Polypropylene sphere bubble material and preparation method thereof

A technology of polypropylene and bulbs, applied in the field of new modified polypropylene materials, which can solve the problems of high raw material cost, easy bending, and low rigidity, and achieve the effects of light weight, good toughness, and low rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

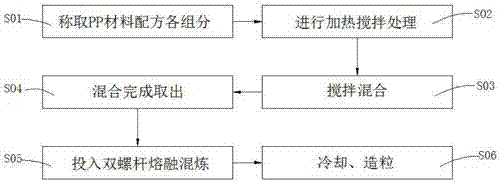

[0036] In combination with the embodiments of the present invention, a method for preparing a polypropylene bulb material is provided, and the method includes the following steps.

[0037] S1. Weigh each basic component of the formula: Weigh each component according to the formula of the polypropylene bulb material, combined with different weight percentages.

[0038] S2. Prepare the mixed material.

[0039] S21. Put the polypropylene raw material weighed in step S1 into a high-speed mixer, add a small amount of white oil at the same time, heat and stir for 3 minutes, and the space temperature rises to 60°C, and continue stirring.

[0040] S22. The transparent nucleating agent, stiffening nucleating agent, fluorescent whitening agent, ethylene bis stearamide, antioxidant and ultraviolet absorber Uv-531 taken in step S1 are successively added to step S02. The high-speed mixer is used to mix and stir with the polypropylene raw material and fully react, and the stirring time is ...

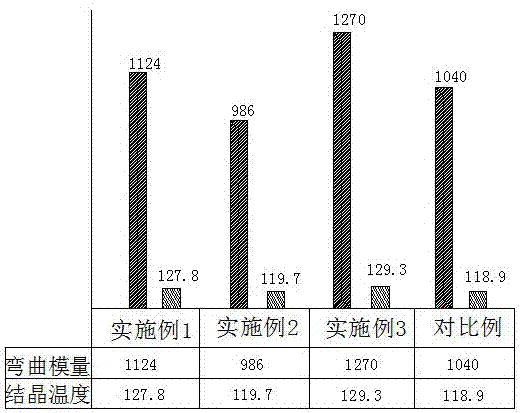

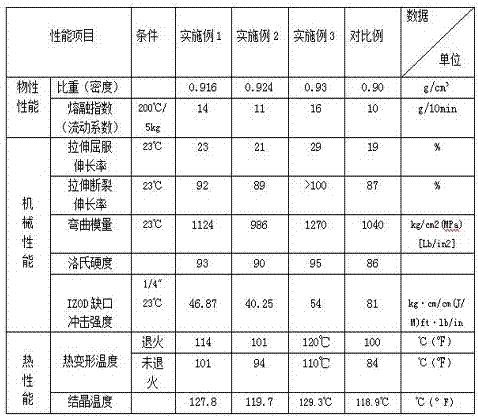

Embodiment 1

[0047] A kind of polypropylene bulb material, according to the formula component of following percentage by weight:

[0048] Polypropylene 96.65%

[0049] Transparent nucleating agent WBQ-88 0.3%

[0050] Rigid nucleating agent WNA-108 0.3%

[0051] Silicone Light Diffuser 1%

[0052] Fluorescent whitening agent OB-1 0.03%

[0053] Ethylene bis stearamide EBS-SF 0.97%

[0054] Antioxidant 1010 0.4%

[0055] Antioxidant 168 0.3%

[0056] Ultraviolet absorber Uv-531 0.02%

[0057] White Diffuser 0.03%.

[0058] This embodiment is prepared according to the formula of the above-mentioned polypropylene bulb material, and the following technical steps are taken.

[0059] S01. Weigh each basic component according to the weight percentage in the formula, and dry the symmetrically obtained basic components for future use in the subsequent process. Specifically, a drying machine can be used for uniform drying.

[0060] S02. Put the polypropylene raw material dried in step S01 i...

Embodiment 2

[0066] A kind of polypropylene bulb material, according to the formula component of following percentage by weight:

[0067] Polypropylene 98.195%

[0068] Transparent nucleating agent WBQ-88 0.1%

[0069] Rigid nucleating agent WNA-108 0.1%

[0070] Silicone Light Diffuser 1%

[0071] Fluorescent whitening agent OB-1 0.03%

[0072] Ethylene bis stearamide EBS-SF 0.5%

[0073] Antioxidant 1010 0.005%

[0074] Antioxidant 168 0.02%

[0075] Ultraviolet absorber Uv-531 0.02%

[0076] White Diffuser 0.03%.

[0077] This embodiment is prepared according to the formula of the above-mentioned polypropylene bulb material, and the following technical steps are taken.

[0078] S01. Weigh each basic component according to the weight percentage in the formula, and dry the symmetrically obtained basic components for future use in the subsequent process. Specifically, a drying machine can be used for uniform drying.

[0079] S02. Put the polypropylene raw material dried in step S0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com