Preparation method of copper-based Cu-Cu2O-CuO ternary composite core-shell material

A ternary compound, cu-cu2o-cuo technology, which is applied in the direction of catalyst activation/preparation, compounds of group 4/14 elements of the periodic table, chemical instruments and methods, etc., can solve the complex preparation process and unfavorable mass production , wide range of particle size distribution, etc., to achieve the effect of simple process route, wide particle size distribution and strong inclusiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

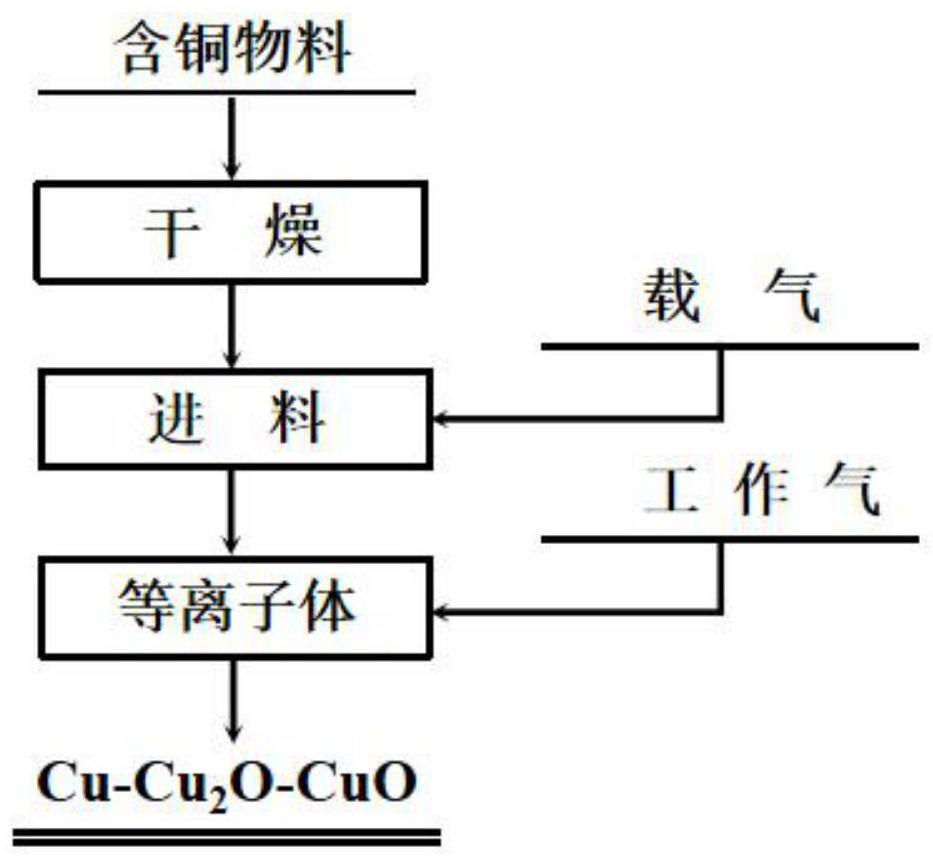

[0027] Embodiment 1: a kind of copper base Cu-Cu 2 The preparation method of O-CuO ternary composite core-shell material (see figure 1 ),Specific steps are as follows:

[0028] (1) Using high-purity copper powder with an average particle size of 500 μm as the raw material of the copper-containing powder, place the copper-containing powder at a temperature of 70° C. for 0.5 hours in vacuum;

[0029] (2) Argon gas is introduced into the DC thermal plasma system to exhaust the air, and Ar and O with a volume mixing ratio of 90:1 2 The mixed gas is the carrier gas, and the copper-containing powder raw material is sent into the thermal plasma torch at a feed rate of 0.1g / min through the carrier gas, where the power of the plasma generator is 14.0kW, and the working gas pressure of the carrier gas is 0.10MPa;

[0030] (3) Ar and O with a volume mixing ratio of 90:1 2 The mixed gas is hot plasma working gas. The working gas pressure of the hot plasma working gas is 0.10MPa. The co...

Embodiment 2

[0033] Embodiment 2: a kind of copper base Cu-Cu 2 The preparation method of O-CuO ternary composite core-shell material (see figure 1 ),Specific steps are as follows:

[0034] (1) Using high-purity copper powder with an average particle size of 0.1 μm as the raw material of the copper-containing powder, place the copper-containing powder at a temperature of 70° C. for 24 hours in vacuum;

[0035] (2) Argon gas is introduced into the DC thermal plasma system to exhaust the air, and the volume mixing ratio of Ar and O is 95:1. 2 The mixed gas is the carrier gas, and the copper-containing powder raw material is sent into the thermal plasma torch at a feed rate of 800g / min through the carrier gas, where the power of the plasma generator is 200kW, and the working gas pressure of the carrier gas is 0.60MPa;

[0036] (3) Ar and O with a volume mixing ratio of 95:1 2 The mixed gas is hot plasma working gas. The working gas pressure of the hot plasma working gas is 0.60MPa. The com...

Embodiment 3

[0039] Embodiment 3: a kind of copper base Cu-Cu 2 The preparation method of O-CuO ternary composite core-shell material (see figure 1 ),Specific steps are as follows:

[0040] (1) Dry mix industrial-grade copper powder and copper oxide powder in a roller mill for 8 hours to obtain a mixture with an average particle size of 3.7 μm as the raw material of copper-containing powder, and vacuum-dry the copper-containing powder at a temperature of 80°C for 6 hours , wherein the mass ratio of industrial grade copper powder and copper oxide powder is 1:1;

[0041] (2) Argon gas is introduced into the DC thermal plasma system to exhaust the air, and pure argon is used as the carrier gas, and the copper-containing powder raw material is fed into the thermal plasma torch at a feed rate of 4g / min through the carrier gas, and the plasma occurs The power of the device is 14.5kW, and the working gas pressure of the carrier gas is 0.16MPa;

[0042] (3) Use pure argon as the hot plasma work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com