Nanocellulose and preparation method thereof

A nanocellulose and cellulose technology, applied in the field of cellulose, can solve the problems of difficult recovery, long reaction time, low reaction efficiency, etc., and achieve the effects of reducing energy consumption and production cost, good redispersibility, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

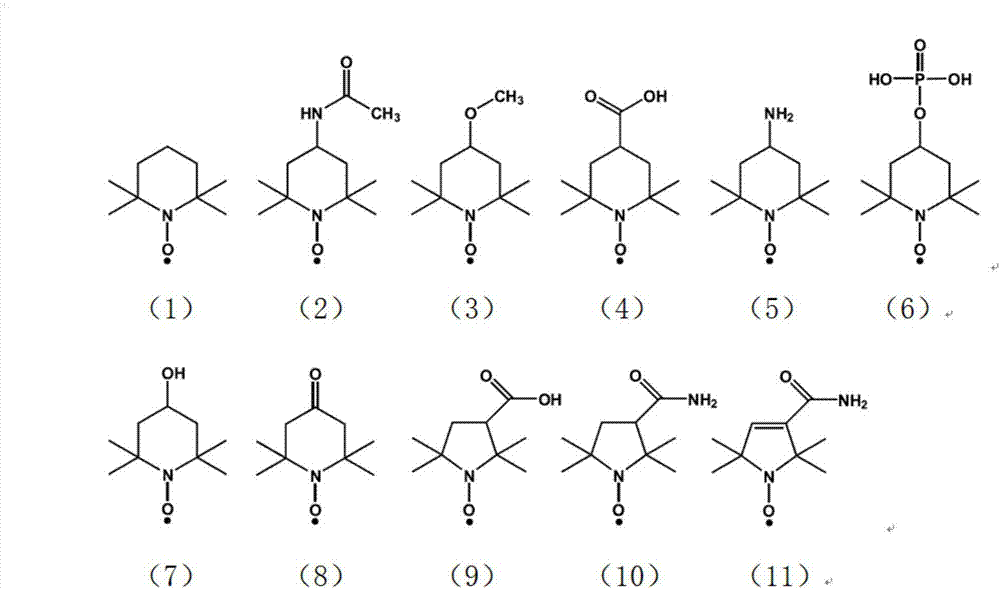

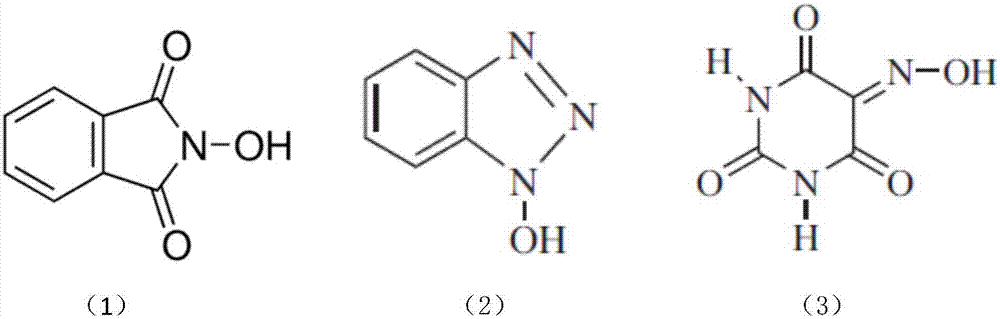

Embodiment 1

[0042] Add 500ml of distilled water to a 1L beaker, add 2.5mmol TEMPO (2,2,6,6-tetramethylpiperidine nitrogen oxide), 40mmol NaBr, 10mmolNaIO 4 Add to beaker and stir vigorously with a magnetic stirrer for 5 minutes. While the magnetic stirrer was continuously stirring, 5 g of commercially available microcrystalline cellulose was added into the beaker. After stirring evenly, 40 mmol of NaClO was slowly added. The stirring reaction was continued for 9 hours. During the reaction period, the pH value was adjusted once every 1.0 hour with 2M NaOH, so that the pH value of the reaction solution was maintained at about 10.5. After reacting for 9 hours, 5 mL of absolute ethanol was added to terminate the reaction, and the reaction time was 10 minutes. The whole experiment operation was carried out in the dark. The reaction solution was centrifuged at low speed for 2 minutes to precipitate the supernatant with absolute ethanol, and then centrifuged. The precipitate was washed twic...

Embodiment 2

[0044] Add 500ml of distilled water to a 1L beaker, add 2.5mmol TEMPO (2,2,6,6-tetramethylpiperidine nitrogen oxide), 40mmol NaBr, 10mmolNaIO 4 Add to beaker and stir vigorously with a magnetic stirrer for 5 minutes. While the magnetic stirrer was continuously stirring, 5 g of commercially available microcrystalline cellulose was added into the beaker. After stirring evenly, 40 mmol of NaClO was slowly added. The stirring reaction was continued for 10 hours. During the reaction period, the pH value was adjusted once every 1.0 hour with 2M NaOH, so that the pH value of the reaction solution was maintained at about 10.5. After reacting for 9 hours, 5 mL of absolute ethanol was added to terminate the reaction, and the reaction time was 10 minutes. The whole experiment operation was carried out in the dark. The reaction solution was centrifuged at low speed for 2 minutes, the supernatant was precipitated with absolute ethanol, and then centrifuged. The precipitate was washed ...

Embodiment 3

[0046] Except that vacuum drying time is 8 hours, all the other operation methods are the same as embodiment 1, can make as Figure 6 The sheet-like nanocellulose shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com