distilled water, washed three times with 30 ml of absolute ethanol, and vacuum-dried at 40° C. to obtain a metacalixarene clathrate nano-nickel catalyst. The product sample also has high catalytic activity to the cracking reaction of JP-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com