Mold punch and processing method thereof

A technology of mold punches and processing methods, which is applied in the field of mold punches, can solve the problems of easy wear and short life of mold core parts, and achieve the effects of easy processing and molding, improved service life, and guaranteed dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0042] A mold punch disclosed by the present invention and its processing method adopt ceramic material as the processing material of the mold punch, combined with a new processing technology, thereby processing a mold punch with high wear resistance, high processing precision and simple structure , especially in the field of stamping dies.

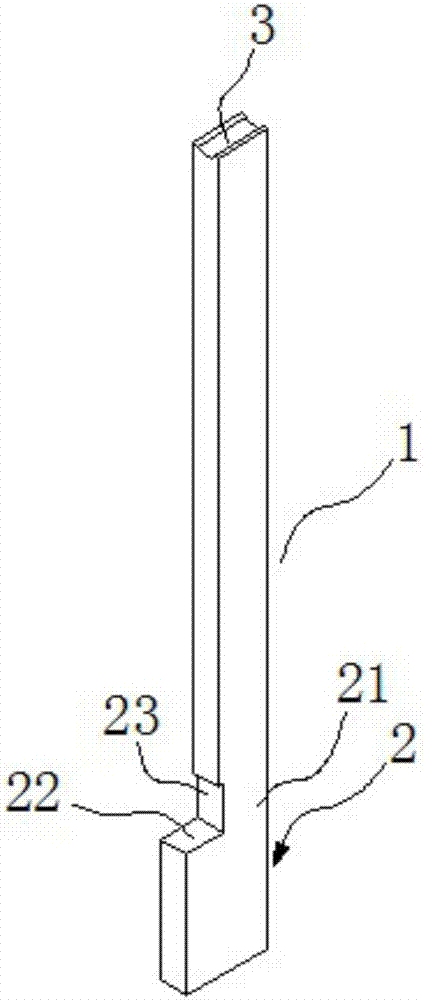

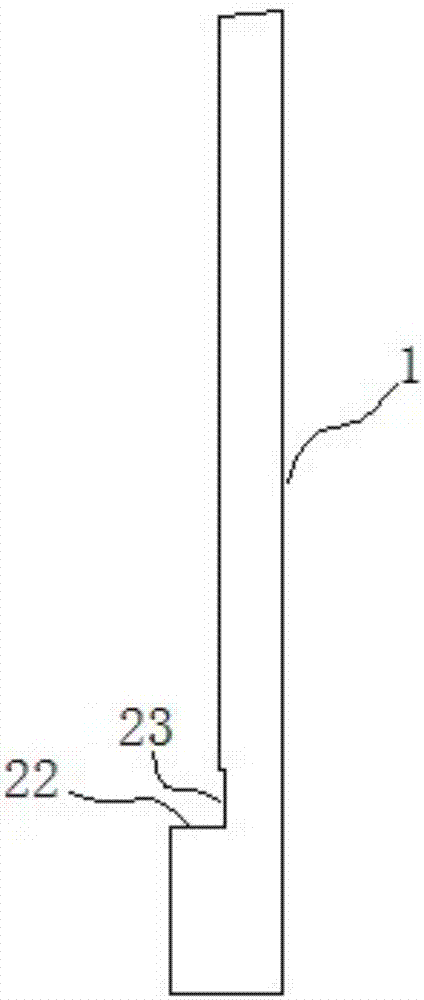

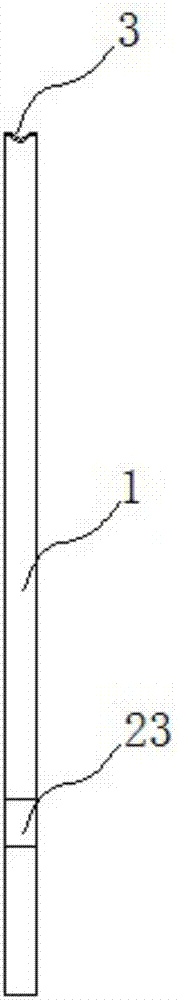

[0043] to combine Figure 1 ~ Figure 3 As shown, a die punch disclosed by the present invention includes a punch body 1 and a mounting part 2, both of which are integrally formed, and the mounting part 2 is used to fix the punch body 1 to other equipment for processing or work etc.

[0044] Specifically, in this embodiment, the punch body 1 as a whole has a slender rod body structure, and the rod body is in the shape of a cuboid. During specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com