Resin compound, finished product of resin compound, and joint structure of finished product of resin compound

A technology of resin composition and molded products, which is applied in the direction of synthetic resin layered products, packaging items, layered products, etc. The effect of joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

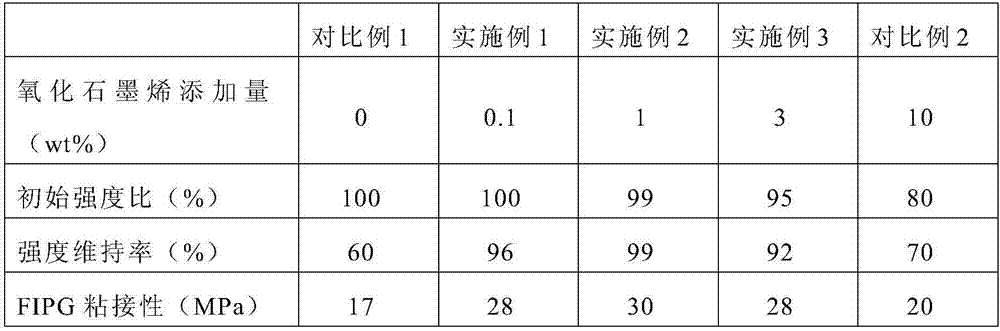

Embodiment 1

[0060] PA-6-GF30-01 (manufactured by Daicel Polymer Co., Ltd.), which is a polyamide 6 resin with 30% by mass of glass fiber added, using a 2-screw kneading extruder ("HK25D-41" manufactured by "Parker Polymer Co., Ltd.") ) and graphene oxide (manufactured by "Tokyo Chemical Industry Co., Ltd.", model: G0443, 0.1% by mass relative to the total mass of the resin composition) were melt-kneaded to form pellets.

Embodiment 2 and 3

[0062] Resins were produced in the same manner as in Example 1, except that the amount of graphene oxide added was changed to 1% by mass (Example 2) and 3% by mass (Example 3) relative to the total mass of the resin composition. Composition pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com