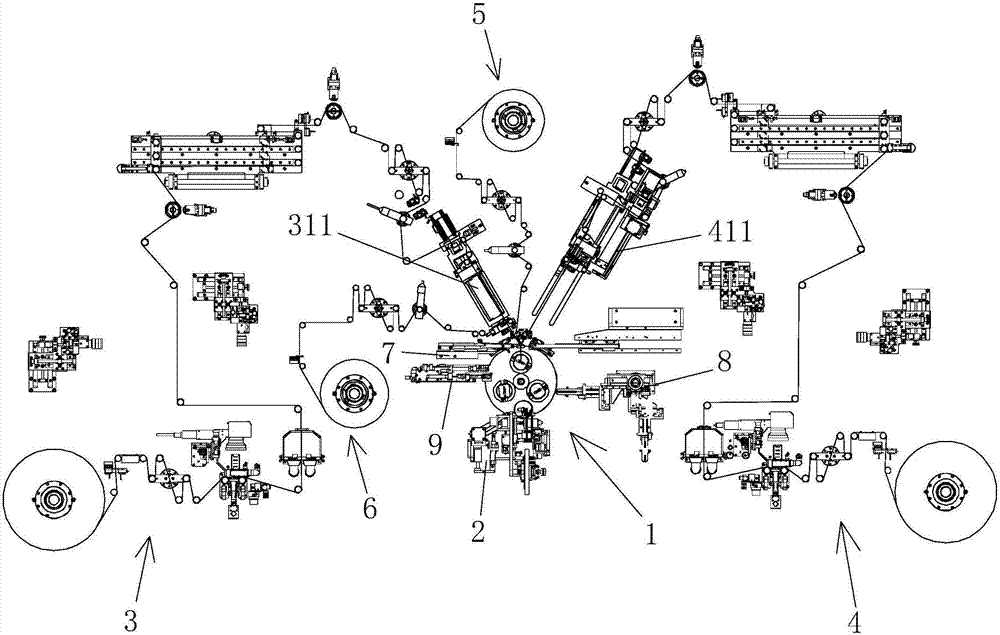

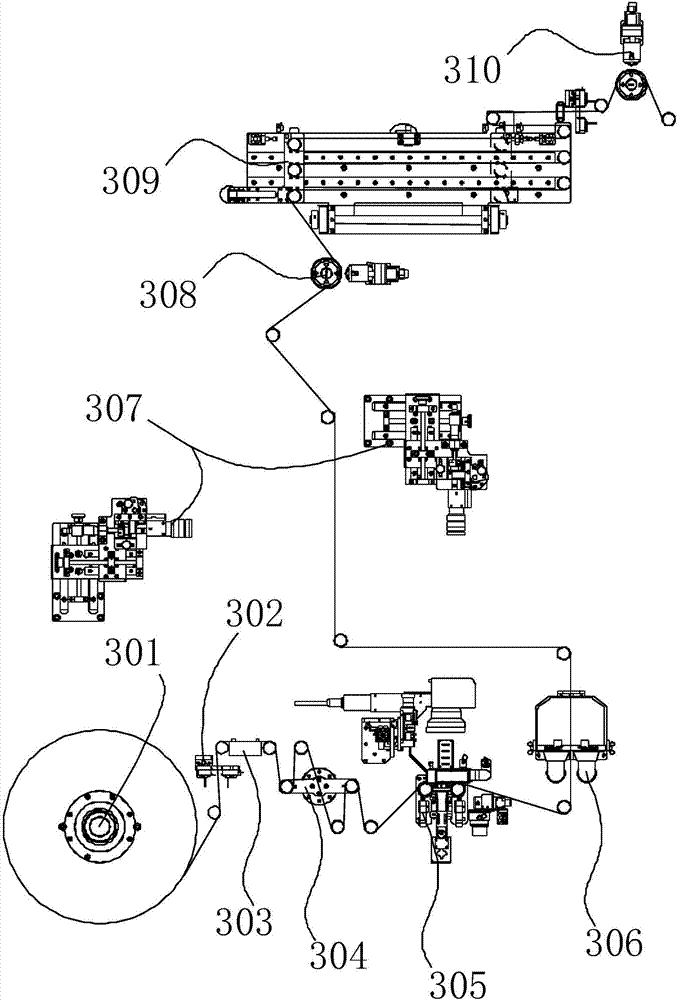

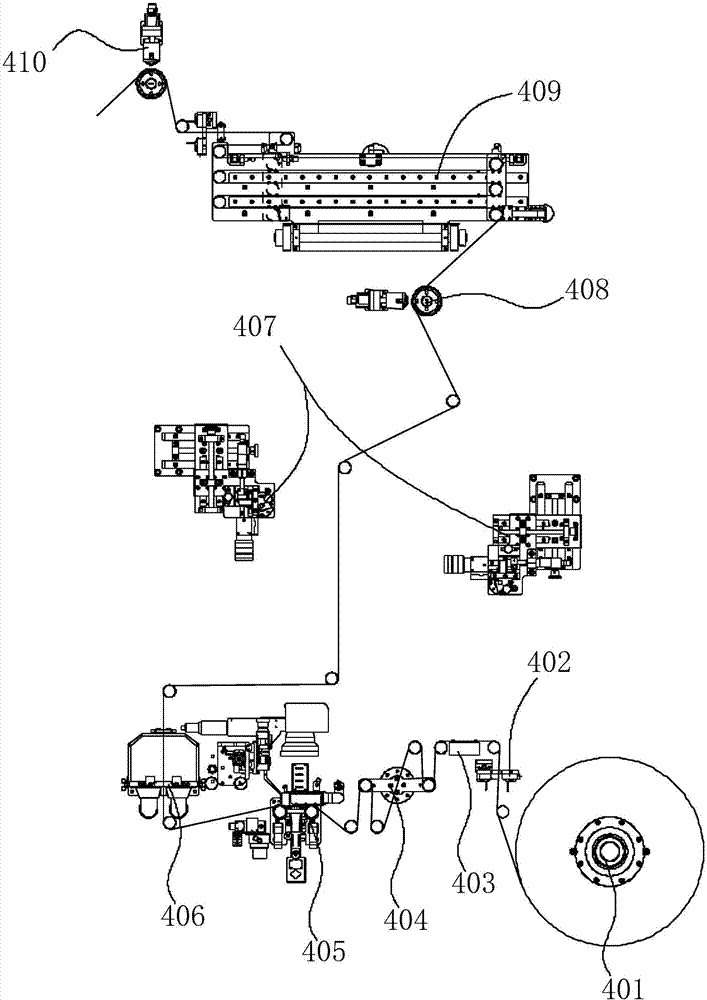

Lithium ion battery core cladding winding machine for laser film production

A lithium-ion battery and winding machine technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of battery heating or fire, large internal resistance of welding positions, and low production efficiency, so as to improve the heating problem and occupy The effect of small area and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings. The present application can be implemented in many different forms, and is not limited to the implementation manner described in this embodiment. The purpose of providing the following specific embodiments is to facilitate a clearer and more thorough understanding of the disclosure of the present application, wherein the words indicating orientation such as up, down, left, and right are only for the positions of the structures shown in the corresponding drawings.

[0036] However, those skilled in the art may recognize that description of one or more of the specific details may be omitted, or other methods, components or materials may also be used. In some instances, some implementations were not described or described in detail.

[0037] In addition, the technical features and technical solutions described herein can also be com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com