Passivator for inhibiting trivalent chromium of zinc coating from being oxidized to hexavalent chromium

A technology of trivalent chromium and hexavalent chromium, which is applied in the direction of metal material coating process, etc., can solve the problems of human health and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

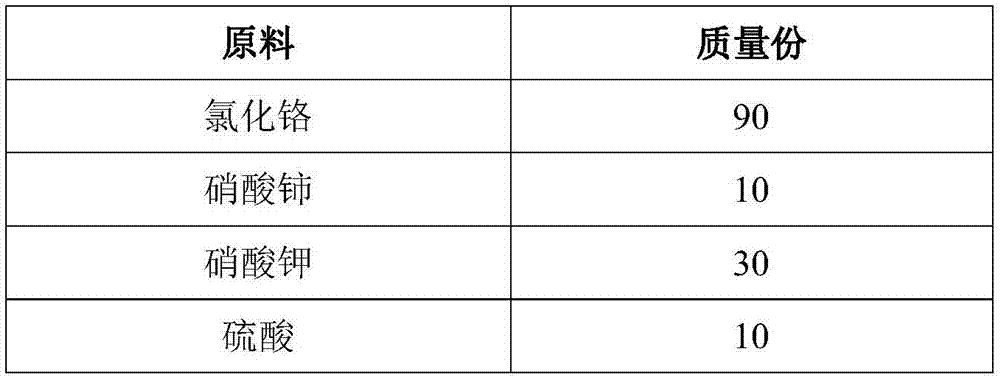

[0042] A kind of passivating agent that inhibits the oxidation of trivalent chromium to hexavalent chromium in the galvanized layer, its raw material composition is as shown in the following table:

[0043] Table 1 A raw material composition table for a passivating agent that inhibits the oxidation of trivalent chromium to hexavalent chromium in the galvanized layer

[0044] raw material

Embodiment 2

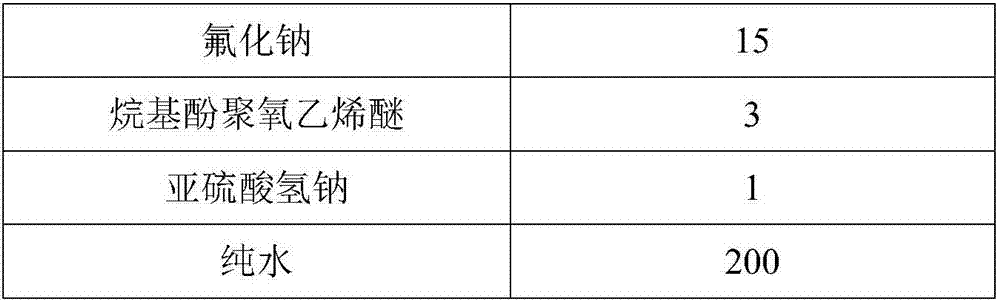

[0046] A kind of passivating agent that inhibits the oxidation of trivalent chromium to hexavalent chromium in the galvanized layer, its raw material composition is as shown in the following table:

[0047] Table 2 A kind of raw material composition list of the passivating agent that inhibits the oxidation of galvanized layer trivalent chromium to hexavalent chromium

[0048] raw material

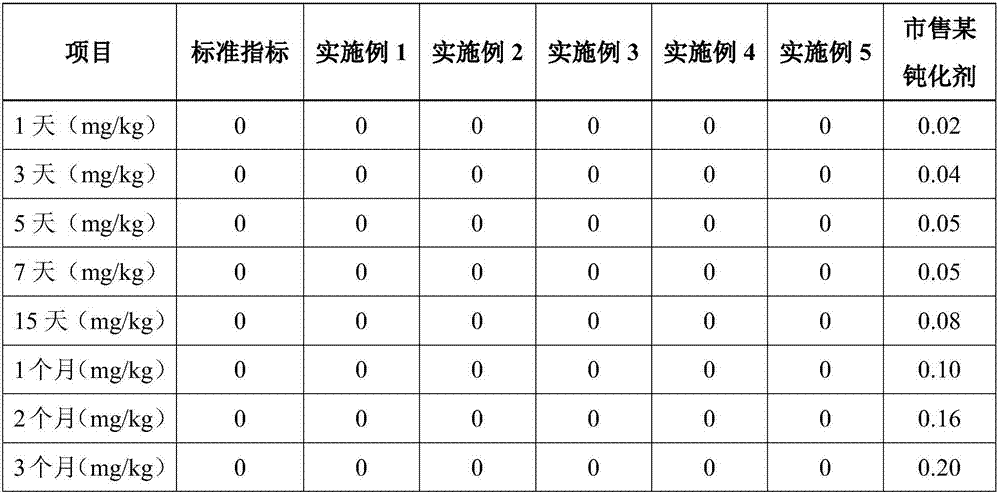

Embodiment 3

[0050] A kind of passivating agent that inhibits the oxidation of trivalent chromium to hexavalent chromium in the galvanized layer, its raw material composition is as shown in the following table:

[0051] Table 3 A kind of raw material composition table of the passivating agent that inhibits the oxidation of galvanized layer trivalent chromium to hexavalent chromium

[0052]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com