A boiler flue gas waste heat recovery device

A technology of waste heat recovery device and boiler flue gas, which is applied in the field of waste heat recovery device and boiler flue gas waste heat recovery device, can solve the problems of high system complexity, achieve the effects of improving matching characteristics, increasing temperature and humidity levels, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

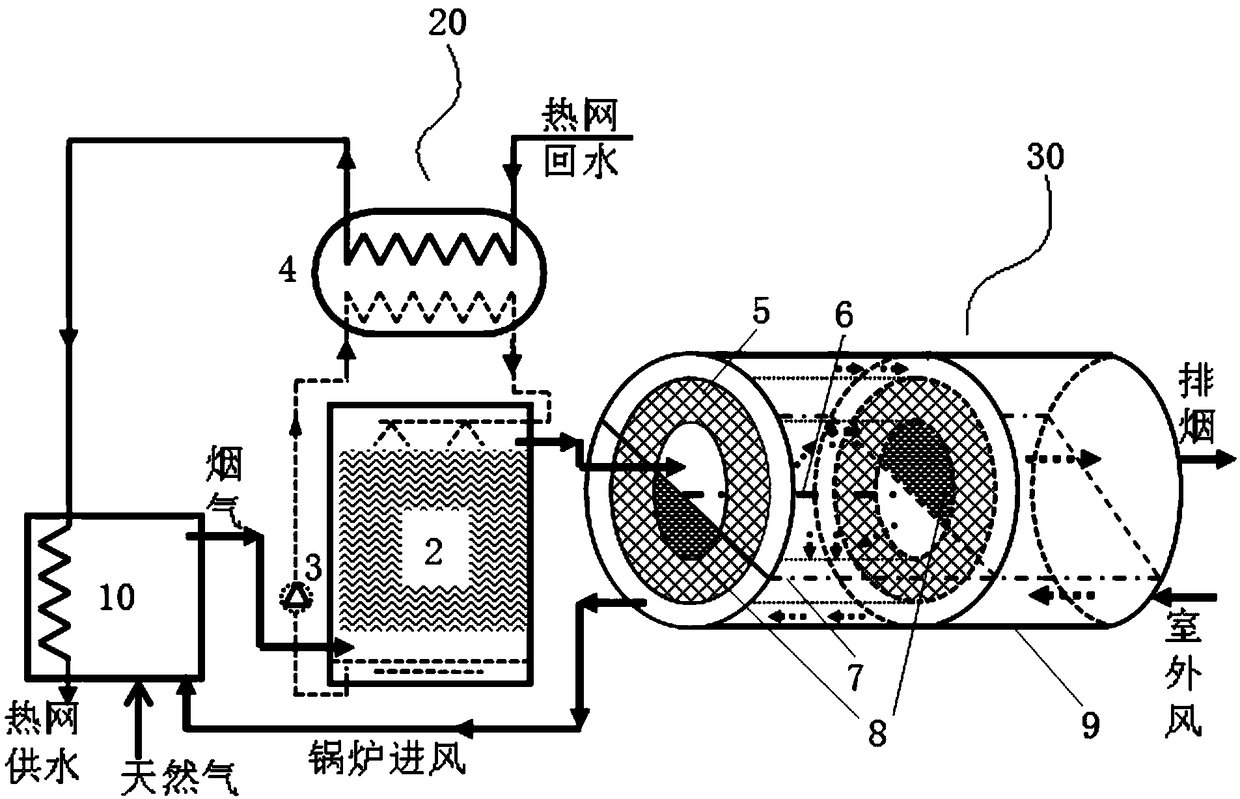

[0018] figure 1 A boiler flue gas waste heat recovery device using a solid moisture absorbent according to Embodiment 1 of the present invention is shown. The device includes a gas boiler 10 , a direct spray type flue gas heat recovery unit 20 and a solid moisture absorbent heat recovery unit 30 .

[0019] Wherein, the direct spray flue gas heat recovery unit 20 includes a flue gas-water spray tower 2 , a circulating water pump 3 and a water-water heat exchanger 4 . The solution outlet at the bottom of the flue gas-water spray tower 2 is connected to the spray inlet of the flue gas-water spray tower 2 through the circulating water pump 3 and the water-water heat exchanger 4, and the heat exchange end of the water-water heat exchanger 4 enters the The water pipe is connected to the return water of the heating network, and the water outlet pipe is connected to the heating network for water supply after passing through the gas boiler 10 .

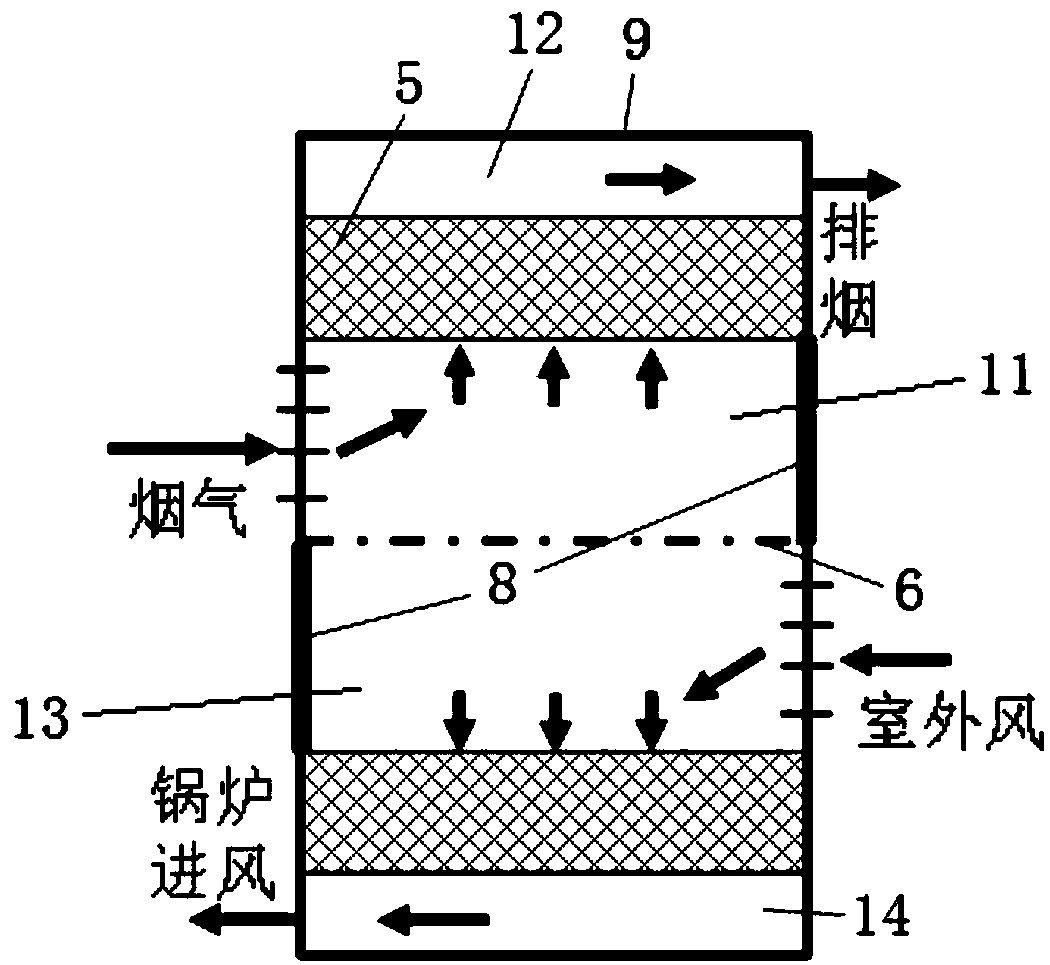

[0020] Such as figure 1 , figure 2 ...

Embodiment 2

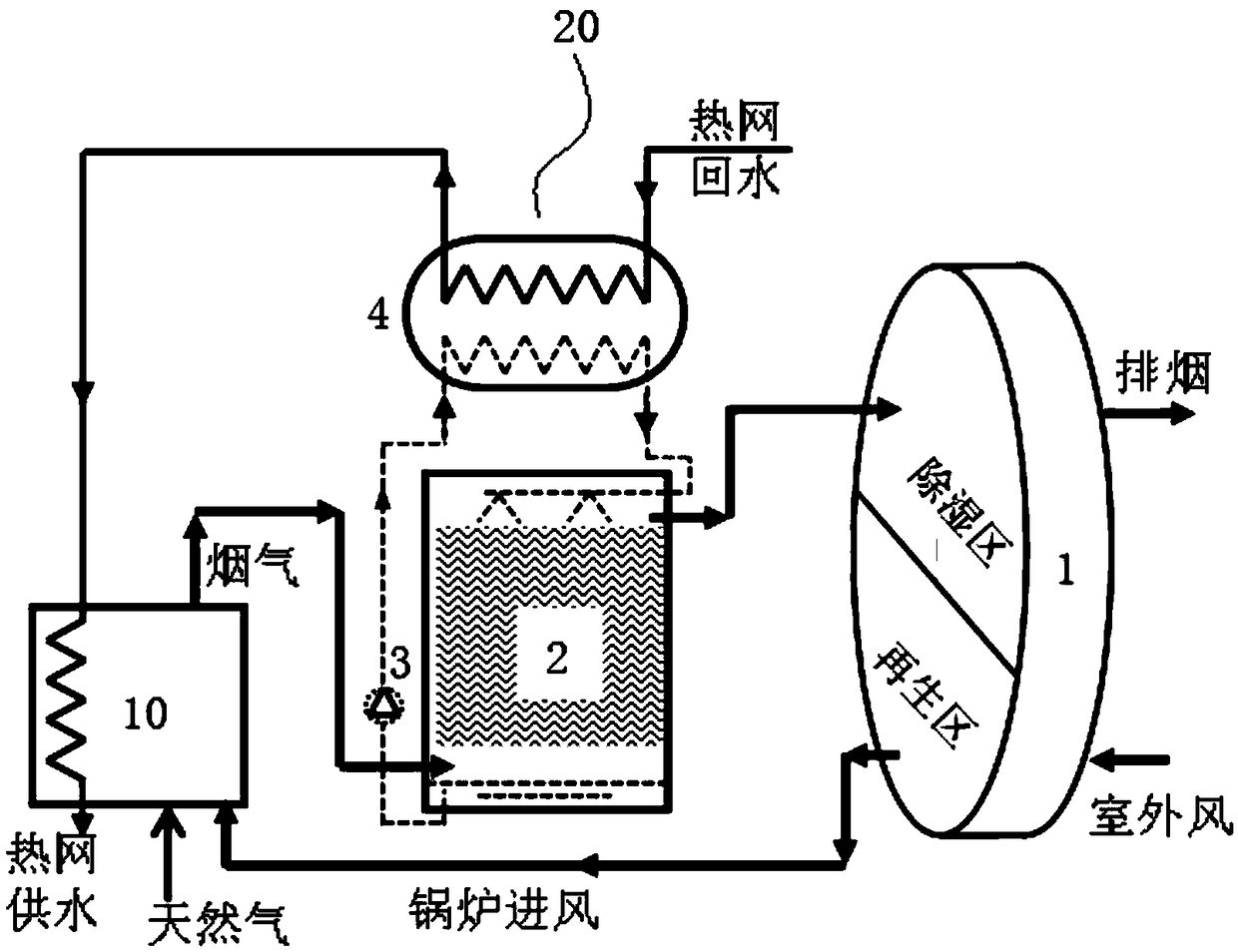

[0030] image 3 The boiler flue gas waste heat recovery device provided according to Embodiment 2 of the present invention using a solid moisture absorbent runner is shown. Compared with the boiler flue gas waste heat recovery device provided in Embodiment 1, the difference between this flue gas waste heat recovery device is only that: The solid moisture absorbent runner 1 realizes the total heat recovery process between the flue gas and the outdoor wind, that is, the flue gas flowing out from the top of the flue gas-water spray tower 2 directly flows through the dehumidification area of the solid moisture absorbent runner 1, and The solid hygroscopic agent performs heat and mass exchange, and the heat and moisture in the flue gas are absorbed by the solid hygroscopic agent to become smoke exhaust; the outdoor wind flows through the regeneration area of the solid hygroscopic agent runner 1, and performs heat and mass exchange with the solid hygroscopic agent. , after being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com