Evaporator of riser for raw coke-oven gas from coke oven

A waste gas and evaporator technology, used in coke ovens, coke oven heating, indirect heat exchangers, etc., can solve problems such as increased sewage discharge, large ammonia water, consumption, etc., to avoid tar sticking and ensure safe operation. , the effect of uniform flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

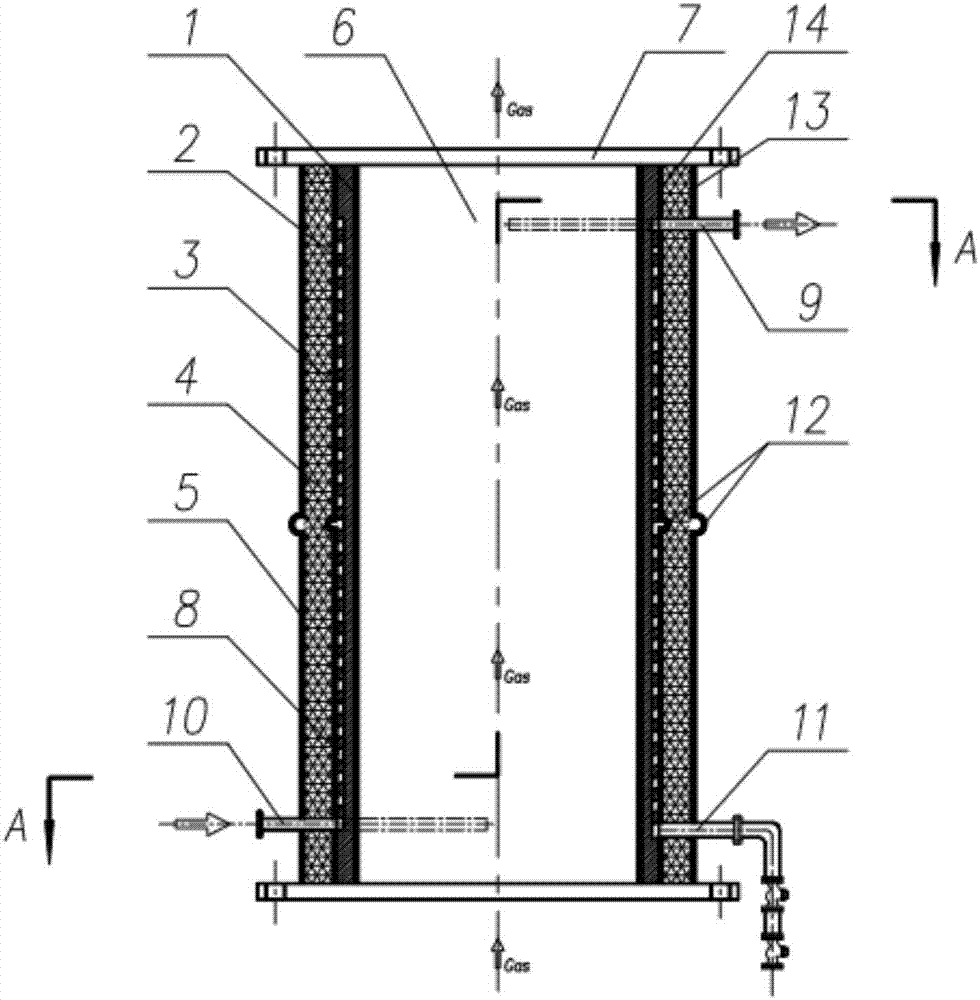

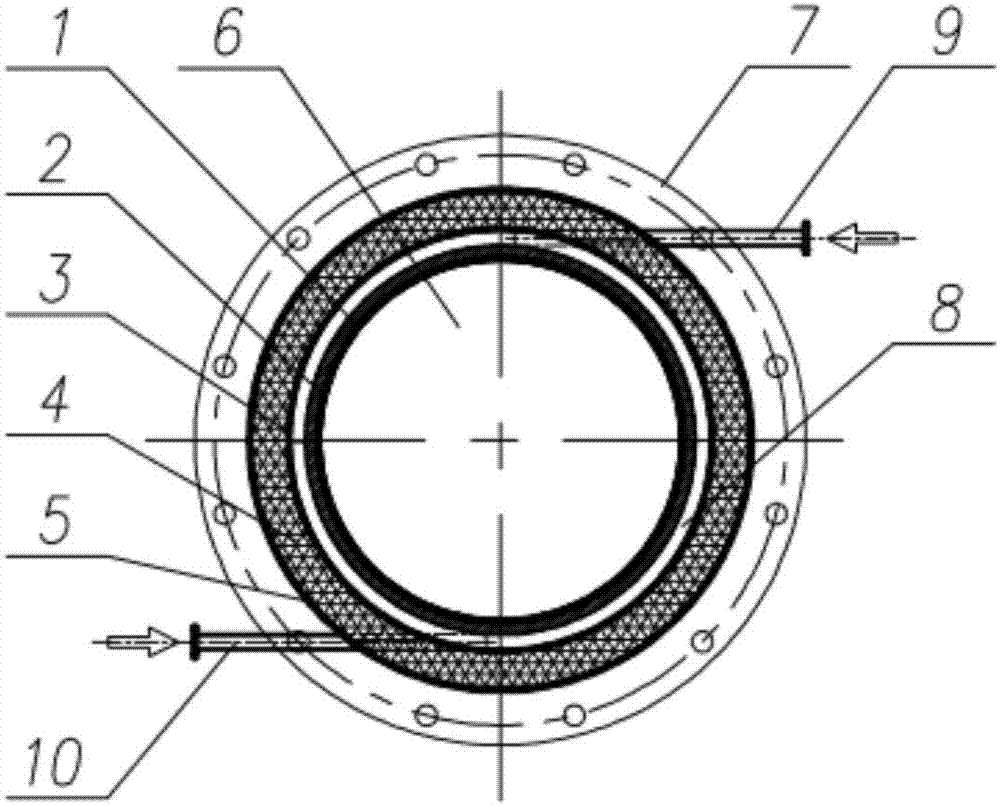

[0023] combine figure 1 , this embodiment provides a coke oven waste gas riser evaporator, which includes an inner tube 2, an inner sleeve 3, an insulating layer 4 and an outer jacket 5 that are sequentially arranged from the inside to the outside; wherein, the inner side of the inner tube is Waste gas channel 6, the upper and lower end surfaces of the inner pipe and the inner casing are respectively sealed with the flange 7, a steam-water channel 8 is formed between the inner pipe 2 and the inner casing 3, and the steam drum feed water is absorbed in the jacket and rises A water inlet pipe 10 is arranged at the bottom of the steam water channel for introducing cooling water to the steam water channel, and a water outlet pipe 9 is arranged at the top of the steam water channel; it also includes a temperature sensor, a control device and Inlet flow control valve;

[0024] The temperature sensor is arranged on the outer wall of the inner casing for the temperature of the outer ...

Embodiment 2

[0031] As a specific solution of Embodiment 1, the outer jacket is provided with a balance hole 13 and a temperature measurement hole 14 for placing a temperature sensor, and the temperature measurement thermocouple in the temperature sensor is in contact with the outer wall of the inner sleeve 3 .

[0032] The balance hole 13 in this embodiment can effectively balance the pressure difference caused by the temperature difference in the outer jacket 5; the temperature measurement hole 14 is provided on the outer side of the inner casing 3, and the water inlet can be controlled according to the temperature and flow rate change curve of the raw gas in the coking period of the coking chamber The flow ensures heat exchange efficiency.

Embodiment 3

[0034] As a further improvement of Embodiment 1, there are several groups of spiral grooves on the outer surface of the side wall of the inner tube, each of the spiral grooves has the same depth, and each of the spiral grooves forms a branch of a soda-water channel outside the inner tube; The end face of the side wall of the spiral groove is sealedly connected with the inner sleeve.

[0035] Preferably, the two adjacent sets of helical grooves are arranged at equal pitches.

[0036] In this embodiment, the coke oven waste gas riser tube evaporator adopts a unique spiral hole-slot steam-water channel structure. The outer wall of the inner tube is machined by a lathe, and the spiral groove is machined by turning and milling. There is no welding seam between the side walls of the spiral groove, so that the steam-water flow field in the jacket is evenly distributed, the heat exchange path is extended, the sufficient heat exchange between the media is ensured, the heat exchange eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com