Biomass gasification-circulating fluidized bed boiler combined power generation system and working method thereof

A circulating fluidized bed and combined power generation technology, which is applied in gasification process, chemical industry, combined combustion mitigation, etc., can solve problems such as low power generation efficiency, limited power generation scale, and technical difficulties, so as to improve energy utilization efficiency and enhance Adaptability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

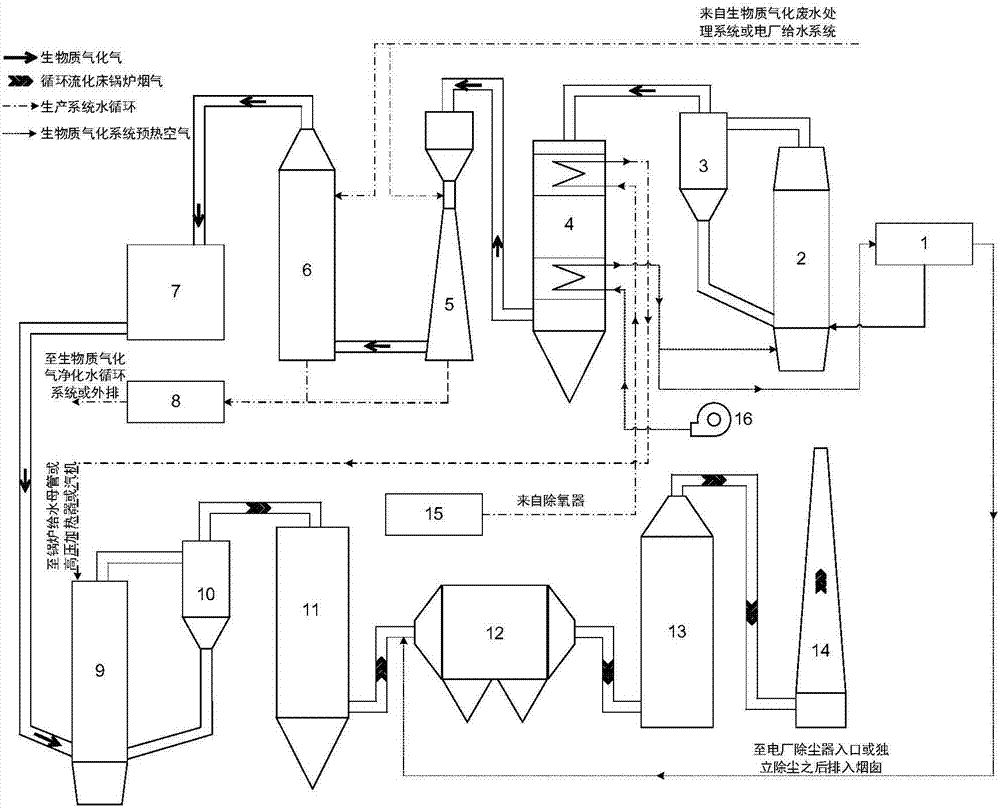

[0021] The invention is a biomass gasification-circulating fluidized bed boiler combined power generation system, with figure 1 The system is demonstrated. This system is divided into biomass gasification production system, circulating fluidized bed boiler production system and waste heat recovery and utilization system. The following will first give a comprehensive description of the system, and then describe the specific parameters and details of each system in detail.

[0022] Comprehensive description of biomass gasification-circulating fluidized bed boiler combined power generation system:

[0023]After the biomass is ground in the biomass grinding equipment 1, it enters the biomass circulating fluidized bed gasifier 2 for gasification to generate biomass gasification gas; the biomass gasification gas enters the biomass circulating fluidized bed The gasifier separator 3 separates the solid material and returns it to the biomass circulating fluidized bed gasifier 2; when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com