Fourfold pipe stratum decompression type double-liquor rotary spraying construction method

A construction method, the technology of four-fold pipe, applied in the direction of soil protection, foundation structure engineering, sheet pile wall, etc., can solve the problems such as difficult rotary grouting solidification, difficult to generate large diameter rotary grouting piles, etc., to achieve strong economic practicability, Simple and reliable construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

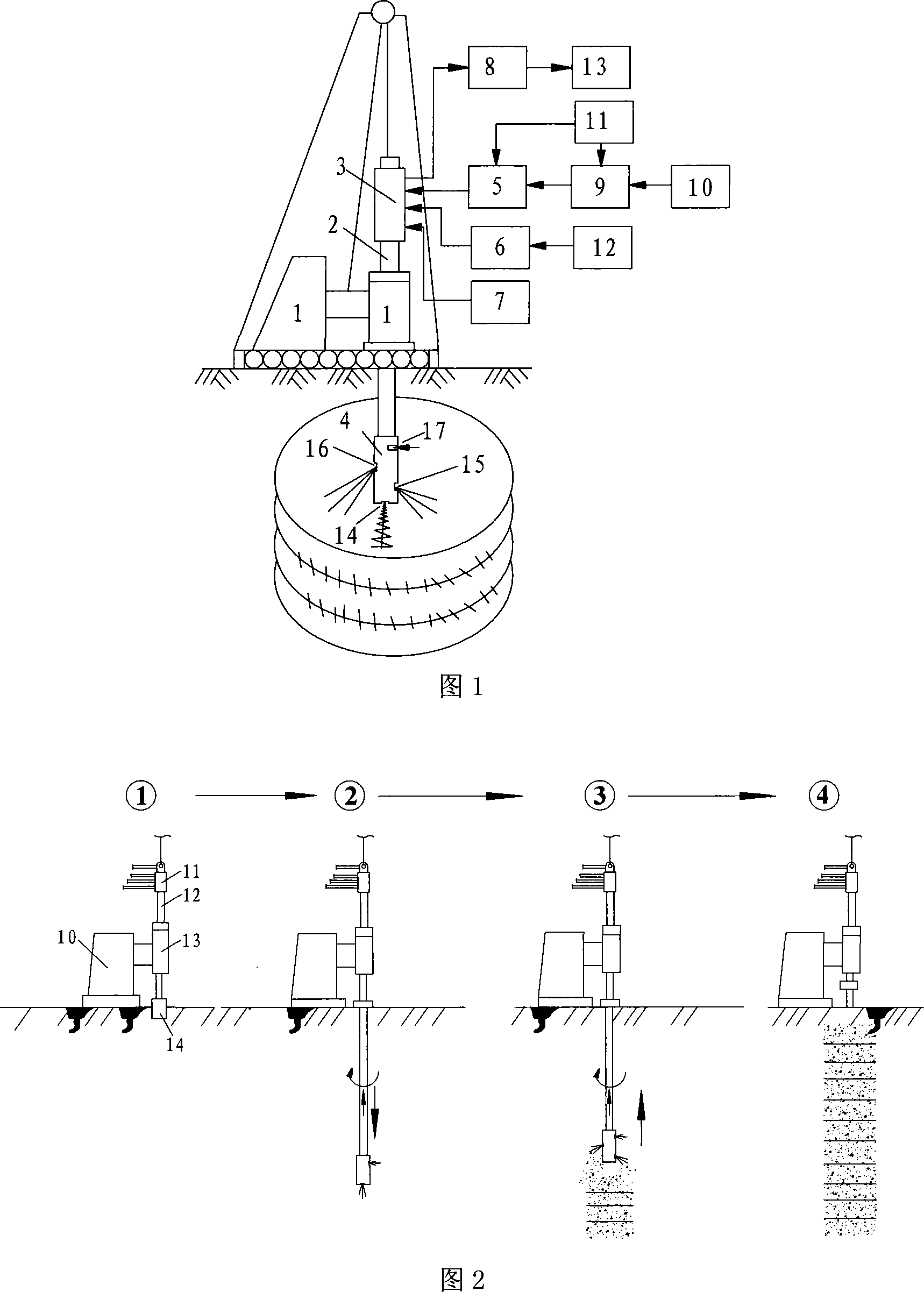

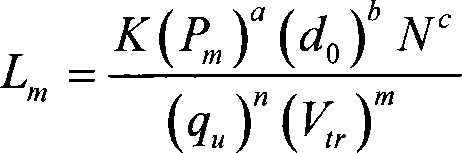

[0028] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

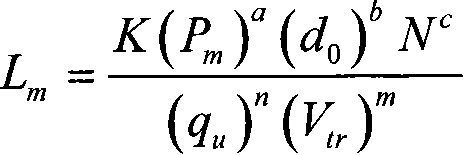

[0029] The embodiment is the construction of the foundation pit foundation reinforcement of a subway station in Seoul, South Korea. The geological condition of the construction site is a diluvial layer, and the layers accumulated sequentially from top to bottom are: the first layer, with a depth of 0-3m, is clayey silt , the water content is 26-48%, and the N value is 5-10; the depth of the second layer is 3-7.0m, which is gravel sandy soil, the water content is 17-28%, and the N value is 10-30; Layer depth is 7.0-10.5m, silty clay, water content 29-36%, N value 5-10; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com