Casting equipment for the production of cast webs of homogenized tobacco material

A homogenization and casting technology, applied in tobacco, tobacco processing, tobacco preparation, etc., can solve problems such as web rupture, web tearing, machine stop, etc., achieve uniform deposition, reduce defects, and improve circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

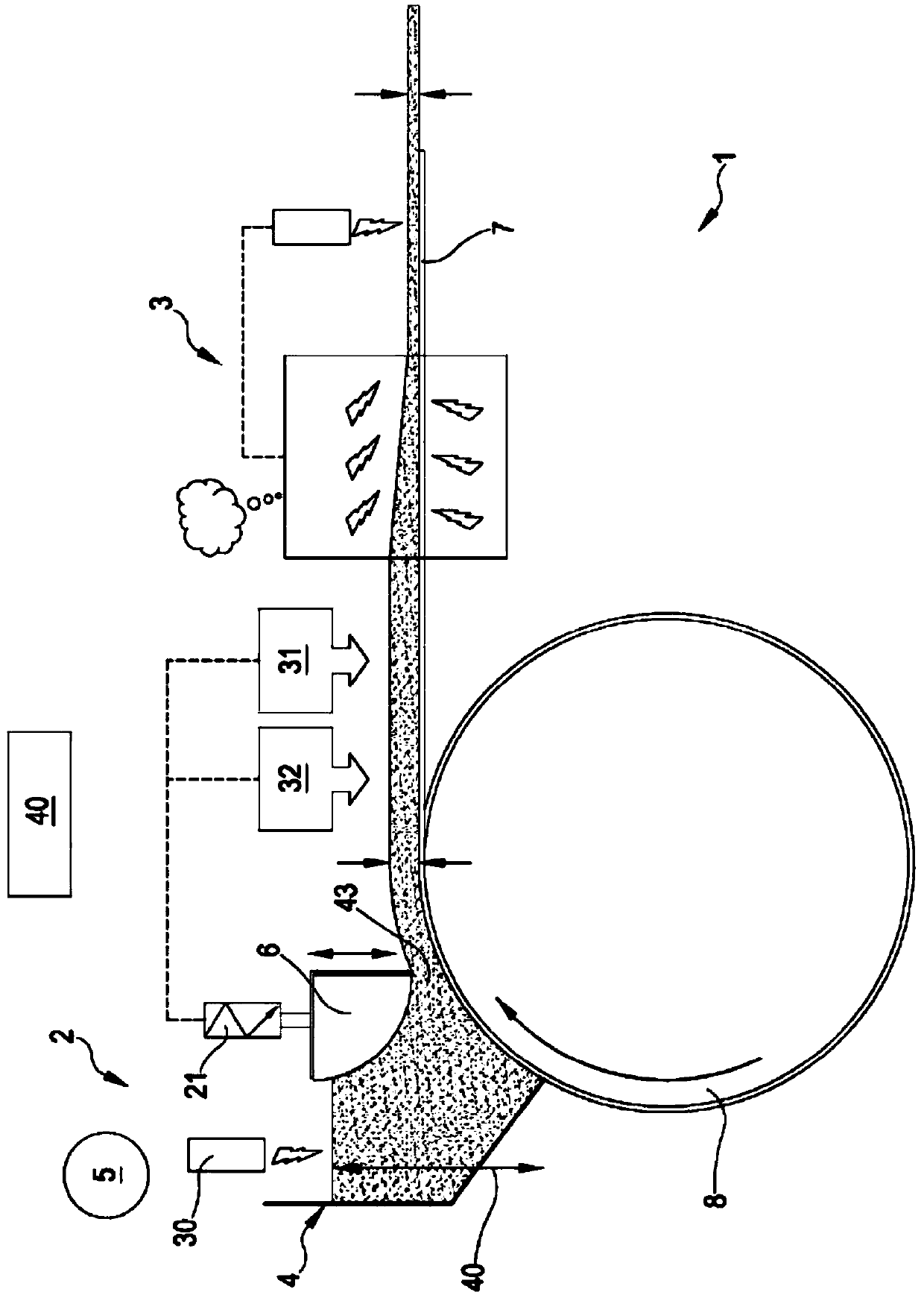

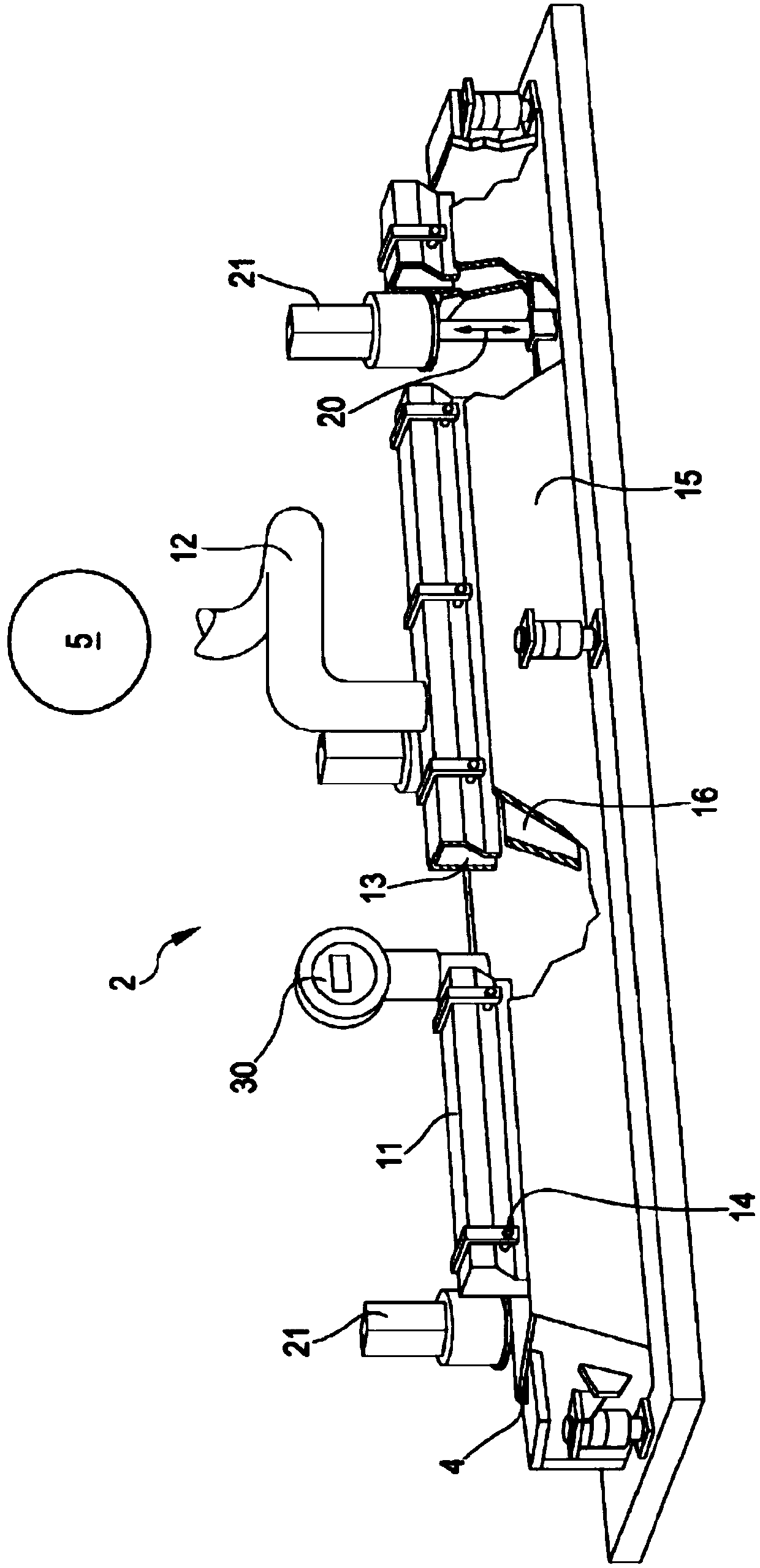

[0067] first reference figure 1 , an apparatus for producing a web of homogenized tobacco material according to the invention is denoted and labeled with the reference numeral 1 .

[0068] The device 1 for producing a homogenized tobacco material web comprises a casting device 2 realized according to the invention and preferably also comprises a drying device downstream of the casting device 2 in the direction of movement of the homogenized tobacco material web 3.

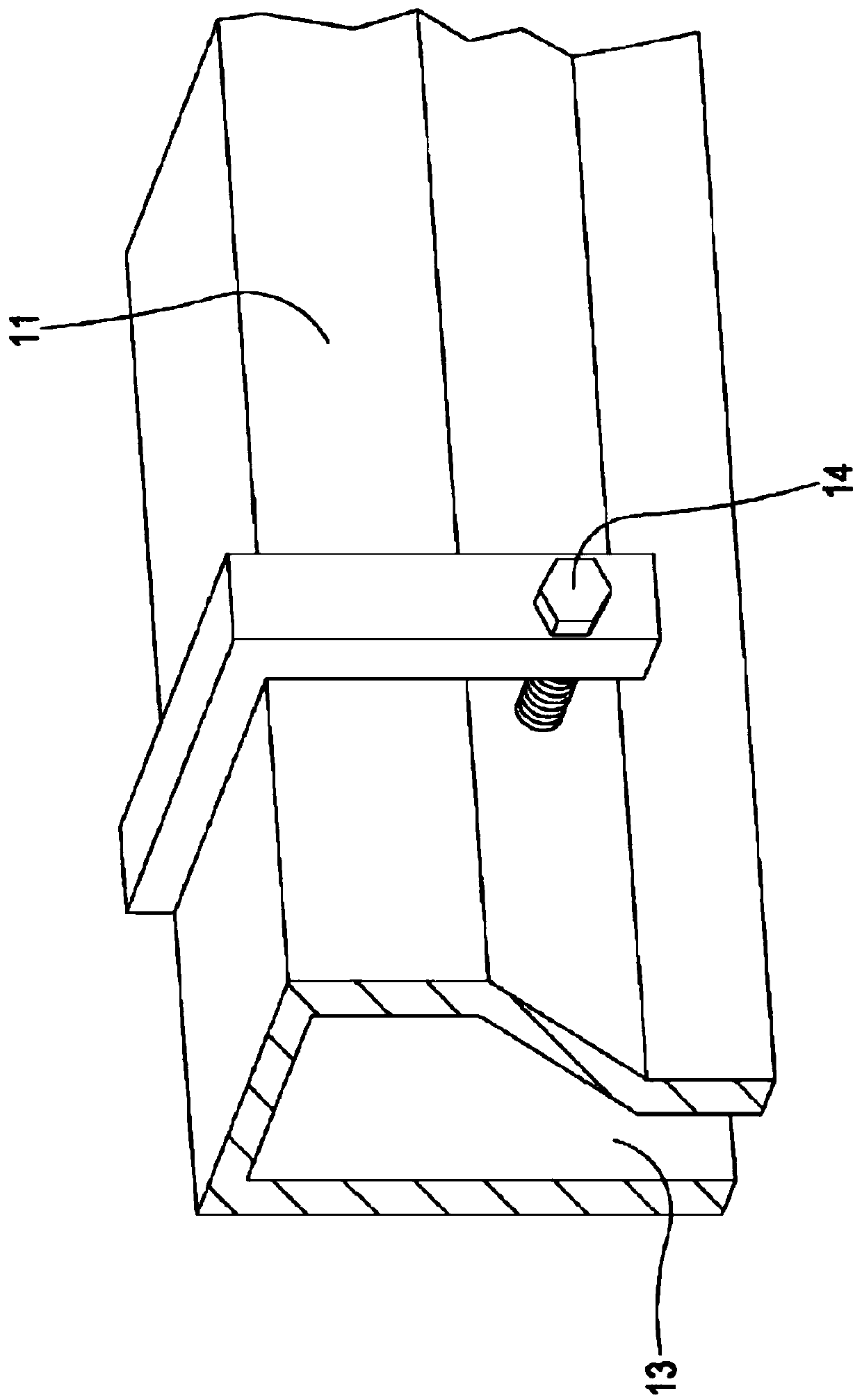

[0069] The casting device 2 comprises: a casting box 4 into which slurry for forming a homogenized web of tobacco material is introduced; a pump 5 ; a casting blade 6 ; and, a movable support 7 . The casting box 4 may have any geometric shape and, in the depicted embodiment, is substantially prismatic. The casting box has an opening 43 corresponding to its bottom and the opening extends along the width of the casting box. The slurry from the buffer tank (not shown in the figure) is transferred by the pump 5 into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical width | aaaaa | aaaaa |

| Average distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com