Polyurethane adhesive composition for shoes and preparation method thereof

A technology of polyurethane adhesives and compositions, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., which can solve problems such as not being suitable for shoemaking, harming the human body and the ecological environment, and being flammable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

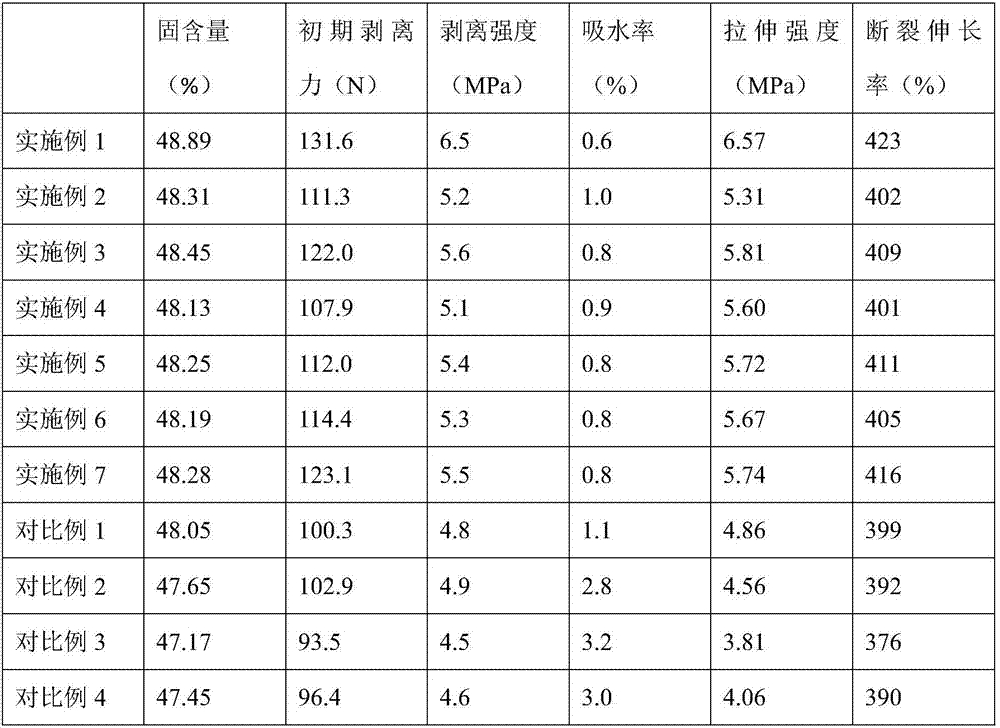

Examples

preparation example Construction

[0030] The preparation method of described organic clay modified epoxy resin is as follows:

[0031] (1) Add organoclay and N,N-dimethylacetamide into the reactor, heat up to 70°C, stir for 3 hours, add epoxy resin, keep warm at 70°C for 10 hours, add 70°C deionized water, Extract part of N,N-dimethylacetamide; the weight ratio of the organic clay to the N,N-dimethylacetamide is 1:3; the weight ratio of the organic clay to the epoxy resin is 0.16:1;

[0032](2) Debubble the extracted mixture in vacuum at 80°C for 6 hours, add glutaric anhydride and octadecyltrimethylammonium chloride, continue to remove bubbles in vacuum at 80°C for 2 hours, and then solidify at 80°C for 2 hours under normal pressure. Curing at 100°C for 1h and curing at 120°C for 5h to obtain the organoclay-modified epoxy resin; the weight ratio of the organoclay to the glutaric anhydride and the octadecyltrimethylammonium chloride is 1: 0.32:0.2.

[0033] The preparation method of described organic clay i...

Embodiment 1

[0064] The raw materials for preparing the polyurethane adhesive composition for shoes include: 24 parts of polyols, 26 parts of isocyanate compounds, 22 parts of chain extenders, 7 parts of modified epoxy resins, 6 parts of modified octa(aminophenyltrioxysilane), 5 parts of crosslinking agent, 60 parts of deionized water;

[0065] Wherein, the polyhydric alcohol is tripentaerythritol and rosin pentaerythritol ester, and the molar ratio of the tripentaerythritol to the rosin pentaerythritol ester is 1:2.3; the isocyanate compound is isophorone diisocyanate; the chain extender is 2,4-sodium diaminobenzenesulfonate and dimethylol propionic acid; the modified epoxy resin is an organoclay modified epoxy resin, and the organoclay is 2 grafted sodium dodecylsulfonate , a composite composition of 4,6-trihydroxybenzoic acid and attapulgite acrylic acid, the 2,4,6-trihydroxybenzoic acid grafted with sodium dodecylsulfonate in the organoclay and the acrylic acid The weight ratio of att...

Embodiment 2

[0081] The raw materials for preparing the polyurethane adhesive composition for shoes include: 24 parts of polyols, 26 parts of isocyanate compounds, 22 parts of chain extenders, 7 parts of modified epoxy resins, 6 parts of modified octa(aminophenyltrioxysilane), 5 parts of crosslinking agent, 60 parts of deionized water;

[0082] Wherein, the polyhydric alcohol is tripentaerythritol and rosin pentaerythritol ester, and the molar ratio of the tripentaerythritol to the rosin pentaerythritol ester is 1:1; the isocyanate compound is isophorone diisocyanate; the chain extender is 2,4-sodium diaminobenzenesulfonate and dimethylol propionic acid; the modified epoxy resin is an organoclay modified epoxy resin, and the organoclay is 2 grafted sodium dodecylsulfonate , a composite composition of 4,6-trihydroxybenzoic acid and attapulgite acrylic acid, the 2,4,6-trihydroxybenzoic acid grafted with sodium dodecylsulfonate in the organoclay and the acrylic acid The weight ratio of attap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com