Preparation process of high-purity corundum

A preparation process, corundum technology, which is applied in the field of high-purity corundum preparation process, can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effects of improving production efficiency, strong economic practicability, and realizing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

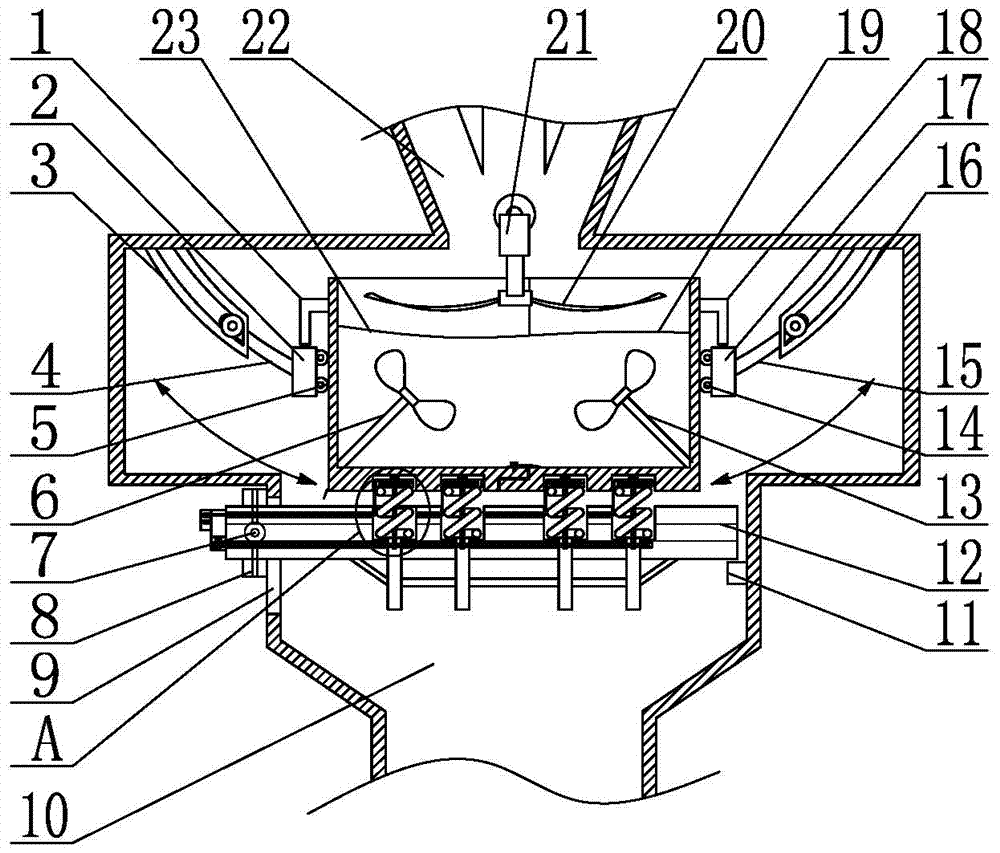

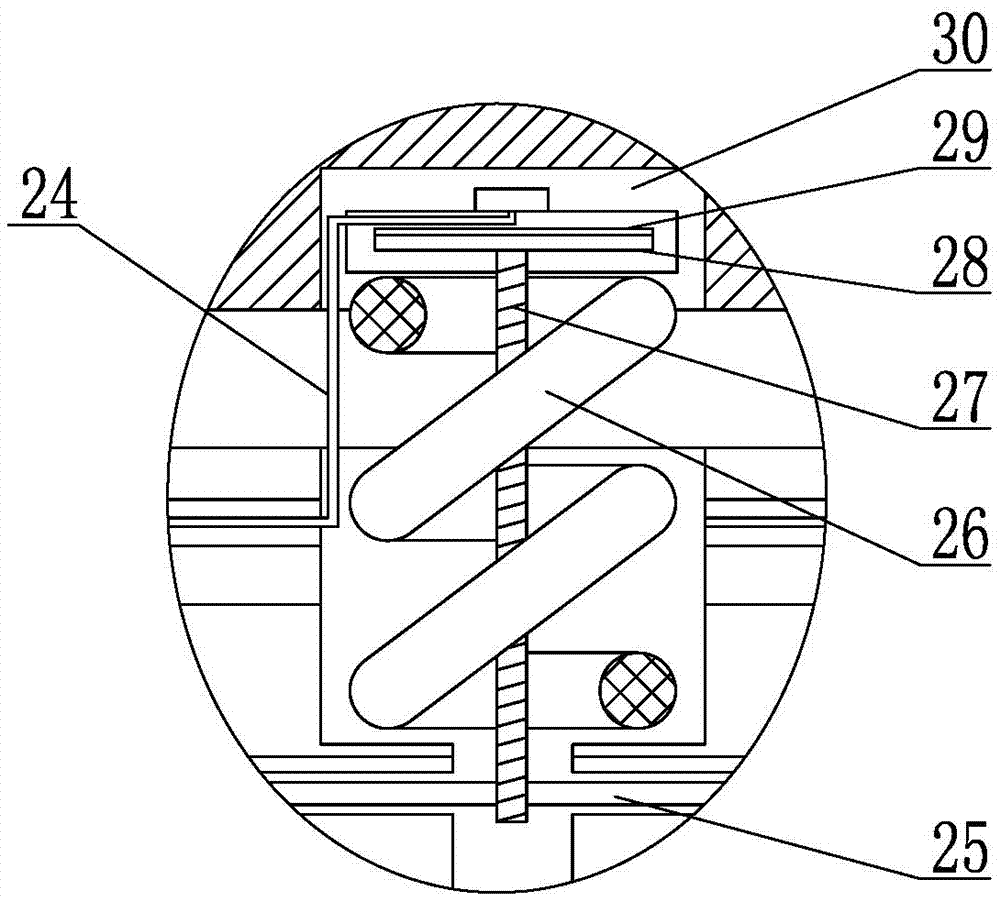

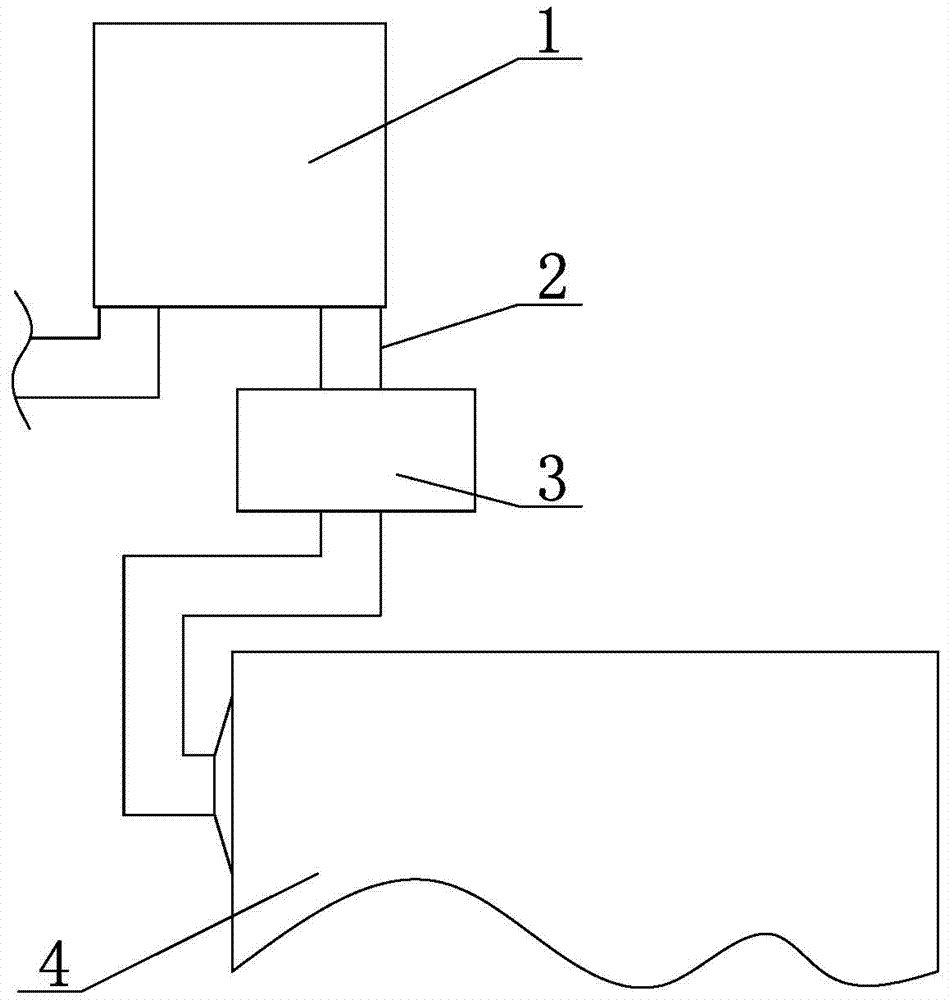

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] A preparation process for high-purity corundum, comprising the steps of:

[0053] (1) Add alumina monohydrate powder into the mixed solution of hydrochloric acid and water, the molar ratio of alumina monohydrate: hydrochloric acid: water is 1:10:60, and stir for 10 hours to obtain a suspension;

[0054] (2) Manganese oxide is added to the resulting suspension, the molar ratio of aluminum oxide monohydrate and manganese oxide in the suspension is 1:100, and a wet gel is obtained after stirring for 6-8 hours;

[0055] (3) The obtained wet gel is dried at 100-180°C for 12-24 hours to obtain a xerogel, which is pulverized to screen out 50-70 mesh particles;

[0056] (4) Mix the obtained xerogel particles and composite functional additives in a mixer, then put them into an electric arc furnace and gradually heat up at 600-800°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com