Ecological permeable pavement brick and preparation method thereof

A permeable brick and ecological technology, applied in the field of pavement ecological permeable bricks and its preparation, can solve the problems of high cost of permeable bricks, coarse surface particles, and few places for application, and achieve excellent water permeability, simplified production process, and resource saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention relates to a pavement ecological permeable brick and a preparation method thereof, comprising aggregate, powder material and organic binder. Mineral granules and solid wastes are used as aggregates, powdered materials and organic binders in a certain particle size range are added, the ratio of raw materials is optimized and adjusted, after granulation, they are stacked and formed, and fired under certain conditions to prepare Porous permeable bricks, observe and test performance parameters such as firing temperature, porosity and density of permeable bricks.

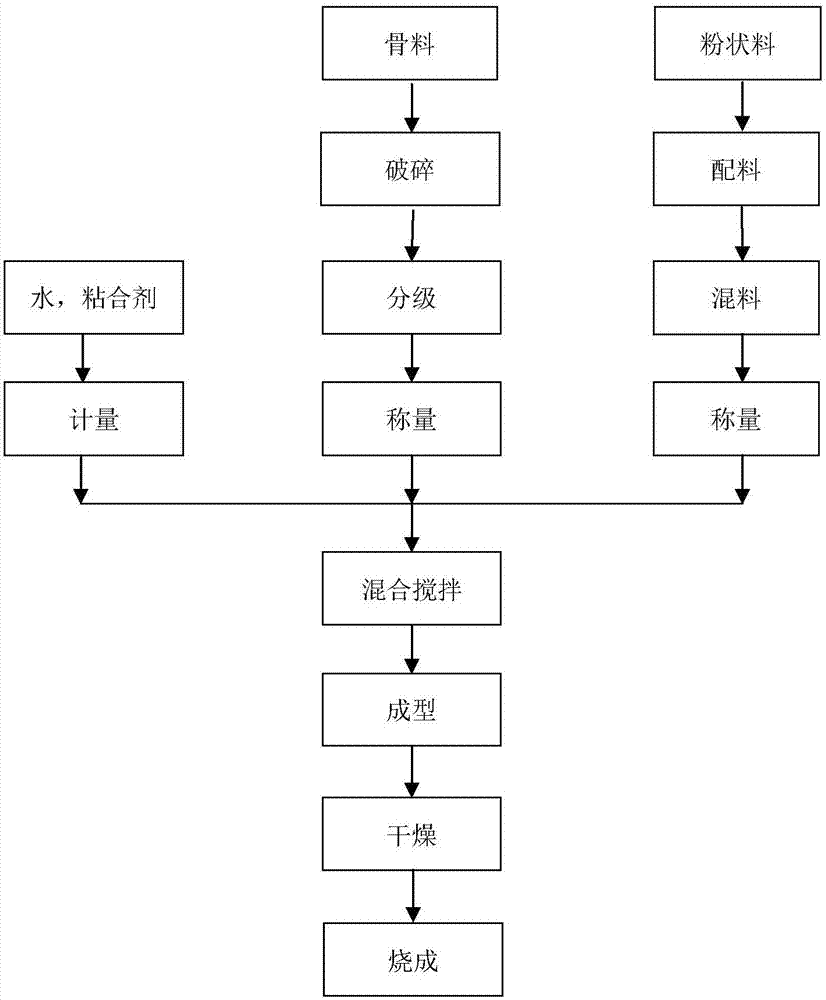

[0025] see figure 1 ,Specific steps are as follows:

[0026] (1) After the waste glass is ground, it is then sieved and graded to screen out four-grade glass particles of 8 mesh or more, 8-20 mesh, 20-40 mesh and 40-80 mesh; Sieve classification, sieve out more than 8 mesh, 8-20 mesh, 20-40 mesh or 40-80 mesh and mineral particles;

[0027] (2) In terms of mass percentage, weigh 30% to 60% of mine...

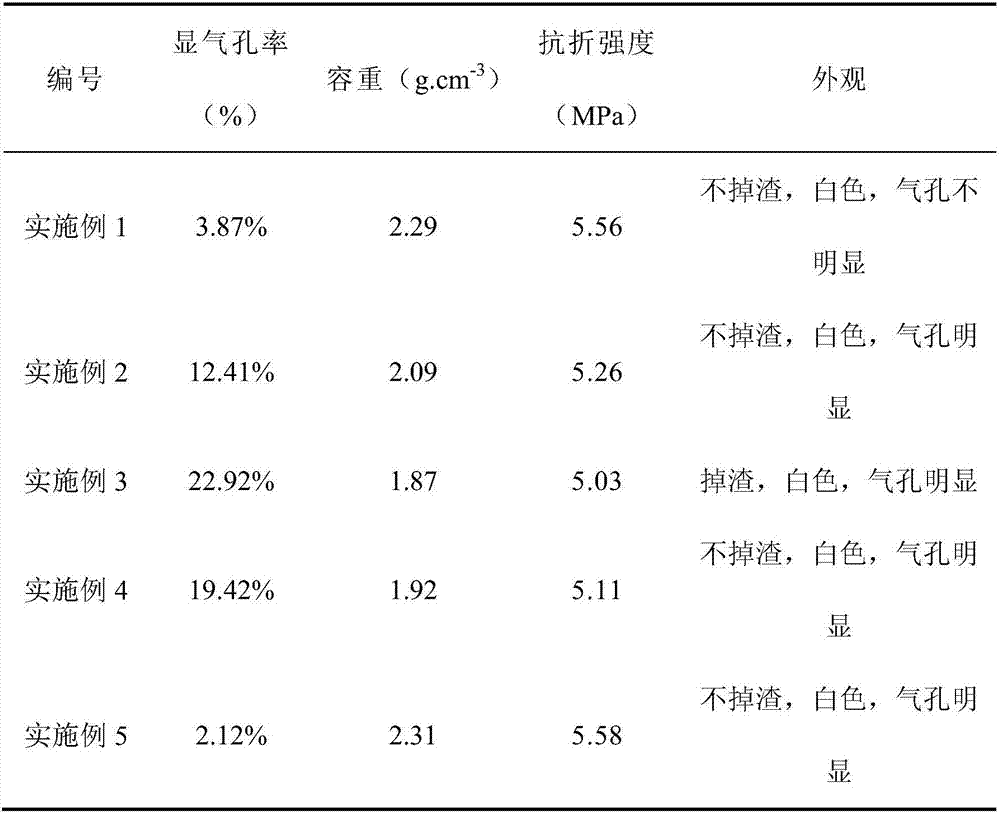

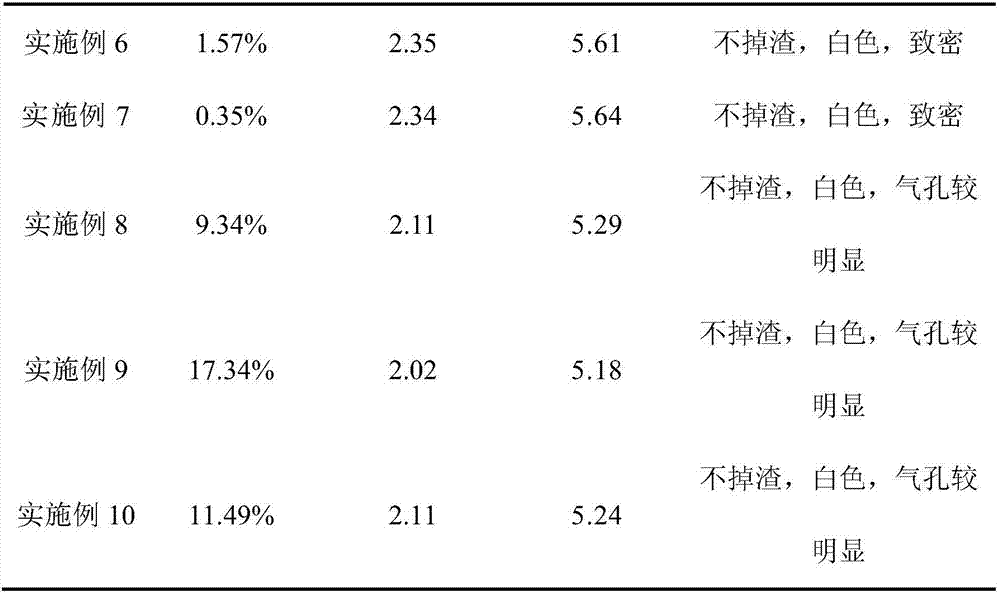

Embodiment 1

[0038] (1) Clean and dry the collected waste glass, crush and grind it, then sieve and classify it, and select 20-40 mesh glass particles; first crush and grind the quartz sand, then sieve and classify it, and select 20-40 mesh quartz sand particles;

[0039] (2) Weigh 70g of glass particles of 20-40 meshes and 30g of quartz sand particles of 20-40 meshes, mix and stir evenly to obtain a mixture, put the mixture into a mold, accumulate and form by natural accumulation, and then dry naturally After that, it is placed in a firing furnace and fired at 860°C for 1 hour, and then cooled naturally to room temperature to obtain pavement ecological permeable bricks.

Embodiment 2

[0041] (1) Wash and dry the collected waste glass, crush and grind it, then sieve and classify it, and select 20-40 mesh glass particles; first crush and grind the selected quartz sand, then sieve and classify it, and select 20-40 mesh Quartz sand particles;

[0042] (2) Weigh 60g of glass particles and 40g of quartz sand particles and mix and stir evenly to obtain a mixture, put the mixture into a mold, accumulate and form by natural accumulation, then place it in a firing furnace after natural drying at 860 Burn at ℃ and keep warm for 30 minutes, then cool naturally to room temperature to make pavement ecological permeable bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com